2.Servo-controlled fixed-length measurement ensures high accuracy and consistency in cutting.

3.Equipped with a scrap collection bin for centralized collection of leftover materials.

4.Three-position finished product storage bin supports centralized collection of various specifications.

5.The storage bin is equipped with a steel chain for collection, reducing noise during the collection process.

6.Optional automatic raw material feeding system reduces the labor intensity of feeding operations.

7.Optional automatic installation of thread protection caps is available, integrating processes and saving labor costs."

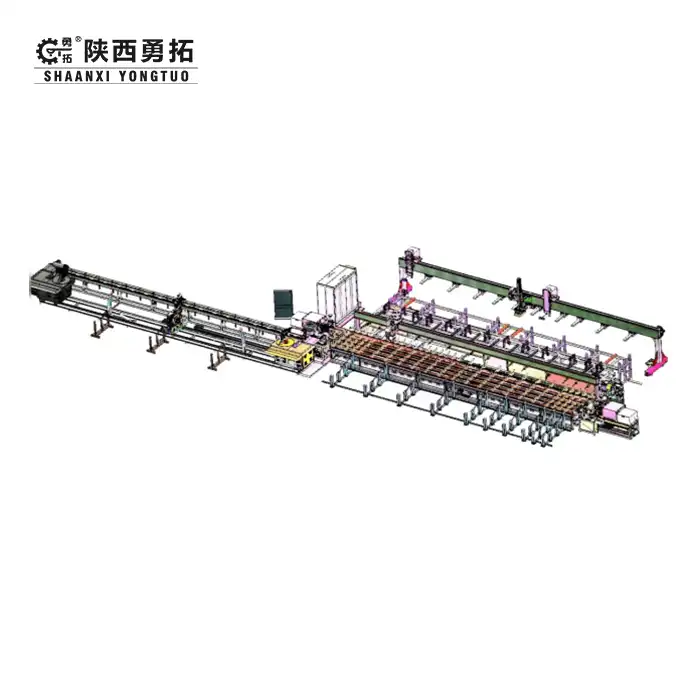

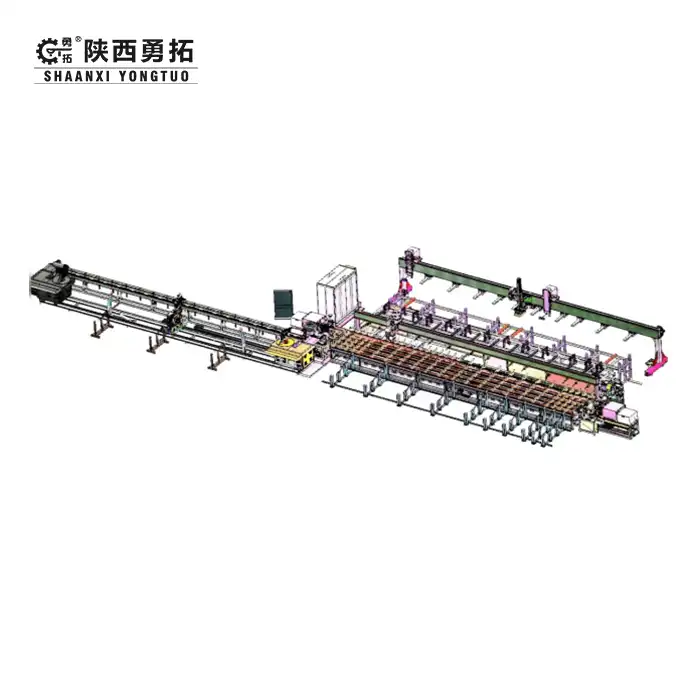

Why Choose Shaanxi Yongtuo's Rod Sawing and Threading Manufacturing Line?

Shaanxi Yongtuo Machinery Technology Co., Ltd, established in 2003, is a leading Rod Sawing and Threading Manufacturing Line manufacturer with 37 patents, a mature R&D team, and over 20 years of global export experience. Our equipment combines advanced CNC technology, energy-saving designs, and standardized services to deliver unmatched reliability.

