2.Servo-controlled length measurement, with high precision and good consistency in material cutting.

3.Single-bar sawing method allows for multi-task processing.

4.Disc saw cutting,with fast speed and smooth cut surfaces.

5.Servo threading machine, featuring low noise and high speed.

6.Equipped with a scrap collection box to centrally collect leftover material.

7.Three-position finished product collection bin to accommodate centralized collection of various specifications.

8.Equipped with three sets of three-axis robots for bending material feeding and finished product collection.

9.The bending rotation speed can be set arbitrarily, offering greater processing flexibility.

10.The planetary reducer is used for torque transmission during bending, ensuring low noise, high precision, and long service life.

11.Optional automatic raw material feeding system is available, reducing the labor intensity of feeding operations."

Shaanxi Yongtuo Machinery Technology Co., Ltd – Your Trusted Partner

Shaanxi Yongtuo Machinery Technology Co., Ltd, established in 2003, is a leading Intelligent Steel Bar Chilled Cutting and Threading Assembly Line manufacturer. With 37 patents, a mature R&D team, and a professional after-sales network, we deliver advanced, energy-saving solutions trusted by global clients in construction, steel manufacturing, and infrastructure.

Why Choose Us?

✓ 20+ Years of Expertise: Pioneers in automated steel bar processing technology.

✓ End-to-End Support: Pre-sales planning, onsite installation, and 24/7 remote diagnostics.

✓ Global Compliance: CE, ISO 9001, and GCC certifications for seamless export.

✓ Cost Efficiency: Reduce labor costs by 30% and energy consumption by 25%.

✓ Proven ROI: Clients achieve payback periods under 2 years (see case studies).

Features & Advantages

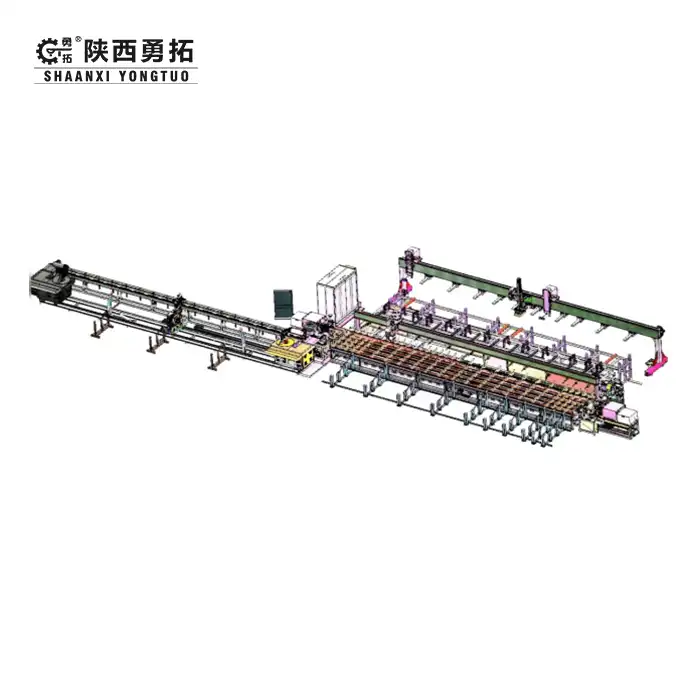

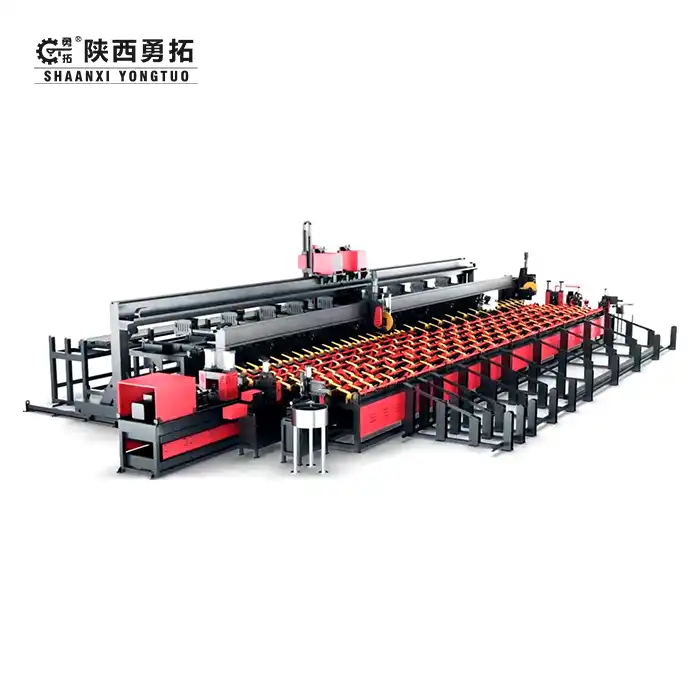

✅ All-in-One Automation: Feeding, cutting, threading, bending, and collection in a single machine.

