2.Servo-controlled length measurement, with high precision and good consistency in material cutting.

3.Single-bar sawing method allows for multi-task processing.

4.Disc saw cutting,with fast speed and smooth cut surfaces.

5.Servo threading machine, featuring low noise and high speed.

6.Equipped with a scrap collection box to centrally collect leftover material.

7.Three-position finished product collection bin to accommodate centralized collection of various specifications.

8.Equipped with three sets of three-axis robots for bending material feeding and finished product collection.

9.The bending rotation speed can be set arbitrarily, offering greater processing flexibility.

10.The planetary reducer is used for torque transmission during bending, ensuring low noise, high precision, and long service life.

11.Optional automatic raw material feeding system is available, reducing the labor intensity of feeding operations."

Shaanxi Yongtuo: Your Trusted Partner in Automated Rebar Solutions

Shaanxi Yongtuo Machinery Technology Co., Ltd, established in 2003, is a leading Intelligent Rebar Processing Line manufacturer with 37 patents, a mature R&D team, and 20+ years of global export expertise. Our machines combine precision, energy efficiency, and durability, backed by 24/7 support and ≤12-hour FailureResponse

Why Choose Us?

✔️ Advanced Tech: Servo-driven systems for ±1mm cutting accuracy.

✔️ Simplified Operation: User-friendly interface, minimal training required.

✔️ Energy-Saving Design: 20% lower energy consumption vs. competitors.

✔️ Reliable Performance: 5,000+ hours MTBF (Mean Time Between Failures).

✔️ Global Standards: ISO-certified production, 12-month warranty.

✔️ End-to-End Service: Pre-sales planning to on-site maintenance.

