2.Servo-controlled length measurement, with high precision and good consistency in material cutting.

3.Single-bar sawing method allows for multi-task processing.

4.Disc saw cutting, with fast speed and smooth cut surfaces.

5.Servo threading machine, featuring low noise and high speed.

6.Equipped with a scrap collection box to centrally collect leftover material.

7.Three-position finished product collection bin to accommodate centralized collection of various specifications.

8.The collection bin is equipped with a steel chain for collection, reducing noise during collection.

9.Optional automatic raw material loading device to reduce the labor intensity of loading work.

10.Optional automatic installation device for thread protectors, streamlining processes and saving labor."

Shaanxi Yongtuo Machinery Technology Co., Ltd – Your Trusted Partner

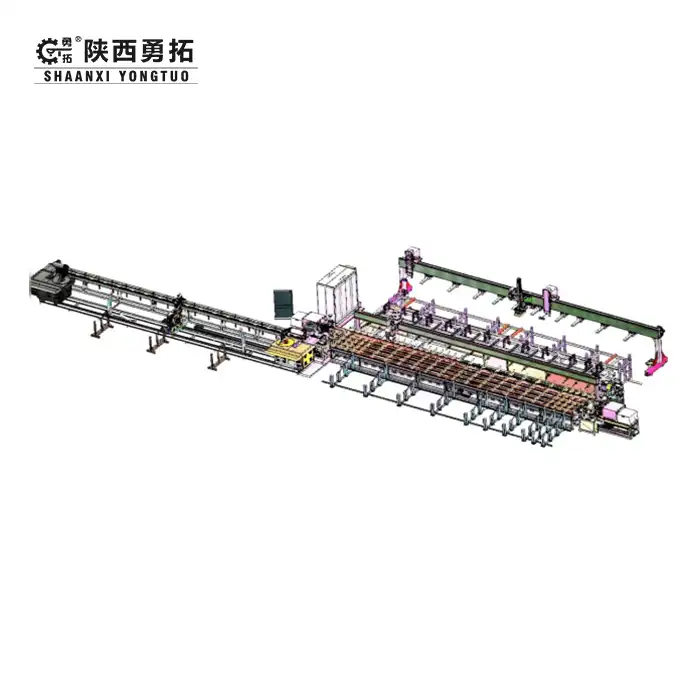

As a leading Intelligent Cold Cutting And Threading Production Line manufacturer and supplier, Shaanxi Yongtuo Machinery combines 20+ years of expertise with advanced servo-controlled automation. Our factory-direct solutions deliver unmatched precision in rebar processing, backed by ISO 9001 certification and 37 patented technologies.

Why Choose Us?

✅ Mature R&D Team – Continuous innovation since 2003.

✅ Global Export Experience – Trusted by clients in 30+ countries.

✅ Energy-Saving Design – Reduce operational costs by 20%.

✅ 24/7 After-Sales Support – ≤12-hour response for urgent repairs.

✅ End-to-End Customization – Tailor solutions for oil, gas, construction, and automotive needs.

Key Features & Advantages

- High-Precision Servo Measurement – ±0.1mm accuracy for API-standard threading.

- Disc Saw Cutting – Smooth, burr-free finishes at 120 cuts/minute.

- Multi-Task Processing – Single-bar sawing handles threading, milling, and cutting.

- Noise-Reduced Collection – Chain-driven bins minimize operational disruption.

- IoT-Ready Integration – Monitor performance via PLC or MES systems.

Technical Parameters

Application Areas

- Oil & Gas: API-certified pipe threading for drilling and pipelines.

- Construction: Automated rebar processing for bridges and high-rises.

- Automotive: High-speed bolt and axle production.

- Aerospace: Titanium alloy component machining.

Customization Options

- Auto Raw Material Loader – Reduce manual handling.

- Thread Protector Installation – Add robotic arms for seamless assembly.

- Extended Collection Bins – Adapt for large-scale projects.

Certifications

- ISO 9001, CE, API Q1.

- Compliant with OSHA and EU Machinery Directive.

After-Sales Service

- 24/7 Remote Diagnostics – Instant troubleshooting via video call.

- On-Site Maintenance – Domestic technicians dispatched within 12 hours.

- 5-Year Warranty – Covering motors, PLCs, and servo systems.

Packaging & Shipping

Waterproof wooden crates with shock - absorbent foam are designed to provide top - notch protection for your valuable cargo. The wooden crates are carefully treated with a waterproof sealant, guarding against any moisture during transit, whether by sea or air. Inside, high - density shock - absorbent foam cushions items, minimizing the risk of damage from bumps and jolts. Additionally, we support both FCL (Full Container Load) and LCL (Less - than - Container Load) global shipping options. This flexibility allows you to choose the most cost - effective and suitable shipping method based on the size and quantity of your goods, ensuring seamless transportation to destinations all around the world.

About Shaanxi Yongtuo

Join 500+ global clients who've toured our Xi'an facility. When you visit, you'll be greeted by our knowledgeable team and get an up - close look at our advanced manufacturing processes. During live demos, witness firsthand how our cutting - edge technology works to produce high - quality products. Engage in in - depth discussions about ROI optimization, where we'll share strategies and insights based on our extensive experience. Learn how our solutions can enhance your productivity, reduce costs, and ultimately boost your return on investment, just like we've done for our numerous satisfied clients worldwide.

FAQ

Q: Can this Intelligent Cold Cutting And Threading Production Line process stainless steel?

A: Yes! It handles Φ12–40mm stainless, alloy, and carbon steel.

Q: What's the lead time for customization?

A: 60–90 days, including design and testing.

Q: Do you provide installation training?

A: Yes – free on-site training for 5+ operators.

Q: What payment terms are accepted?

A: T/T, LC, or installment plans.

Q: How to request a quote?

A: Email specs to 13892319900@sxyongtuo.com for a 24-hour response.

Visit Us!

During live demos, witness firsthand how our cutting - edge technology works to produce high - quality products. Engage in in - depth discussions about ROI optimization, where we'll share strategies and insights based on our extensive experience. Learn how our solutions can enhance your productivity, reduce costs, and ultimately boost your return on investment, just like we've done for our numerous satisfied clients worldwide.

Ready to Upgrade Your Production Line?

Contact Shaanxi Yongtuo for your Intelligent Cold Cutting And Threading Production Line today!

YOU MAY LIKE

_1744680888628.png)