Why Choose Us?

- ✅ Expertise: 20+ years in bar processing machinery R&D and production.

- ✅ Quality Assurance: ISO-certified manufacturing with CE compliance.

- ✅ Custom Solutions: Tailor-made designs for unique material or specification needs.

- ✅ 24/7 Support: ≤12-hour fault response and lifetime technical guidance.

- ✅ Cost Efficiency: Reduce labor costs by 50% with automation options.

Key Features & Advantages

- Precision Cutting: Servo-controlled fixed-length measurement ensures ±0.5mm accuracy.

- Automation Ready: Optional auto-feeding and thread cap installation systems.

- Noise Reduction: Steel chain-equipped storage bins for quieter operations.

- Waste Management: Centralized scrap collection minimizes material loss.

- Multi-Spec Handling: Three-position bins support diverse rod diameters (Φ12-Φ50mm).

- Energy Saving: 15% lower power consumption vs. traditional models.

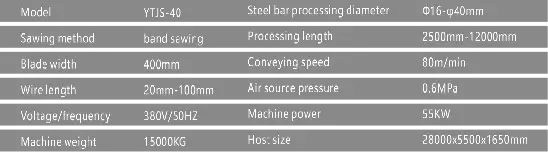

Technical Parameters

Application Areas

Ideal for industries requiring high-precision rod processing:

- Construction: Rebar threading for steel structures.

- Automotive: Engine bolts, transmission components.

- Oil & Gas: Drill pipes, valve parts.

- Aerospace: Titanium alloy fasteners.

- Power Equipment: Transformer connectors.

Custom Options

Adjust speed, storage capacity, or add IoT monitoring. Tailor our products precisely to your operational needs. Whether you require a faster Rod Sawing and Threading Manufacturing Line rate, enhanced storage capabilities for larger volumes, or real - time IoT monitoring to optimize performance, we've got you covered.

Certifications

CE, ISO 9001, and SGS compliance. These certifications are a testament to our unwavering commitment to quality, safety, and international standards. By adhering to CE, ISO 9001, and SGS requirements, you can trust that our offerings meet the highest benchmarks in the industry, giving you confidence in your purchase.

After-Sales Service

- 24/7 remote diagnosis.

- Free operator training.

- 2-year warranty + lifetime spare parts supply.

Packaging & Delivery

Waterproof wooden crates with shock - absorbent foam. Our packaging solution is designed to safeguard your valuable items during transit. The wooden crates are treated with a special waterproof coating, protecting against moisture from rain or high - humidity environments. Inside, thick layers of shock - absorbent foam cushion your products, minimizing the risk of damage from bumps and jolts. For global shipping, we partner with industry leaders DHL and FedEx. Their extensive networks ensure that your packages reach destinations worldwide in a timely and reliable manner, providing you peace of mind throughout the shipping process.

Company & Factory

Founded in 2003, our 12,000㎡ Xi'an factory is a hub of advanced manufacturing capabilities. We seamlessly integrate CNC machining, where precision - engineered components are crafted with micron - level accuracy. The assembly area efficiently brings these parts together, following strict quality protocols. Our dedicated testing labs are equipped with state - of - the - art equipment to rigorously evaluate the performance and durability of every product. This integrated setup ensures that from raw material to finished goods, each item leaving our factory meets the highest standards of quality and functionality, ready to serve diverse industries both locally and globally.

FAQ

Q: Can this line process stainless steel?

A: Yes! It handles stainless steel, alloy steel, and titanium.

Q: What's the lead time?

A: 30-45 days after deposit.

Q: Do you provide installation?

A: Free remote guidance; on-site service available.

Q: How to reduce noise further?

A: Add our soundproof enclosure (optional).

Q: Warranty coverage?

A: Covers all mechanical parts for 24 months.

Boost Your Productivity Today! ✉️

Contact our experts atsxyongtuo@gmail.com for a free layout design and quote.

Shaanxi Yongtuo Machinery Technology Co., Ltd

Innovating Rod Sawing and Threading Manufacturing Lines Since 2003

YOU MAY LIKE

_1744680888628.png)