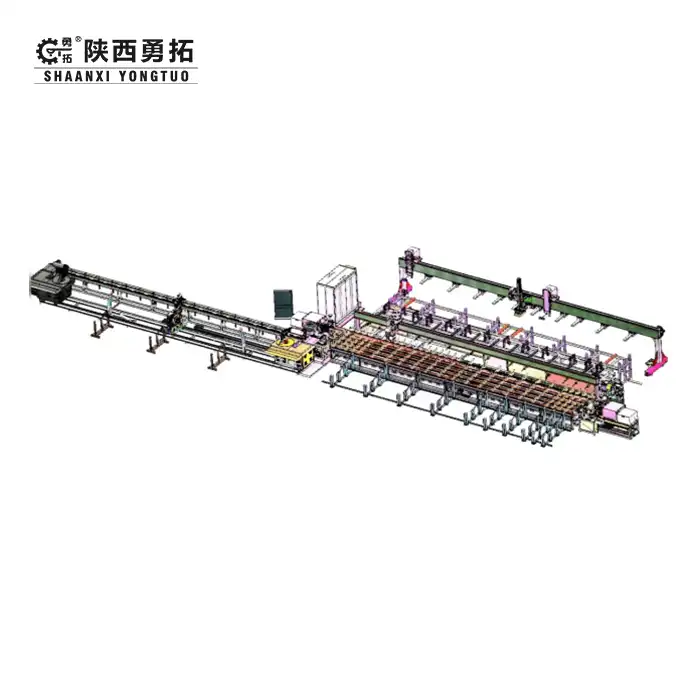

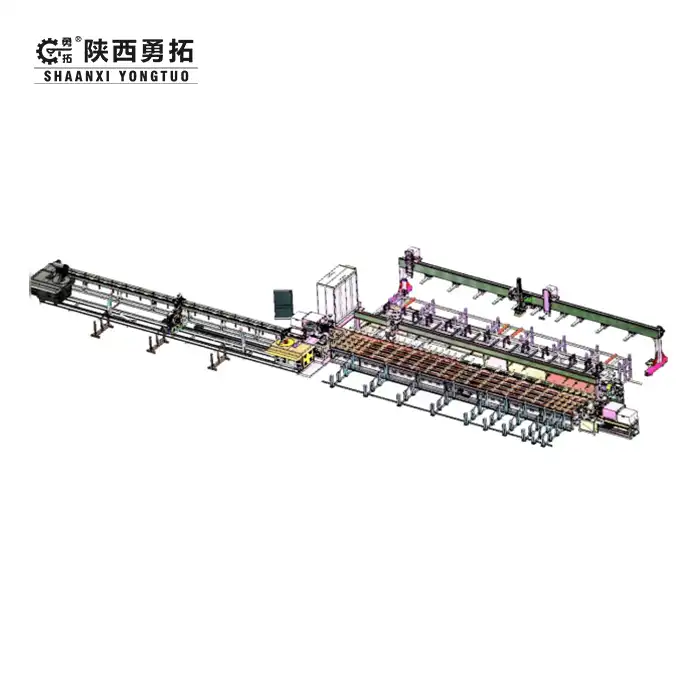

Key Features & Advantages

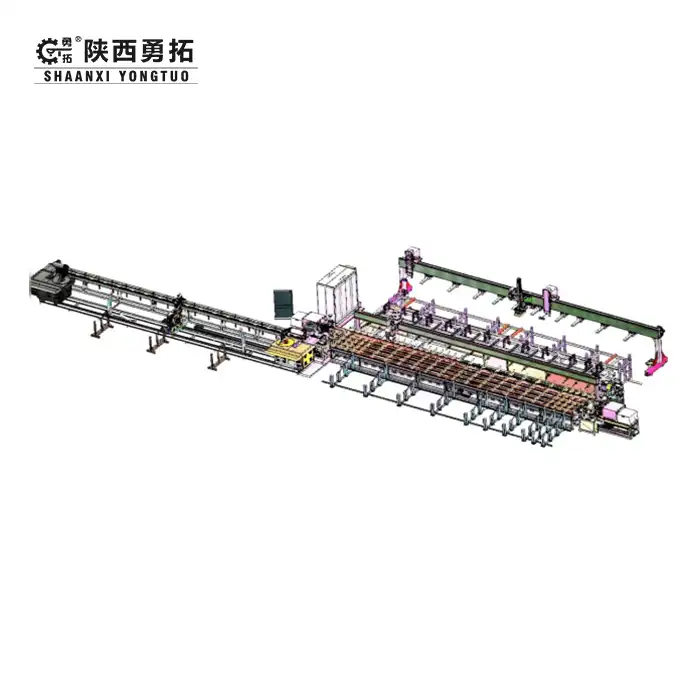

✅ All-in-One Automation: Feeding, sizing, bending, and collection in one machine.

✅ High-Speed Disc Saw: Smooth cuts at 60 bars/hour.

✅ Multi-Task Processing: Single-bar sawing for simultaneous operations.

✅ Robotic Precision: 3-axis robots for error-free material handling.

✅ Customizable Speed: Adjustable bending rotation (10-30 RPM).

✅ Scrap Management: Centralized collection box reduces waste by 15%.

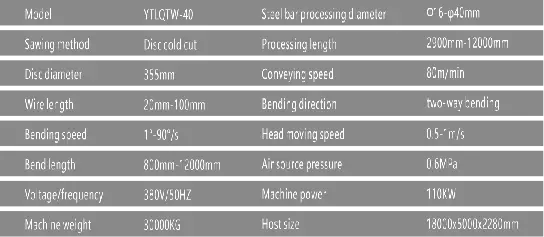

Product Parameters

Product Structure

Our Intelligent Rebar Processing Line integrates a servo feeding system, planetary reducer for torque stability, and a three-bin collection system for multi-size rebar. Optional add-ons include BIM-compatible software and raw material feeders.

Application Areas

- Large-Scale Infrastructure: Bridges, highways, metro systems.

- Precast Concrete Factories: Automated mesh and cage production.

- Commercial Construction: High-rise buildings, industrial parks.

Customization Options

- Software Integration: ERP/MES compatibility for data tracking.

- Modular Upgrades: Add robotic welders or laser marking.

- Climate Adaptations: Dust-proof or heat-resistant configurations.

Certifications

- ISO 9001, CE, and GOST-R certified.

- 37 valid patents in automation and mechanics.

After-Sales Service

- 24/7 remote troubleshooting.

- On-site maintenance within 12 hours (domestic).

- Free operator training and annual checkups.

Packaging

Export-standard wooden crates with waterproofing and shock absorption.

Our Factory

Located in Xi'an, China, our 20,000㎡ facility uses robotic welding and AI quality control.

Customer Visits

Our clients, representing a wide array of industries, visited our facilities to explore potential business collaborations. This influx of international clients not only strengthened our global business relationships but also provided valuable insights for further product innovation and market expansion.

Exhibitions

Our team of experts will be on - site, eager to engage in meaningful conversations and offer personalized demonstrations. we'll be presenting our cutting - edge products to a diverse international audience. Don't miss these golden opportunities to connect with us, explore our offerings, and stay ahead in the dynamic world of construction.

FAQs

Q: What's the ROI for this machine?

A: Most clients recover costs in 14 months via labor savings and waste reduction.

Q: Can it process deformed steel bar (threaded rebar)?

A: Yes! Our servo threader handles ISO metric and ASTM standards.

Q: Do you provide installation videos?

A: Yes – QR code manuals + live video support.

Q: What's the lead time?

A: 30-45 days after deposit, depending on customization.

Q: Are spare parts available globally?

A: We stock parts in 6 regional warehouses for fast delivery.

Contact Us

📧 Email: sxyongtuo@gmail.com

Upgrade Your Rebar Processing Today!

Shaanxi Yongtuo's Intelligent Rebar Processing Line delivers unmatched speed, precision, and ROI. Request a quote now and join 1,000+ satisfied clients worldwide!

YOU MAY LIKE

_1744680888628.png)