2.Servo-controlled length measurement, with high precision and good consistency in material cutting.

3.Single-bar sawing method allows for multi-task processing.

4.Disc saw cutting,with fast speed and smooth cut surfaces.

5.Servo threading machine, featuring low noise and high speed.

6.Equipped with a scrap collection box to centrally collect leftover material.

7.Three-position finished product collection bin to accommodate centralized collection of various specifications.

8.Equipped with three sets of three-axis robots for bending material feeding and finished product collection.

9.The bending rotation speed can be set arbitrarily, offering greater processing flexibility.

10.The planetary reducer is used for torque transmission during bending, ensuring low noise, high precision, and long service life.

11.Optional automatic raw material feeding system is available, reducing the labor intensity of feeding operations."

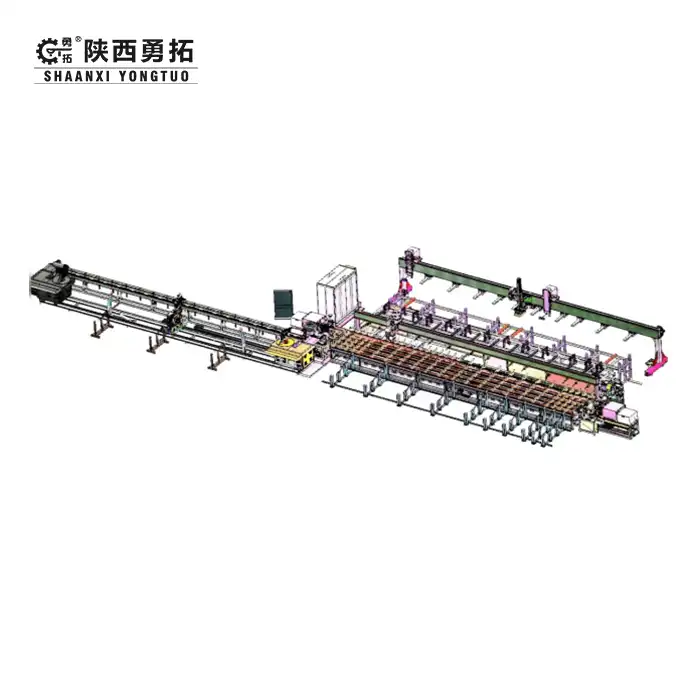

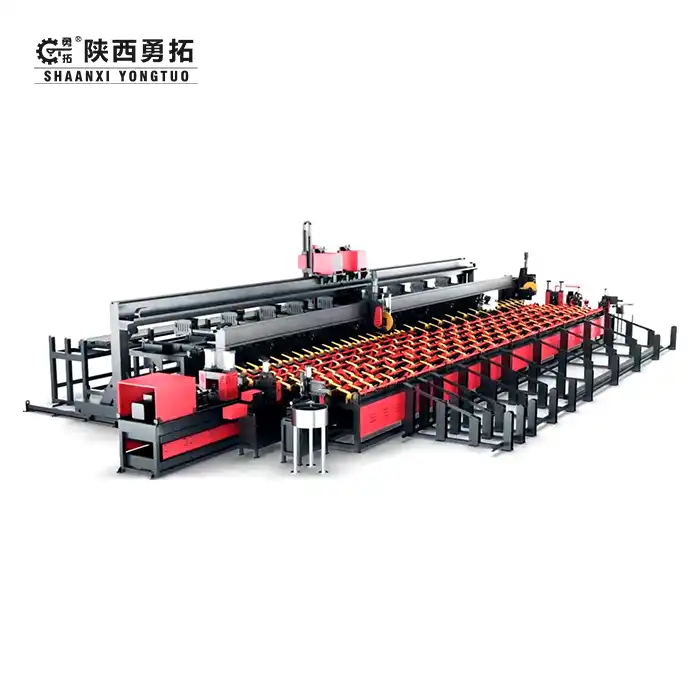

Shaanxi Yongtuo Machinery Technology Co., Ltd – Innovating Smart Rebar Fabrication

Shaanxi Yongtuo Machinery Technology Co., Ltd, established in 2003, is a trusted manufacturer of the Smart Rebar Fabrication and Threading Line. With 37+ patents, a mature R&D team, and ISO-certified production, we deliver advanced, energy-saving, and reliable equipment for global construction and metalworking industries.

