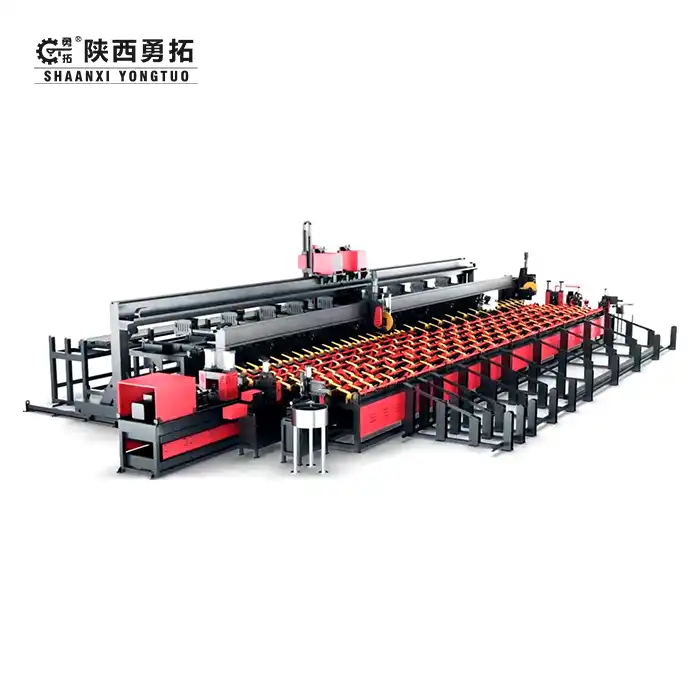

2.Servo-controlled length measurement, with high precision and good consistency in material cutting.

3.Single-bar sawing method allows for multi-task processing.

4.Disc saw cutting,with fast speed and smooth cut surfaces.

5.Servo threading machine, featuring low noise and high speed.

6.Equipped with a scrap collection box to centrally collect leftover material.

7.Three-position finished product collection bin to accommodate centralized collection of various specifications.

8.Equipped with three sets of three-axis robots for bending material feeding and finished product collection.

9.The bending rotation speed can be set arbitrarily, offering greater processing flexibility.

10.The planetary reducer is used for torque transmission during bending, ensuring low noise, high precision, and long service life.

11.Optional automatic raw material feeding system is available, reducing the labor intensity of feeding operations."

Shaanxi Yongtuo Machinery Technology Co., Ltd: Your Trusted Partner

Shaanxi Yongtuo Machinery Technology Co., Ltd, established in 2003, is a leading Intelligent Steel Rod Fabrication and Flexing Line manufacturer with 37 patents, a 20-year export legacy, and a dedicated R&D team. Our machines combine advanced automation, energy efficiency, and unmatched reliability for industries ranging from construction to aerospace.

Why Choose Our Intelligent Steel Rod Fabrication and Flexing Line?

✅ Proven Expertise: 20+ years in steel bar processing equipment design.

✅ Full Automation: Feeding, cutting, bending, and collection in one machine.

✅ Global Compliance: CE and ISO 9001 certified, meeting international standards.

✅ 24/7 Support: On-site maintenance ≤12 hours (domestic) and remote diagnostics.

✅ Cost Efficiency: Reduce labor costs by 40% with servo-driven precision.

Key Features & Advantages

✨ All-in-One Processing: Automate sizing, threading, and bending with zero manual intervention.

✨ Servo Precision: ±0.1mm cutting accuracy for automotive-grade consistency.

✨ Multi-Task Sawing: Single-bar processing with disc-saw technology for smooth cuts.

✨ Robotic Collection: Three-axis robots ensure seamless material handling.

✨ Energy Savings: 25% lower power consumption vs. traditional machines.

✨ IoT-Ready: Monitor production data in real time for smart factory integration.

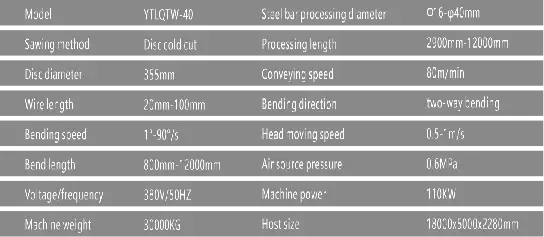

Technical Specifications

Application Areas

🏗️ Construction: High-rise buildings, bridges, and tunnels.

🚗 Automotive: Chassis and frame components.

🔧 Metalworking: Custom industrial parts.

🌍 Energy: Wind turbine towers, oil pipelines.

🚀 Aerospace: High-strength, lightweight materials.

Customization Options

Tailor your Intelligent Steel Rod Fabrication and Flexing Line with:

- Automatic raw material feeders.

- Custom bending angles (0°-180°).

- Multi-language control interfaces.

Certifications

🔹 CE Marked

🔹 ISO 9001:2015

🔹 GB/T 19001-2016

After-Sales Service

- 24/7 remote troubleshooting.

- ≤12-hour on-site response (China).

- Lifetime technical guidance.

Packaging

For safe global shipping, we utilize waterproof wooden crates that are meticulously designed to protect your valuable items. The wooden exteriors are treated to be completely waterproof, warding off moisture from rain, humidity, or any water - related risks during transit. Inside, a thick layer of shock - absorbent foam is carefully installed. This foam cushions your cargo, minimizing the impact of jolts, bumps, and vibrations that can occur during loading, unloading, and transportation on various terrains and through different modes of transport. Whether your shipment is traveling by sea, air, or land across the globe, our packaging solution ensures your items reach their destination in perfect condition, providing you with peace of mind throughout the shipping process.

About Shaanxi Yongtuo

Our success story is built on the strength of our 300+ dedicated employees and the efficiency of our 20,000㎡ factory. This workforce, a blend of skilled technicians, innovative engineers, and astute managers, collaborates seamlessly to drive production.

FAQ

Q: Can this machine handle stainless steel rods?

A: Yes! It processes carbon steel, stainless steel, and alloy rods up to Φ40mm.

Q: How long is the warranty period?

A: 3-year warranty on critical components.

Q: Is operator training included?

A: Free onsite training for all buyers.

Q: What's the lead time?

A: 30-60 days, depending on customization.

Q: Do you provide spare parts?

A: Yes – we stock 500+ parts for fast delivery.

Contact Us Today!

Transform your production with Shaanxi Yongtuo's Intelligent Steel Rod Fabrication and Flexing Line – where innovation meets reliability.

YOU MAY LIKE

_1744680888628.png)