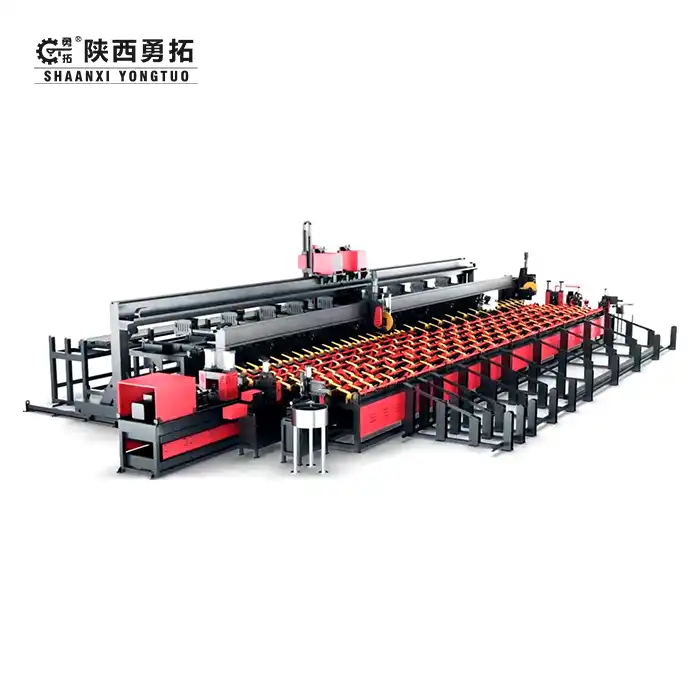

2.Servo-controlled length measurement, with high precision and good consistency in material cutting.

3.Single-bar sawing method allows for multi-task processing.

4.Disc saw cutting,with fast speed and smooth cut surfaces.

5.Servo threading machine, featuring low noise and high speed.

6.Equipped with a scrap collection box to centrally collect leftover material.

7.Three-position finished product collection bin to accommodate centralized collection of various specifications.

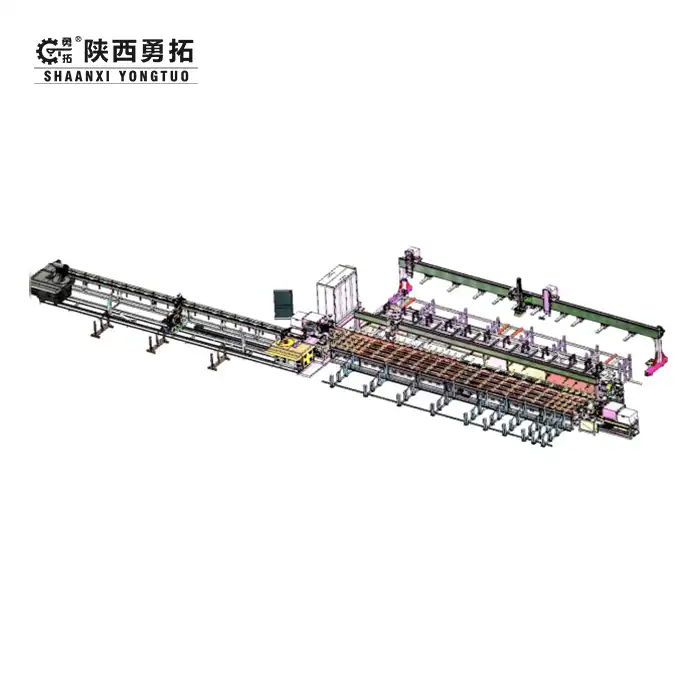

8.Equipped with three sets of three-axis robots for bending material feeding and finished product collection.

9.The bending rotation speed can be set arbitrarily, offering greater processing flexibility.

10.The planetary reducer is used for torque transmission during bending, ensuring low noise, high precision, and long service life.

11.Optional automatic raw material feeding system is available, reducing the labor intensity of feeding operations."

Shaanxi Yongtuo: Your Trusted Partner

Shaanxi Yongtuo Machinery Technology Co., Ltd, established in 2003, is a leading Clever Steel Bar Chilled Cutting Threading and Bending Production System manufacturer. With 37 patents, an original factory, and a 20-year export legacy, we deliver advanced, energy-saving solutions trusted by global infrastructure giants like China Railway Group and Sinohydro.

Why Choose Us?

✅ 37 Valid Patents: Cutting-edge R&D ensures technological leadership.

✅ 24/7 Global Support: ≤12-hour fault response, on-site maintenance.

✅ ISO & CE Certified: Compliant with ASTM, ISO, and GB/T standards.

✅ Cost Efficiency: Reduce labor costs by 40% and processing waste by 30%.

✅ Custom Integration: Compatible with Tekla, AutoCAD, and ERP systems.

