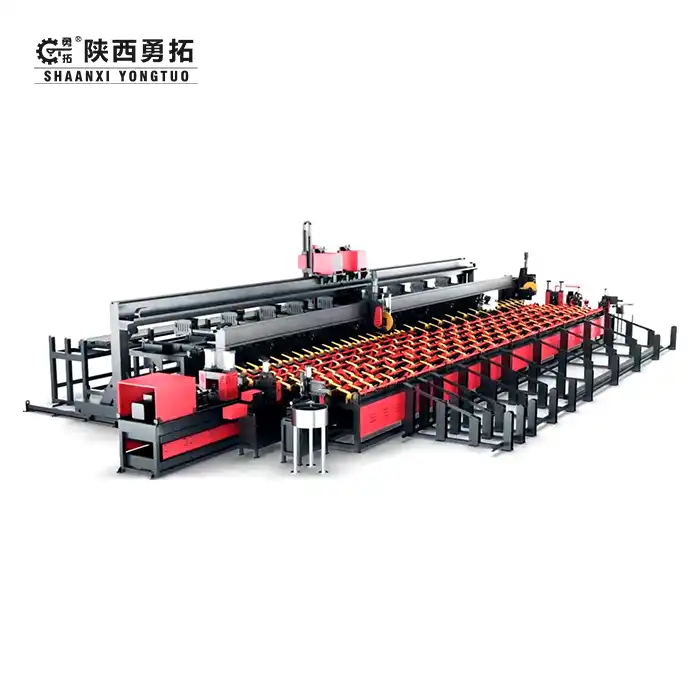

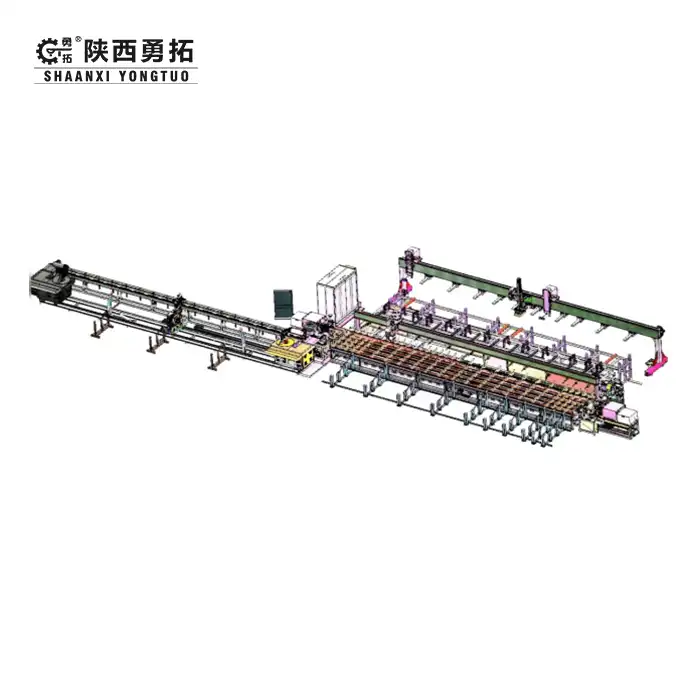

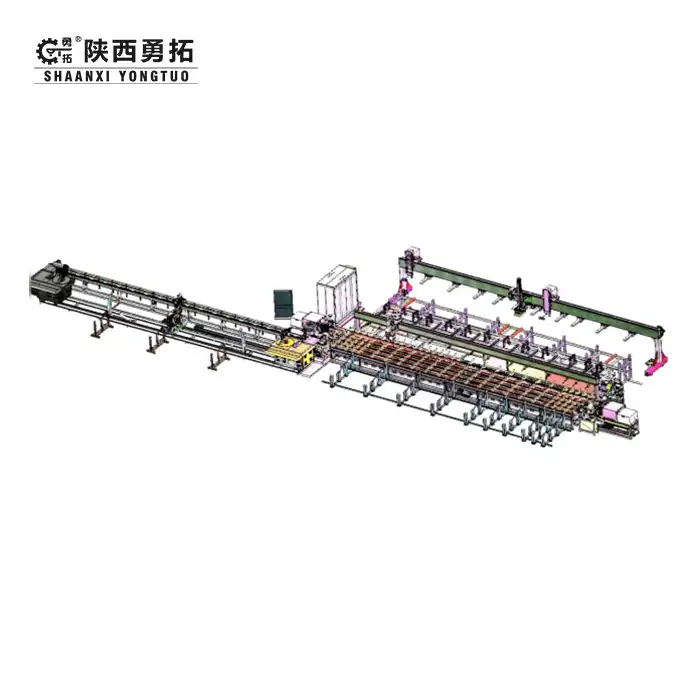

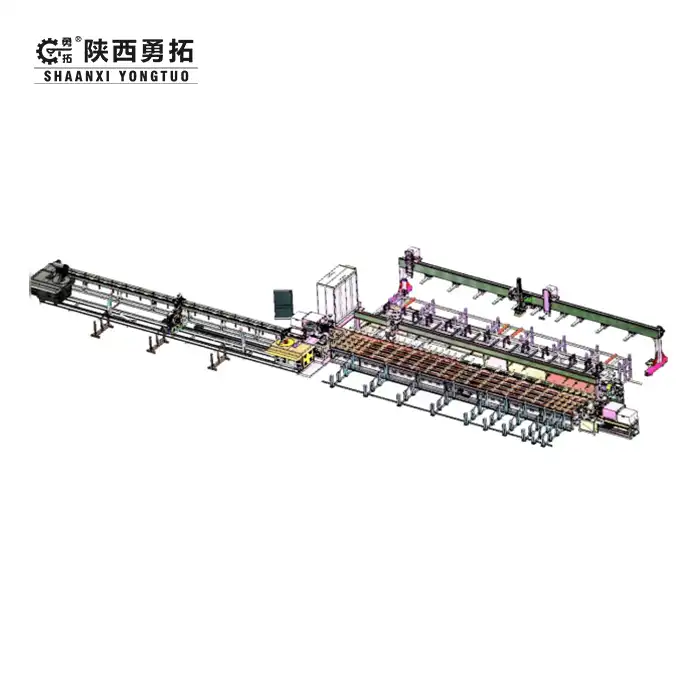

2.Servo-controlled length measurement, with high precision and good consistency in material cutting.

3.Single-bar sawing method allows for multi-task processing.

4.Disc saw cutting, with fast speed and smooth cut surfaces.

5.Servo threading machine, featuring low noise and high speed.

6.Equipped with a scrap collection box to centrally collect leftover material.

7.Three-position finished product collection bin to accommodate centralized collection of various specifications.

8.The collection bin is equipped with a steel chain for collection, reducing noise during collection.

9.Optional automatic raw material loading device to reduce the labor intensity of loading work.

10.Optional automatic installation device for thread protectors, streamlining processes and saving labor."

Shaanxi Yongtuo Machinery Technology Co., Ltd: Your Trusted Partner

As a leading Smart Cold Cutting and Threading Manufacturing Line manufacturer since 2003, Shaanxi Yongtuo combines advanced CNC technology, 37 patents, and 20+ years of global expertise. Our solutions deliver energy-saving operation, unmatched precision (±0.01mm), and ISO-certified quality, backed by 24/7 support.

Why Choose Us?

✅ Proven Expertise: 20+ years in R&D, serving 50+ countries.

✅ End-to-End Support: Pre-sales planning to 24-hourFailureResponse

✅ Customization: Adapt to API/ASME standards or unique specs.

✅ Cost Efficiency: 30% energy savings vs.Traditional thermal cutting equipment.

✅ Global Compliance: CE, ISO 9001, and API Q1 certifications.

Key Features & Advantages

- Precision Servo Control: High-accuracy length measurement (±0.1mm) for consistent cuts.

- Disc Saw Cutting: 3x faster than traditional bandsaws, smooth finishes.

- Multi-Task Processing: Single-bar sawing handles threading, milling, and cutting simultaneously.

- Noise Reduction: Scrap collection box + steel chain bins (≤75dB).

- Automation Options: Add raw material loaders or thread protector installers.

Product Parameters

Application Areas

- Oil & Gas: API-standard pipe threading.

- Construction: High-speed rebar processing (±0.2mm tolerance).

- Aerospace: Titanium alloy Cold cutting, no thermal deformation.

- Automotive: Processing of multi-specification drive shafts.

Customization Options

- Add-Ons: Automatic raw material loading, thread protector installation.

- Software Integration: Compatible with MES/ERP systems for real time protection.

