2.Servo-controlled length measurement, with high precision and good consistency in material cutting.

3.Single-bar sawing method allows for multi-task processing.

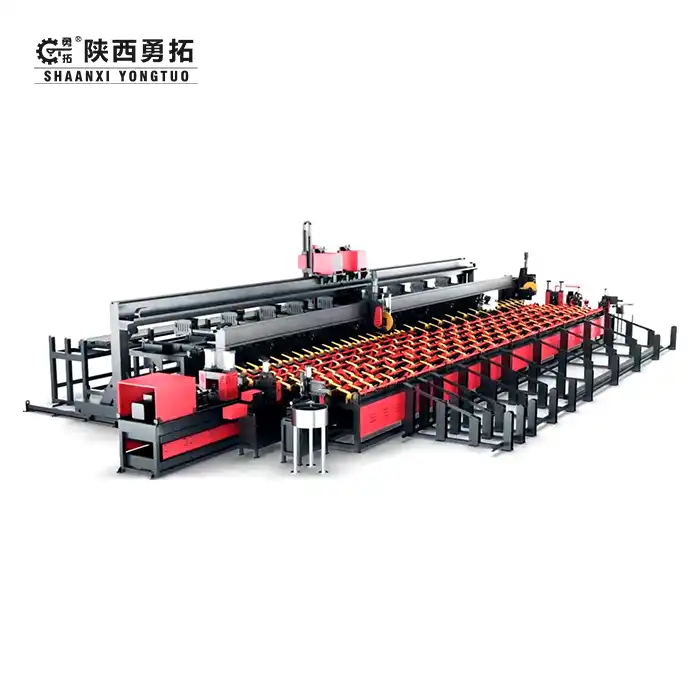

4.Disc saw cutting,with fast speed and smooth cut surfaces.

5.Servo threading machine, featuring low noise and high speed.

6.Equipped with a scrap collection box to centrally collect leftover material.

7.Three-position finished product collection bin to accommodate centralized collection of various specifications.

8.Equipped with three sets of three-axis robots for bending material feeding and finished product collection.

9.The bending rotation speed can be set arbitrarily, offering greater processing flexibility.

10.The planetary reducer is used for torque transmission during bending, ensuring low noise, high precision, and long service life.

11.Optional automatic raw material feeding system is available, reducing the labor intensity of feeding operations."

Shaanxi Yongtuo Machinery Technology Co., Ltd – Your Trusted Partner

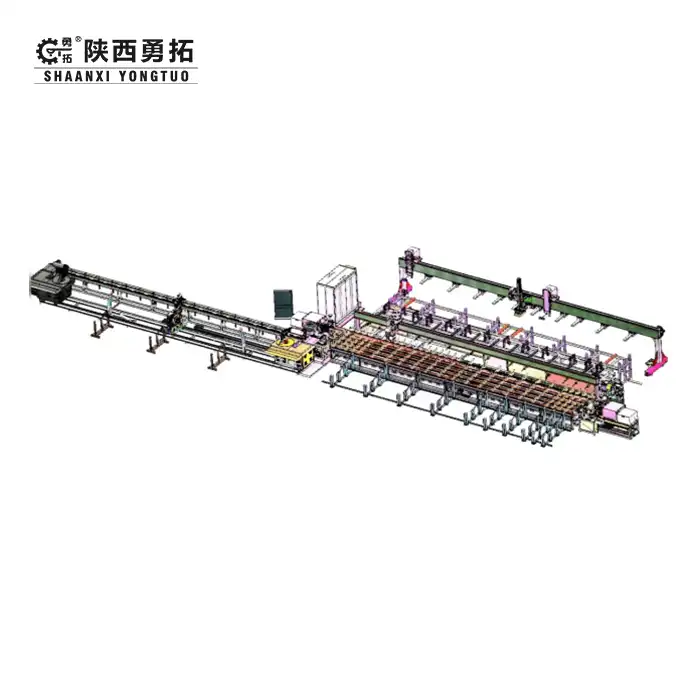

As a leading Smart Rebar Cold Cutting Threading and Bending Manufacturing Line manufacturer and supplier, Shaanxi Yongtuo combines 20+ years of expertise with cutting-edge technology. Our automated systems integrate feeding, sizing, sawing, threading, bending, and collection into one seamless workflow, ensuring energy efficiency, reliability, and compliance with global standards.

Why Choose Us?

✅ 20+ Years of Expertise: Trusted by global clients like China Railway and European prefab manufacturers.

✅ 37 Valid Patents: Core technologies for precision cutting (±0.5mm) and high-speed bending (200+ bars/hour).