Features & Advantages

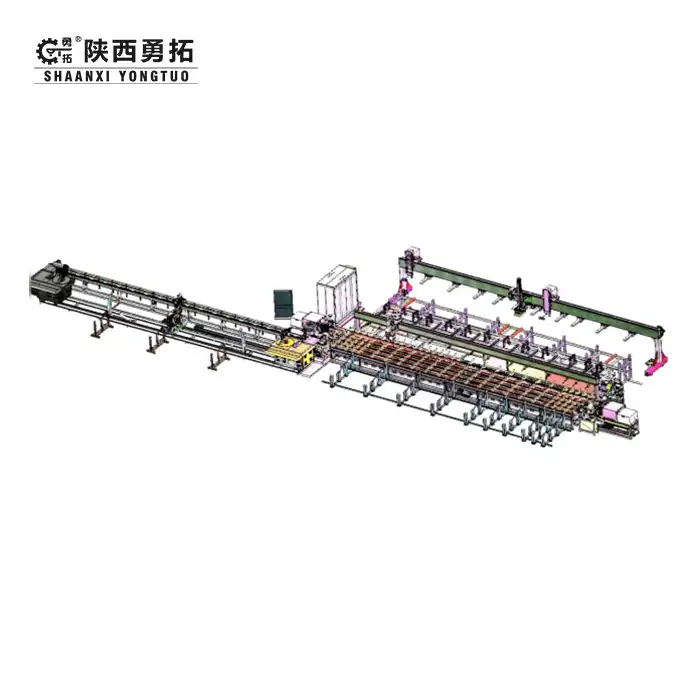

- All-in-One Automation: Feeding, sizing, sawing, threading, bending, and collection in one machine.

- ±0.1mm Precision: Servo-controlled length measurement for perfect consistency.

- Cold Cutting Technology: Preserve HRB500 steel strength with disc saws (1,500 cuts/hour).

- Smart Bending: Planetary reducers enable 0.5° angle accuracy and 10D bend radii.

- Scrap Management: Centralized collection boxes and 3-axis robots for zero material waste.

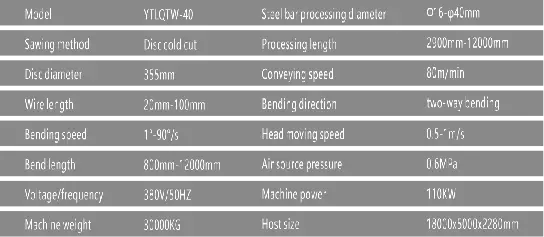

Technical Parameters

Application Areas

- High-Rise Buildings: Reinforced concrete beam processing.

- Prefab Factories: Batch production of staircase reinforcement cages.

- Railways/Bridges: ASTM-compliant threaded rebars for seismic zones.

- Shipbuilding: Custom curved steel bars for hull structures.

Customization Options

- Material Feeding: Add automatic loading systems for 24/7 operation.

- Software: Integrate with MES for real-time production tracking.

- Climate Adaptations: Winter-grade hydraulic oil for -15°C environments.

Certifications

ISO 9001, CE, and GB/T 1499.2-2018 certified. Approved for LEED green building projects.

After-Sales Service

- 24-hour remote diagnostics.

- 3-year core component warranty.

- On-site training for operators.

Packaging

Our sea - worthy wooden crates are engineered to withstand the harsh conditions of ocean voyages. Each crate is coated with a high - quality anti - rust finish, protecting the wood from saltwater corrosion and ensuring long - lasting durability. This not only safeguards the integrity of the crate but also the valuable cargo it holds. Additionally, we've incorporated QR code tracking technology. By simply scanning the code, you can monitor the real - time location of your shipment throughout its journey. Whether your goods are en route to a port on the other side of the world or in transit between distribution centers, this feature provides transparency and peace of mind, making our shipping solutions both secure and convenient.

About Shaanxi Yongtuo

Our 500+ strong workforce, spread across a vast 20,000㎡ factory, forms the backbone of our success. Leveraging their skills and dedication, we've had the privilege of serving 1,200+ clients across 60 countries.

FAQ

Q: How does cold cutting prevent material strength loss?

A: Our disc saws operate below 150°C, avoiding phase changes in high-strength steel.

Q: Can the system handle non-standard bend angles?

A: Yes! Servo-driven bending allows 1°–180° customization.

Q: Is production data exportable for audits?

A: CSV/PDF logs of cutting lengths, angles, and timestamps are auto-generated.

Q: What's the ROI timeframe?

A: Clients typically achieve payback in 14 months via labor and material savings.

Q: Do you provide installation videos?

A: Yes – multilingual video guides and live WhatsApp support are available.

Contact Us Today!

📧 Email: sxyongtuo@gmail.com

Clever Steel Bar Chilled Cutting Threading and Bending Production System – Engineered for Excellence, Trusted Worldwide.

YOU MAY LIKE

_1744680888628.png)