2.Servo-controlled fixed-length measurement ensures high accuracy and consistency in cutting.

3.Equipped with a scrap collection bin for centralized collection of leftover materials.

4.Three-position finished product storage bin supports centralized collection of various specifications.

5.The storage bin is equipped with a steel chain for collection, reducing noise during the collection process.

6.Optional automatic raw material feeding system reduces the labor intensity of feeding operations.

7.Optional automatic installation of thread protection caps is available, integrating processes and saving labor costs."

Shaanxi Yongtuo: Your Trusted Rod Shearing and Bending Work Platform Partner

Shaanxi Yongtuo Machinery Technology Co., Ltd, established in 2003, specializes in manufacturing Rod Shearing and Bending Work Platforms with 20+ years of expertise. Our advanced CNC technology, energy-saving designs, and ISO-certified processes ensure reliable, high-performance equipment tailored for construction, metalworking, and heavy industries.

Why Choose Us?

- ✅ Advanced R&D: 37 patents and a mature engineering team drive innovation.

- ✅ Export-Ready: Over a decade of global delivery experience.

- ✅ End-to-End Support: Pre-sales planning, onsite training, and ≤12-hour response.

- ✅ Cost Efficiency: Energy-saving operation reduces TCO (total cost of ownership).

- ✅ Quality Assurance: Rigorous testing ensures compliance with CE and ISO standards.

Features & Advantages

- Servo-Controlled Precision: ±1mm cutting accuracy for consistent results.

- Scrap Collection Bin: Centralizes waste, improving worksite safety.

- 3-Station Storage: Organizes multiple rebar specifications effortlessly.

- Noise Reduction: Steel chain-equipped bins minimize operational噪音.

- Optional Automation: Add feeding systems or thread cap installers to boost productivity.