Why Choose Our Smart Rebar Fabrication and Threading Line?

✅ Advanced Automation: Feed, size, cut, thread, bend, and collect in one machine.

✅ Precision Engineering: Servo-controlled measurement ensures ±1mm cutting accuracy.

✅ Energy Efficiency: 20% lower power consumption vs. traditional models.

✅ 24/7 Support: On-site maintenance within ≤12 hours (domestic).

✅ 10+ Years Export Experience: Trusted by contractors in 15+ countries.

Features & Advantages

✔️ All-in-One Processing: Eliminate manual handling with integrated sizing, sawing, threading, and bending.

✔️ High-Speed Disc Saw: Cut 60-80 bars/hour with smooth, burr-free surfaces.

✔️ 3-Axis Robots: Automate material feeding and finished product sorting.

✔️ Planetary Reducer: Noise ≤75dB, 50,000-hour lifespan for heavy-duty bending.

✔️ Scrap Collection System: Centralize waste for cleaner worksites.

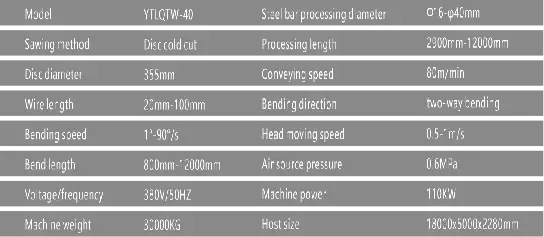

Technical Parameters

|

Application Areas

- Bridge & Tunnel Construction: High-precision rebar for seismic zones.

- Prefab Concrete Plants: Custom bends for beams, columns, and piles.

- High-Speed Rail Projects: Mass production of threaded rebars.

- Commercial Real Estate: Rapid processing for tight deadlines.

Customization Options

- Material Feeding: Add conveyor systems for 50m+ rebar coils.

- IoT Integration: Remote monitoring via Yongtuo's SaaS platform.

- Multi-Language UI: English, Arabic, Spanish control panels.

Certifications

Our Smart Rebar Fabrication and Threading Line hold ISO 9001, CE, and GOST - R certifications, underscoring our unwavering commitment to quality and safety. The ISO 9001 certification showcases our dedication to maintaining a world - class quality management system. The CE mark indicates compliance with EU health, safety, and environmental regulations. GOST - R certification, valid in the Eurasian Economic Union, further broadens our market reach. Additionally, being compliant with ASTM A615/A706 standards, our products meet the rigorous requirements for carbon and low - alloy steel reinforcing bars in the United States. This comprehensive suite of certifications and standards compliance ensures that our offerings are reliable, high - performing, and suitable for a wide range of applications across different global markets.

After-Sales Service

We offer a comprehensive support package to ensure the seamless operation of our products. Our free 3 - day onsite operator training equips your staff with the skills needed to handle our machinery efficiently, reducing the risk of errors and maximizing productivity. For added peace of mind, we provide a 2 - year warranty on critical components, protecting your investment against unforeseen malfunctions.

FAQ

Q: Can this line process international rebar standards (e.g., ASTM, BS)?

A: Yes! Our machines adapt to ASTM, BS4449, and GB1499.

Q: How long does installation take?

A: Our team completes setup in 5-7 days, including testing.

Q: Is raw material feeding automated?

A: Optional robotic arms can load 6-12m rebars automatically.

Q: What's the ROI period?

A: Clients typically recover costs in 8-12 months via labor savings.

Q: Do you provide CAD drawings for custom bends?

A: Yes – share your design, and we'll program the machine.

Contact Us

📧 Email: sxyongtuo@gmail.com

Why Trust Shaanxi Yongtuo?

- 200+ Successful Projects: Including the Jakarta-Bandung HSR and Dubai Expo 2020.

- Factory Tour Welcome: Visit our 20,000㎡ facility in Xi'an, China.

- Live Demos: Test your rebars on our Smart Rebar Fabrication and Threading Line!

YOU MAY LIKE

_1744680888628.png)