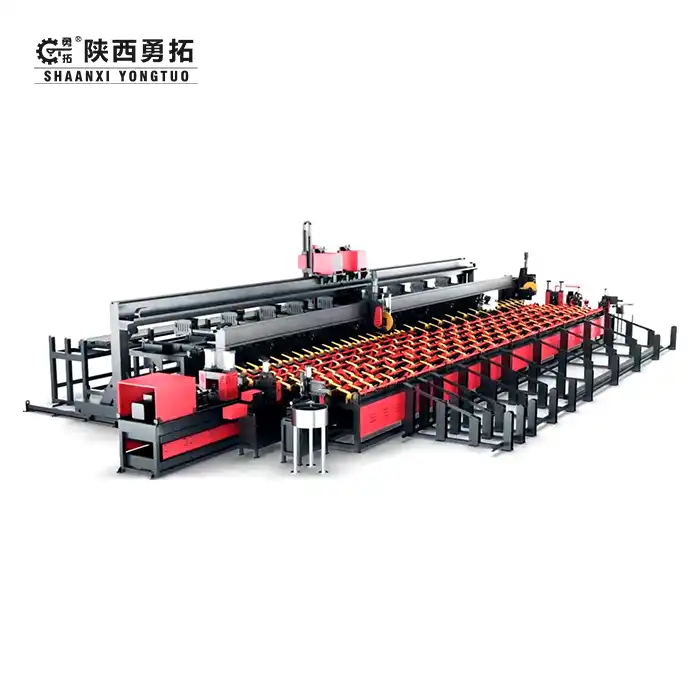

2.Servo-controlled length measurement, with high precision and good consistency in material cutting.

3.Single-bar sawing method allows for multi-task processing.

4.Disc saw cutting,with fast speed and smooth cut surfaces.

5.Servo threading machine, featuring low noise and high speed.

6.Equipped with a scrap collection box to centrally collect leftover material.

7.Three-position finished product collection bin to accommodate centralized collection of various specifications.

8.Equipped with three sets of three-axis robots for bending material feeding and finished product collection.

9.The bending rotation speed can be set arbitrarily, offering greater processing flexibility.

10.The planetary reducer is used for torque transmission during bending, ensuring low noise, high precision, and long service life.

11.Optional automatic raw material feeding system is available, reducing the labor intensity of feeding operations."

Shaanxi Yongtuo: Your Trusted Partner in Automated Steel Processing

Shaanxi Yongtuo Machinery Technology Co., Ltd. specializes in designing and manufacturing the Intelligent Steel Rod Cold Cutting Threading and Flexing Assembly Line, integrating 20+ years of R&D expertise. Our fully automated system combines cutting, threading, and bending into one seamless workflow, delivering precision, energy efficiency, and unmatched reliability.

Why Choose Us?

- ✅ Proven Expertise: Established in 2003 with 37 patents and ISO 9001 certification.

- ✅ End-to-End Solutions: Pre-sales planning, on-site installation, and 24/7 after-sales support.

- ✅ Global Reach: Trusted by clients in 30+ countries across construction, automotive, and energy sectors.

- ✅ Cost Savings: Reduce labor costs by 50% and material waste by 15% with servo-driven automation.

Features & Advantages

✨ All-in-One Automation:

- Feeding, sizing, sawing, threading, bending, and collection completed in one machine.

- ±0.05mm precision with servo-controlled measurement for flawless consistency.

✨ Advanced Cutting & Bending:

- Disc saws enable 30% faster cutting with smooth surfaces.

- Three-axis robots ensure flexible bending (rotation speed: 0–60 RPM).

✨ Smart Design:

- Scrap collection box and three-position bins for organized workflow.

- Optional raw material feeder to minimize manual handling.

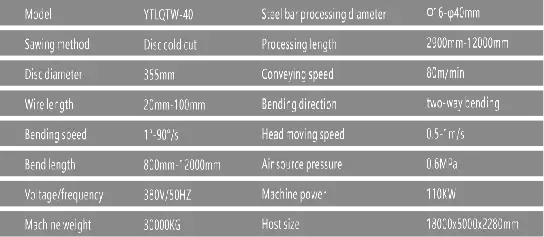

Product Parameters

|

Application Areas

🏗️ Construction: Ideal for bridges and buildings using the Intelligent Steel Rod Cold Cutting Threading and Flexing Assembly Line.

🏢 Prefab Plants: Automates steel rod processing for precast elements with high efficiency.

🚗 Automotive: Used for chassis and suspension rod fabrication with threading and flexing precision.

⚡ Energy Sector: Processes threaded rods for wind turbines and oil infrastructure.

🏭 Metal Fabrication: Custom steel rod cutting and bending for industrial applications.

🔧 Equipment Manufacturing: Supports threaded steel rod parts in machinery and heavy equipment.

🌐 Global Projects: Chosen by exporters needing certified Intelligent Steel rod cold-cutting threading Lines.

Customization Options

Tailor the assembly line to your needs:

- Material Compatibility: Adjust for stainless steel, alloy, or carbon steel.

- IoT Integration: Connect to MES/ERP systems for real-time monitoring.

- Throughput: Scale from 5 to 50 tons/day.

Certifications

- ISO 9001, CE Mark, IATF 16949 (Automotive Standard).

After-Sales Service

🛠️ 24/7 Remote Support: Diagnose issues via video call.

🛠️ On-Site Maintenance: Technicians dispatched within 12 hours (domestic).

🛠️ Spare Parts Guarantee: 10-year supply commitment.

Packaging & Shipping

When it comes to overseas transport, we prioritize the safety of your goods with a two - pronged packaging approach. First, we apply a waterproof wrapping made from high - grade, moisture - resistant materials. This layer acts as a shield against rain, sea spray, and humidity within shipping containers. Over this, we construct sturdy steel - frame crates. The steel frames offer robust structural integrity, capable of withstanding the rough handling that often occurs during international shipping. This combination ensures that your items remain in pristine condition throughout their long - distance journey, whether traveling by sea, air, or land.

About Shaanxi Yongtuo

Founded in 2003, we've steadily ascended to become a preeminent innovator in CNC machinery. Our clientele, including heavyweights like China Railway and BYD Auto, testifies to our reliability and cutting - edge solutions. At our expansive 50,000m² factory in Xi'an, the latest technological marvels are on full display. Robotic welding units work with surgical precision, ensuring each joint is flawless. AI - driven QA systems continuously monitor production, instantly flagging any potential issues. This blend of advanced technology and our commitment to innovation allows us to consistently meet and exceed the high - end demands of our esteemed clients.

FAQ

Q: What's the minimum order quantity?

A: MOQ = 1 unit, with customization available.

Q: Can the machine process curved rods?

A: Yes! Our three-axis robots handle complex bends up to 180°.

Q: How long is the warranty period?

A: 2 years for the entire system.

Q: Do you provide operator training?

A: Yes – 5-day onsite training included.

Q: What's the ROI timeline?

A: Most clients recover costs in 18–24 months via labor savings.

Contact Us

📧 Email: sxyongtuo@gmail.com

Elevate Your Production with the Intelligent Steel Rod Cold Cutting Threading and Flexing Assembly Line

By prioritizing innovation and client success, Shaanxi Yongtuo's Intelligent Steel Rod Cold Cutting Threading and Flexing Assembly Line redefines efficiency for forward-thinking manufacturers. Request a quote today!

YOU MAY LIKE

_1744680888628.png)