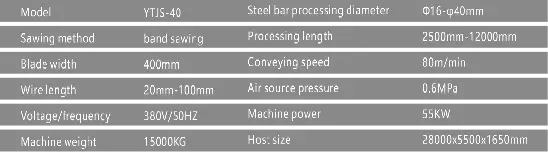

Product Parameters

Detailed demonstration

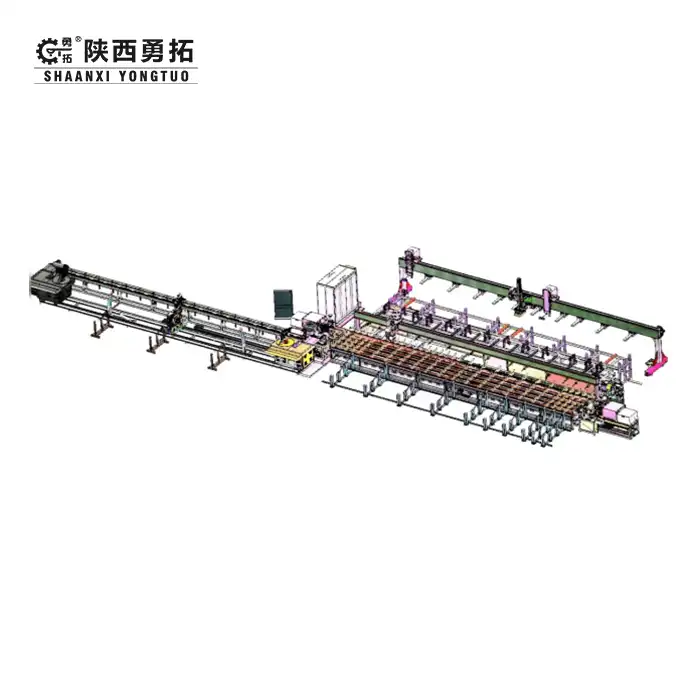

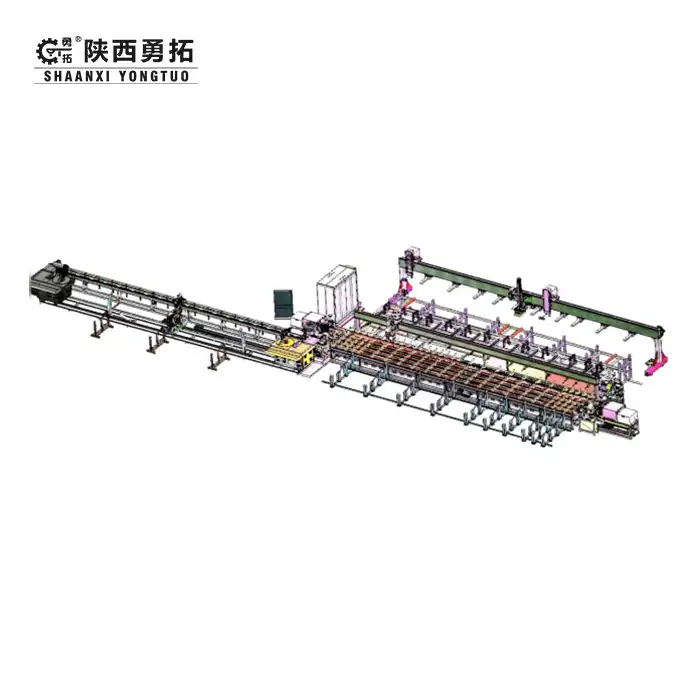

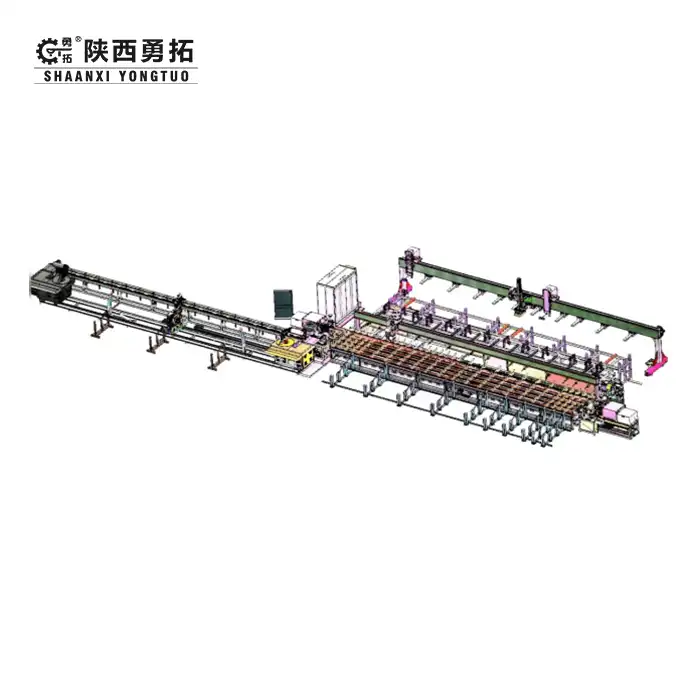

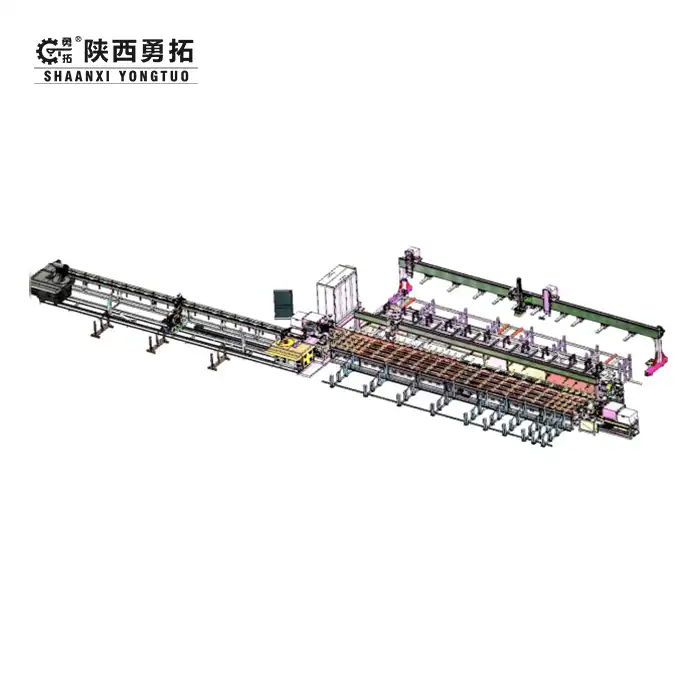

Our Rod Shearing and Bending Work Platform integrates feeding, measurement, sawing, threading, and collection into one seamless system. The servo-driven fixed-length cutter guarantees accuracy, while modular components allow quick adjustments for diverse projects.

Application Areas

- Construction: Bridges, high-rise steel frameworks.

- Manufacturing: Automotive chassis, shipbuilding components.

- Energy: Wind turbine bases, transmission towers.

- Infrastructure: Railways, highway guardrails.

Customization Options

Tailor your platform with:

- IoT-enabled performance monitoring.

- Hydraulic/pneumatic bending modes.

- Multi-language interfaces.

Certifications

- ISO 9001, CE, OSHA compliance.

- RoHS-certified components.

After-Sales Service

- 24/7 remote troubleshooting.

- Onsite maintenance within 12 hours (domestic).

- Lifetime technical support.

Packaging

Our export - standard wooden crates are engineered to the highest quality levels. They feature advanced waterproofing measures, such as a special sealant applied to all wooden surfaces, which prevents moisture ingress during long - distance ocean or air shipments. Inside, high - density shock - absorbing materials like polyurethane foam are strategically placed. This foam cushions the items, protecting them from vibrations and impacts that can occur during handling and transportation, ensuring your valuable goods arrive in perfect condition.

Company Introduction

Founded in 2003, Shaanxi Yongtuo has long been a paragon of combining innovation with practicality. Our dedicated 200+ team, comprising engineers, technicians, and support staff, harnesses their collective expertise. They've been hard at work serving clients in 50+ countries. By leveraging state - of - the - art technology and years of industry experience, we consistently deliver robust metal processing solutions. These solutions not only meet but often exceed the expectations of our global clientele, ensuring seamless metal fabrication for various industrial applications.