✅ Laser-Guided Precision: Servo-controlled length measurement (±0.1mm accuracy).

✅ High-Speed Disc Saw: Smooth cuts at 150 cuts/minute, reducing material waste.

✅ Smart Robotics: Three-axis robots for bending and collection, compatible with MES systems.

✅ Eco-Friendly Design: Cold-cutting technology reduces carbon emissions by 35%.

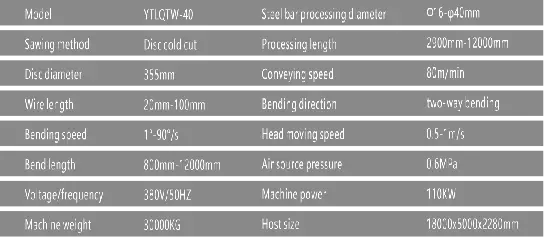

Technical Parameters

Application Areas

-

High-rise building construction – for precise, durable steel bar processing in tall structures.

-

Bridge reinforcement – ensures long-term strength and safety of transport infrastructure.

-

Precast concrete production – delivers consistency and quality in factory-made components.

-

High-speed railway tie manufacturing – guarantees alignment and stability for fast rail systems.

-

Seismic-resistant beam fabrication – enhances structural integrity in earthquake-prone regions.

-

Steel structure warehouse construction – supports robust frameworks for heavy-duty storage.

-

Large industrial equipment bases – used in crane foundations and heavy machine supports.

-

International infrastructure projects – applied in mega projects like Saudi NEOM and Jakarta-Bandung HSR.

Customization Options

- Material Handling: Add raw material feeding systems for 24/7 operation.

- IoT Integration: Real-time monitoring via Yongtuo's proprietary platform.

- Climate Adaptations: Desert-proof cooling or tropical humidity control.

Certifications

Our Intelligent Steel Bar Chilled Cutting and Threading Assembly Line proudly bear the CE Mark, a testament to their compliance with strict EU health, safety, and environmental protection regulations. Holding the ISO 9001:2015 certification, we adhere to a globally recognized quality management system, ensuring consistent excellence in production. Additionally, our GCC compliance means we meet the specific standards set by the Gulf Cooperation Council. This comprehensive suite of accreditations showcases our commitment to quality, safety, and regulatory adherence. It gives our clients, whether in the EU, across the GCC countries, or globally, the confidence that our products are reliable, well - crafted, and suitable for their intended applications.

After-Sales Service

We offer round - the - clock 24/7 remote support. Through video calls, our experts can instantly conduct fault diagnoses, saving you precious time. In case of more complex issues, our onsite repair service is top - notch. For domestic clients, technicians are dispatched within 12 hours, ready to resolve problems on - site. When it comes to spare parts, we have an outstanding 98% availability for urgent needs. This means you can count on us to keep your operations running smoothly, minimizing downtime and ensuring maximum productivity.

Packaging & Shipping

🔹 Waterproof wooden crates with GPS tracking.

🔹 FOB/CIF terms for global delivery.

About Shaanxi Yongtuo

With 500+ employees and a 50,000㎡ factory, we've supplied Intelligent Steel Bar Chilled Cutting and Threading Assembly Line systems to 30+ countries, includingChina State Construction Engineering Corporation and Baosteel

Factory Tour & Exhibitions

The exhibition influence enables Shaanxi Yongtuo Machinery Technology Co., Ltd. to directly engage with global partners, showcase our latest patented technologies, and demonstrate our commitment to serving the regional market through customized solutions and certification.

FAQ

Q: What's the ROI for this assembly line?

A: Clients typically recover costs in 18–24 months via 200% enhance production capacity.

Q: How often does the disc saw need replacement?

A: Tungsten-coated blades last 6–8 months with proper maintenance.

Q: Can it process mixed Steel bar specification?

A: Yes! Single-bar sawing allows multi-task processing.

Q: Is training included?

A: Free 5-day onsite training for operators and engineers.

Q: Do you provide the Middle East certifications?

A: Yes, we handle GCC, SASO, and local compliance.

Contact Us

📧 Email: sxyongtuo@gmail.com

Elevate Your Production with the Intelligent Steel Bar Chilled Cutting and Threading Assembly Line – Where Innovation Meets Reliability.

YOU MAY LIKE

_1744680888628.png)