- Language Support: Localized HMI interfaces (English, Russian, Arabic).

Certifications

ISO 9001, CE, API Q1, and GOST-R.

After-Sales Service

- 24/7 remote diagnostics.

- On-site support within ≤12 hours (domestic).

- 2-year warranty + lifetime technical guidance.

Packaging

Our waterproof wooden crates, crafted from premium - grade timber, are a paragon of reliability for protecting your precious items. The outer surface is meticulously treated with a high - quality waterproof coating, creating an impermeable shield against rain, humidity, and even splashes during transportation. Inside, shock - absorbent foam lines every inch of the crate. This foam, engineered for maximum cushioning, acts as a safeguard, minimizing the impact of any bumps, jolts, or vibrations that the crate might encounter during its journey.

About Shaanxi Yongtuo

Since our establishment in 2003, we've emerged as a driving force in the industry, empowering over 1,200 clients across 50+ countries with our patented machinery. Our 20,000㎡ factory is a paragon of modern manufacturing. The integration of AI - quality testing ensures that every product leaving our facility meets the highest standards. With IoT - enabled production, we can monitor and optimize processes in real - time, enhancing efficiency and reducing downtime. This technological prowess, combined with years of experience, allows us to continuously deliver solutions that not only meet but exceed our clients' expectations on a global scale.

Customer Visits & Exhibitions

These exhibitions provided us with a platform to interact with global clients, demonstrate our product capabilities, and gain valuable insights. Our participation at these events underscores our commitment to being at the forefront of industry innovation and meeting the diverse needs of our international customer base.

FAQ

Q: Can this Smart Cold Cutting and Threading Manufacturing Line process titanium alloys?

A: Yes! Our cold cutting technology retains material integrity even for Grade 5 titanium alloy.

Q: What's the lead time?

A: 30-45 days after deposit, expedited options available.

Q: Do you provide training?

A: Free 3-day onsite training + multilingual manuals.

Q: How to handle maintenance?

A: Predictive maintenance alerts via Yongtuo IoT system.

Q: Customization cost?

A: Tailored quotes within 24 hours.

Contact Us for Your Smart Cold Cutting and Threading Manufacturing Line

📧 Email: sxyongtuo@gmail.com

Optimized for Your Success

Shaanxi Yongtuo – Where Precision Meets Innovation in the Smart Cold Cutting and Threading Manufacturing Line.

YOU MAY LIKE

_1744680888628.png)