Our Factory

Located in Xi'an, our 20,000m² facility is a technological marvel. Our CNC machining centers, equipped with advanced software, churn out precision - engineered parts with remarkable accuracy. The automated assembly lines then seamlessly bring these components together. This setup not only boosts production efficiency but also ensures consistent product quality. With a skilled workforce overseeing the operations, we're well - positioned to meet the diverse manufacturing needs of industries ranging from automotive to aerospace.

Customer Visits

Clients from Germany, UAE, and Australia have praised our Rod Shearing and Bending Work Platform for its durability and ROI.

Exhibitions

Our expert team will be there to guide you through the live demonstrations, highlighting the unique features and benefits of our products. Whether it's our high - performance excavators or state - of - the - art concrete mixers, you can expect an immersive experience that will give you a clear understanding of how our offerings can enhance your projects. Don't miss this golden opportunity to engage with us, explore potential partnerships, and stay ahead in the highly competitive construction industry.

FAQs

Q: Can it process stainless steel?

A: Yes, with upgraded blades (optional).

Q: What's the warranty period?

A: 2 years for core components.

Q: Do you provide installation training?

A: Free onsite training included.

Q: How to reduce noise further?

A: Add soundproof enclosures (customizable).

Q: Can I order a single unit?

A: Yes! MOQ = 1.

Contact Us for Your product!

📧 Email: sxyongtuo@gmail.com

📍 Address: Gaoxin Road, Xi'an, Shaanxi, China

Optimize your metal fabrication workflow with Shaanxi Yongtuo's Rod Shearing and Bending Work Platform—where precision meets productivity.

YOU MAY LIKE

_1744680888628.png)