2.Servo-controlled fixed-length measurement ensures high accuracy and consistency in cutting.

3.Equipped with a scrap collection bin for centralized collection of leftover materials.

4.Three-position finished product storage bin supports centralized collection of various specifications.

5.The storage bin is equipped with a steel chain for collection, reducing noise during the collection process.

6.Optional automatic raw material feeding system reduces the labor intensity of feeding operations.

7.Optional automatic installation of thread protection caps is available, integrating processes and saving labor costs."

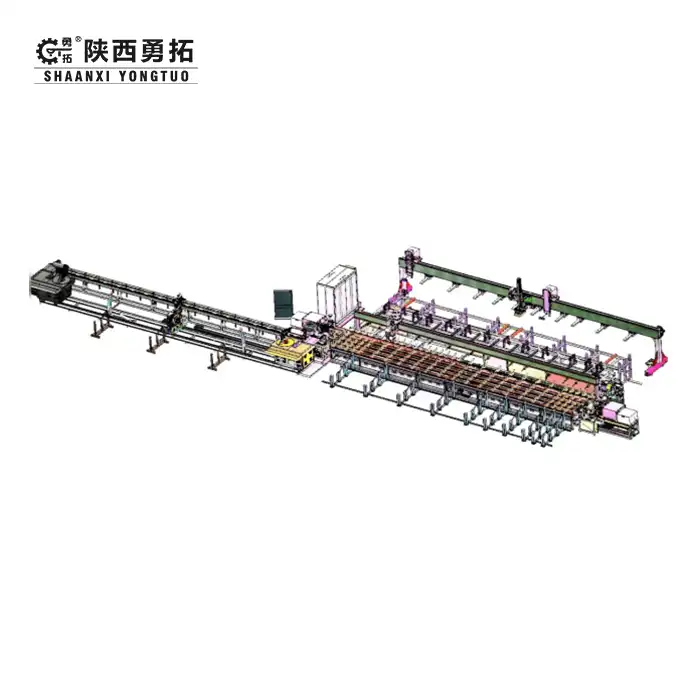

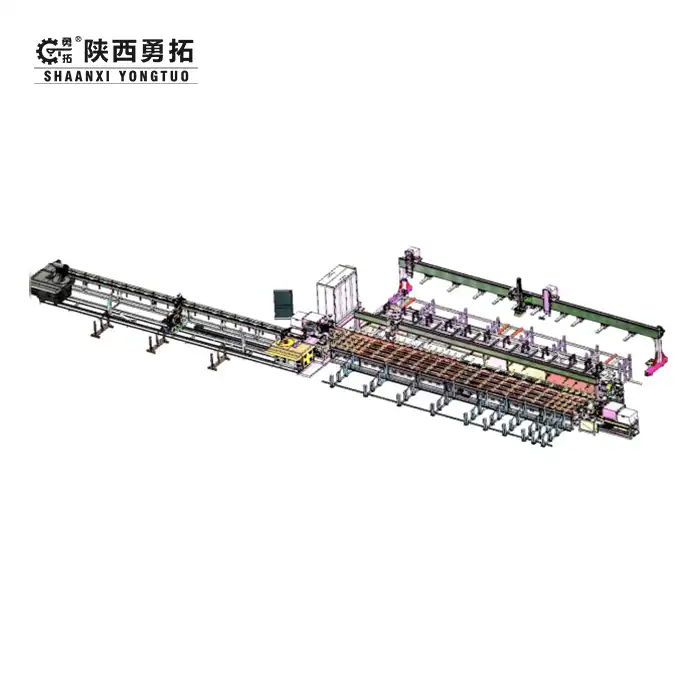

Bar Sawing And Threading Production Line: Precision Redefined

For manufacturers needing bar sawing and threading production line solutions that deliver millimeter accuracy, Shaanxi Yongtuo Machinery combines 20+ years of R&D expertise with robust engineering. Our fully automated systems process round/square steel, stainless steel, and alloy bars (⌀10-50mm) with ≤±0.5mm tolerance.

Why Choose Our Production Line?

- 🇨🇳 37 Patents covering servo measurement & noise reduction

- ⚡ 30% Energy Savings vs. conventional machines

- 🛠️ 5-Year critical component warranty

- 🌍 12-Hour remoteFault diagnosis response

Core Features & Competitive Edge

- Triple-stage scrap collection bins reduce material waste

- CNC touchscreen supports 100+ thread presets (M12-M64)

- Modular design enables automatic feeding or thread cap installation upgrades

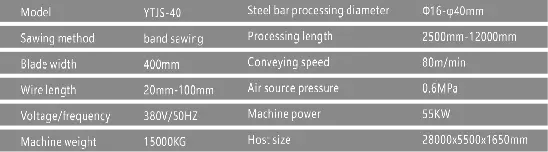

Technical Specifications

Where It Excels: Key Applications

Our equipment is ideal for automotive bolt production, hydraulic cylinder rods, and construction rebar processing. In the case of a Zhejiang client, they witnessed a remarkable jump in Overall Equipment Effectiveness (OEE). After installing our line, their OEE surged from 68% (manual operation) to 92%. This substantial increase not only showcases the efficiency of our solution but also indicates significant potential for other businesses in similar sectors to enhance productivity and profitability.

Tailor Your Configuration

Optional: Laser length verification (+$4,200)

This add - on feature provides pinpoint - accurate length measurements, ensuring consistent product dimensions. Ideal for industries with strict tolerances, it streamlines quality control.

Optional: Coolant - free threading units

These units are an eco - friendly and cost - effective alternative. By eliminating the need for coolant, they reduce maintenance and disposal costs while maintaining high - quality threading performance.

Certifications That Assure Quality

All systems comply with CE Machinery Directive and ISO 9001:2015. These certifications are a testament to our unwavering commitment to quality and safety. By adhering to these international standards, we ensure that our products meet the highest benchmarks in the industry. Download certificates here to verify our compliance and gain confidence in our offerings for your business needs.

After-Sales Package

On - site training (2 days)

Our comprehensive two - day on - site training program is designed to ensure your team can operate our machinery with maximum efficiency. Our experienced trainers will cover all aspects of the equipment, from basic operation to advanced troubleshooting, equipping your staff with the skills they need.

Emergency parts air shipping

In the unfortunate event of a breakdown, time is of the essence. That's why we offer emergency parts air shipping. Our dedicated logistics team will swiftly dispatch the required parts via air freight, minimizing downtime and getting your production back on track as quickly as possible.

FAQ

Q: Minimum order quantity?

A: 1 unit (ready stock), lead time 15 days.

Q: Thread pitch range?

A: 1.0 - 6.0mm, customizable via HMI.

Q: What is the power consumption of the machine?

A: The power consumption varies based on the machine's operation mode, but on average, it is around [X] kW during normal operation, which is designed to be energy - efficient for cost - effective production.

Q: Are there any after - sales services available?

A: Absolutely. We offer a comprehensive after - sales service package including a 1 - year warranty, on - site maintenance within 48 hours in case of major malfunctions, and free technical support for the lifespan of the product.

Q: Can the machine be integrated with existing production lines?

A: Yes, our machine is designed with flexibility in mind. It can be easily integrated into most standard production lines, and our technical team can provide guidance and support for seamless integration.

Bar Sawing And Threading Production Line Experts

Since 2003, we've equipped 1,200+ factories across 30 countries. Schedule a video factory tour: sxyongtuo@gmail.com

YOU MAY LIKE

_1744680888628.png)