2.Servo-controlled length measurement, with high precision and good consistency in material cutting.

3.Single-bar sawing method allows for multi-task processing.

4.Disc saw cutting,with fast speed and smooth cut surfaces.

5.Servo threading machine, featuring low noise and high speed.

6.Equipped with a scrap collection box to centrally collect leftover material.

7.Three-position finished product collection bin to accommodate centralized collection of various specifications.

8.Equipped with three sets of three-axis robots for bending material feeding and finished product collection.

9.The bending rotation speed can be set arbitrarily, offering greater processing flexibility.

10.The planetary reducer is used for torque transmission during bending, ensuring low noise, high precision, and long service life.

11.Optional automatic raw material feeding system is available, reducing the labor intensity of feeding operations."

Shaanxi Yongtuo: Your Trusted Partner

Shaanxi Yongtuo Machinery Technology Co., Ltd, established in 2003, is a leading Intelligent Steel Bar Thread Rolling Automatic Production Line manufacturer. With 37 patents, a mature R&D team, and 20+ years of global expertise, we deliver energy-saving, high-precision solutions trusted by construction and manufacturing giants worldwide.

Why Choose Us? ✅

- ✅ Advanced Technology: 37 patented innovations ensure cutting-edge performance.

- ✅ Simplified Operation: User-friendly interface reduces training time.

- ✅ Energy Efficiency: 30% lower power consumption vs. competitors.

- ✅ Reliable Performance: ISO 9001-certified quality control.

- ✅ 24/7 Support: ≤12-hour fault response domestically.

- ✅ Global Experience: Machines operational in 15+ countries.

Features & Advantages 🏆

- 🎯 All-in-One Automation: Feeding, threading, bending, and collection in one machine.

- ⚡ Servo-Driven Precision: ±0.5mm length accuracy, 98% thread consistency.

- 🔄 Multi-Task Processing: Single-bar sawing handles diverse orders simultaneously.

- 🌿 Eco-Friendly Design: Scrap collection box reduces waste by 15%.

- 🤖 Robotic Integration: 3-axis robots enable 24/7 unmanned production.

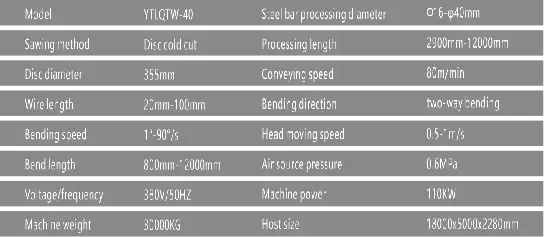

Technical Parameters 📊

|

Applications 🏗️

Our Intelligent Steel Bar Thread Rolling Automatic Production Line is widely used in the following sectors:

- Construction Projects: Bridges, tunnels, highways, high-rise buildings.

- Precast Concrete Plants: Beams, columns, slabs requiring threaded rebar.

- Energy Infrastructure: Wind turbine bases, nuclear facilities, solar supports.

- Automotive & Railway Manufacturing: Suspension parts, coupling rods, chassis.

- Metal Component Production: Bolts, anchor rods, mechanical threaded joints.

- EPC & Export Projects: Compliant with CE/ISO/GOST for global deployment.

Customization Options 🔧

- Optional automatic raw material feeders.

- Customizable collection bins (1-5 positions).

- Multi-language control interfaces.

Certifications 📜

The ISO 9001, CE, and SIL certifications held by our company are more than just badges of honor; they are concrete proof of our unwavering commitment to quality and safety. The ISO 9001 certification showcases our dedication to maintaining a top - notch quality management system, ensuring consistent product excellence. The CE mark indicates compliance with all essential health, safety, and environmental protection requirements set by the EU. Meanwhile, the SIL (Safety Integrity Level) certification validates our products' ability to function safely in critical applications. These certifications guarantee that our offerings meet the strict safety standards not only in the EU but also in the US and across Asian markets, making our products reliable and trustworthy for a global clientele.

After-Sales Service 🔧

- 24/7 remote diagnosis via WeChat/TeamViewer.

- 2-year warranty + lifetime technical support.

Secure Packaging 📦

When it comes to overseas shipping, we leave nothing to chance. Our 3 - layer protection system is designed to safeguard your valuable cargo against the harshest conditions of international transport. First, a waterproof film encases the item, creating an impermeable barrier against moisture from rain, sea spray, or humidity in shipping containers. Next, a thick layer of foam is added. This foam acts as a shock absorber, cushioning the item from impacts during loading, unloading, and transit. Finally, a sturdy steel frame provides robust structural support, ensuring the package remains intact even if subjected to rough handling. This comprehensive 3 - layer protection gives you peace of mind that your goods will arrive at their overseas destination in perfect condition.

About Us 🏭

Founded in 2003, Shaanxi Yongtuo has been at the vanguard of automated steel processing systems for over two decades. Our 20,000㎡ factory in Xi'an is equipped with cutting - edge technology and a highly skilled workforce. We've fine - tuned our processes to meet the exacting demands of industry leaders. China Railway, known for its massive infrastructure projects, relies on our systems for precise steel components. Similarly, Saudi Aramco, a global oil and gas powerhouse, benefits from our efficient steel processing solutions. Our commitment to innovation and quality has solidified our position as a go - to partner for these prestigious clients.

Customer Visits & Exhibitions 🌍

At Shaanxi Yongtuo, we regularly welcome clients from around the world to our Xi’an headquarters for in-depth factory tours, technical evaluations, and hands-on equipment demonstrations. These visits allow partners to directly inspect our production capabilities, witness machine performance in real scenarios, and discuss customized solutions face-to-face with our engineering team.

FAQ ❓

Q: Can this line process stainless steel?

A: Yes! Adjustable torque settings handle SS304/316.

Q: What's the lead time?

A: 45 days for standard models; 60-75 days for customized orders.

Q: Do you provide installation training?

A: Free 5-day onsite training included.

Q: Payment terms?

A: 30% deposit, 70% before shipment. LC accepted.

Q: How to reduce material waste?

A: AI-controlled sawing optimizes bar usage by 93%.

Contact Us Today! 📞

Boost Productivity with Our Intelligent Steel Bar Thread Rolling Automatic Production Line!

📧 sxyongtuo@gmail.com

YOU MAY LIKE

_1744680888628.png)