✅ 24/7 Support: ≤12-hour fault response with remote diagnostics and on-site maintenance.

✅ Cost-Efficiency: Reduce scrap rates to <1% and energy use by 30% vs. traditional methods.

✅ Customization: Modular designs for IoT integration or phased investment.

Key Features & Advantages

- All-in-One Automation: Feed, cut, thread, bend, and collect in a single machine.

- Servo Precision: ±0.5mm cutting accuracy and ±1° bending angle consistency.

- Multi-Task Processing: Single-bar sawing handles diverse specs (6–40mm diameter).

- Disc Saw Speed: Smooth cuts at 2x traditional speed.

- Low-Noise Threading: Servo-driven operation at ≤75dB.

- Smart Waste Management: Centralized scrap collection and 3-bin sorting.

- Robotic Flexibility: 3-axis robots for automated feeding and stacking.

- Planetary Reducer: Durable torque transmission with 50,000-hour lifespan.

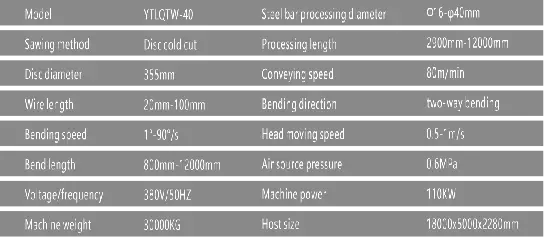

Technical Parameters

|

Application Areas

- High-Speed Rail & Bridges: Process 10,000+ tons of rebar with zero tolerance.

- Prefab Concrete Plants: Automate bending for beams, columns, and slabs.

- Steel Fabricators: Cut threading costs by 40% with servo precision.

- Industrial Complexes: IoT-ready for real-time production monitoring.

Customization Options

- IoT Integration: Cloud-based data analytics for predictive maintenance.

- Raw Material Feeders: Automatic loading systems to reduce labor.

- Regional Adaptations: Dust-proof or humidity-resistant configurations.

Certifications

Our Smart Rebar Cold Cutting Threading and Bending Manufacturing Line is a paragon of quality and regulatory compliance. Holding ISO 9001 certification, it adheres to a world - class quality management system, guaranteeing consistent, high - quality output. The CE mark validates its compliance with EU health, safety, and environmental protection directives. Moreover, the RoHS (Restriction of Hazardous Substances) standard compliance means that our processing line is free from harmful substances, in line with Asian and EU regulations. This ensures that our product not only operates efficiently but also safeguards the environment and the well - being of workers and end - users, making it a trusted choice for construction projects across the globe.

After-Sales Service

- 24/7 Remote Support: Diagnose issues via video call.

- Local Teams: Spare parts delivered within 3 days in China/SEA.

- Training: On-site tutorials for operators and engineers.

Packaging & Shipping

- Waterproof wooden crates with foam cushioning.

- FOB/CIF terms available for global clients.

About Shaanxi Yongtuo

Established in 2003, our journey in the field of automated rebar processing systems has been remarkable. Over the years, we've successfully delivered 500+ such systems to 30+ countries, catering to diverse construction and infrastructure projects worldwide. Our 12,000㎡ factory in Xi'an is a testament to our commitment to quality and innovation. It houses state - of - the - art CNC machining centers, ensuring precision in every component we produce. Additionally, our dedicated R&D lab is constantly exploring new technologies and improvements, enabling us to stay ahead in the industry and provide cutting - edge solutions to our clients.

Customer Visits & Exhibitions

At Shaanxi Yongtuo Machinery Technology Co., Ltd, we actively participate in major construction and machinery exhibitions worldwide and welcome global clients to our Xi’an factory for in-depth cooperation.

FAQ

Q: Can this line process irregularly shaped rebars?

A: Yes! Our servo system auto-adjusts for bends, twists, or uneven surfaces.

Q: What's the ROI timeframe?

A: Typically 12–18 months via labor and waste reduction.

Q: Do you provide BIM integration?

A: Optional IoT modules sync with BIM software for real-time updates.

Q: How long does installation take?

A: 5–7 days with our engineers onsite.

Q: Is financing available?

A: Yes – inquire about leasing or phased payment plans.

Contact Us Today!

Ready to upgrade your rebar processing? Email sxyongtuo@gmail.com for a free consultation.

Shaanxi Yongtuo Machinery – Where Innovation Powers Your Smart Rebar Cold Cutting Threading and Bending Manufacturing Line.

YOU MAY LIKE

_1744680888628.png)