2.Servo-controlled fixed-length measurement ensures high accuracy and consistency in cutting.

3.Equipped with a scrap collection bin for centralized collection of leftover materials.

4.Three-position finished product storage bin supports centralized collection of various specifications.

5.The storage bin is equipped with a steel chain for collection, reducing noise during the collection process.

6.Optional automatic raw material feeding system reduces the labor intensity of feeding operations.

7.Optional automatic installation of thread protection caps is available, integrating processes and saving labor costs."

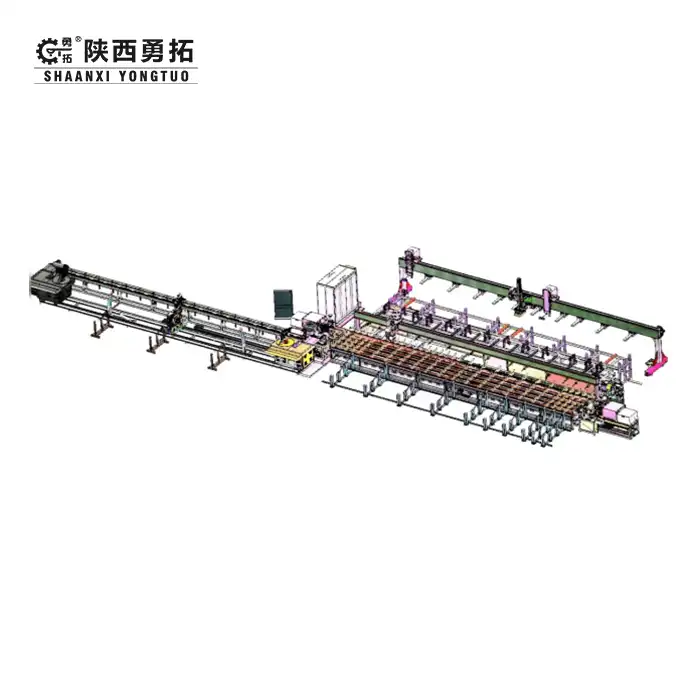

Shaanxi Yongtuo: Your Trusted Steel Bar Sawing and Threading Assembly Line Partner

Shaanxi Yongtuo Machinery Technology Co., Ltd, established in 2003, specializes in designing Steel Bar Sawing and Threading Assembly Lines that combine cutting-edge automation, energy efficiency, and unmatched reliability. With 37 patents, a dedicated R&D team, and 20+ years of global export experience, we deliver turnkey solutions trusted by builders in 30+ countries.

Why Choose Us?

✅ 20+ Years of Expertise: Mature R&D and strict ISO 9001 quality control.

✅ End-to-End Support: Pre-sales planning, installation training, and 24/7 after-sales service.

✅ Proven Performance: 98% on-time delivery rate and ≤12-hour fault response.

✅ Customizable Solutions: Adaptable to diverse project needs (e.g., high-volume processing).

✅ Cost Efficiency: Energy-saving designs reduce operational expenses by up to 30%.

Key Features & Benefits

- Servo-Controlled Cutting: ±0.1mm precision for error-free threading and sawing.

- Automated Scrap Management: Centralized bins minimize waste and cleanup time.

- Three-Position Storage: Organize multiple rebar sizes (Φ12mm–Φ40mm) effortlessly.

- Low-Noise Collection: Steel-chain conveyors operate below 75 dB.

- Optional Add-Ons: Auto feeding systems and thread cap installers save labor.

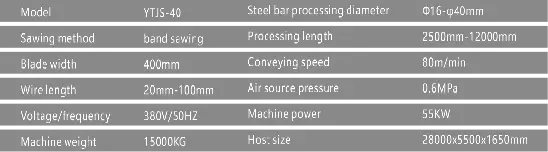

Technical Parameters

|

|---|

Application Areas

Ideal for bridges, tunnels, prefabricated buildings, and high-speed rail projects. Compatible with carbon steel, stainless steel, and high-strength rebar.

Customization Options

- Material Handling: Adjust for extreme climates (e.g., humidity-resistant components).

- IoT Integration: Remote monitoring and predictive maintenance alerts.

- Output Scaling: Configure for 5–50 tons/hour production needs.

Certifications

🔹 CE Certified 🔹 ISO 9001 🔹 SGS Audited

After-Sales Service

- 24/7 remote diagnostics.

- On-site maintenance within 12 hours (domestic).

- 2-year warranty + lifetime technical support.

Packaging & Delivery

Reinforced wooden crates with waterproofing are our go - to solution for safe global shipping. These crates are constructed from thick, durable wood planks that are fastened together with heavy - duty nails and brackets, providing robust structural integrity. A special waterproof coating is then applied to the exterior, creating a reliable barrier against rain, humidity, and splashing water during transit. This ensures that your valuable goods, whether they're delicate electronics or sturdy machinery parts, remain dry and intact throughout their journey across the globe. Inside, shock - absorbing materials like foam inserts or air - filled cushions are carefully placed to protect items from impacts and vibrations. With these features, you can trust that your shipments will reach their destination in perfect condition, no matter how long or arduous the route may be.

Company Profile

Founded in 2003, Shaanxi Yongtuo has been a trusted partner for clients in construction, mining, and heavy machinery sectors. Over the years, we've built a reputation for delivering high - quality products and services. Our sprawling 200 - acre factory in Xi'an is a testament to our capabilities. The state - of - the - art CNC machining centers here churn out precision parts with remarkable accuracy. Meanwhile, our rigorous QA labs, equipped with advanced testing equipment, ensure that every item leaving our facility meets the strictest quality standards, further solidifying our standing in the industry.

Global Clients & Exhibitions

By visiting our booth, you can interact with our team, learn more about our contribution to these projects, and explore how we can tailor our innovative products and services to your future building and infrastructure needs. Don’t miss this opportunity to network and explore potential collaborations at the forefront of the industry.

FAQs

Q: Can this assembly line process curved rebar?

A: Yes! Our modular design supports custom bending attachments.

Q: Do you offer financing options?

A: Flexible terms include leasing and installment plans.

Q: How long is delivery?

A: Standard units ship in 30 days; expedited options available.

Q: Is training included?

A: Free on-site training for operation and maintenance.

Q: Compliance with EU safety standards?

A: Full CE certification ensures seamless EU market access.

Contact Us

📧 Email: sxyongtuo@gmail.com

Upgrade Your Productivity Today with Shaanxi Yongtuo's Steel Bar Sawing and Threading Assembly Line – Where Innovation Meets Reliability.

YOU MAY LIKE

_1744680888628.png)