2.Servo-controlled length measurement, with high precision and good consistency in material cutting.

3.Single-bar sawing method allows for multi-task processing.

4.Disc saw cutting, with fast speed and smooth cut surfaces.

5.Servo threading machine, featuring low noise and high speed.

6.Equipped with a scrap collection box to centrally collect leftover material.

7.Three-position finished product collection bin to accommodate centralized collection of various specifications.

8.The collection bin is equipped with a steel chain for collection, reducing noise during collection.

9.Optional automatic raw material loading device to reduce the labor intensity of loading work.

10.Optional automatic installation device for thread protectors, streamlining processes and saving labor."

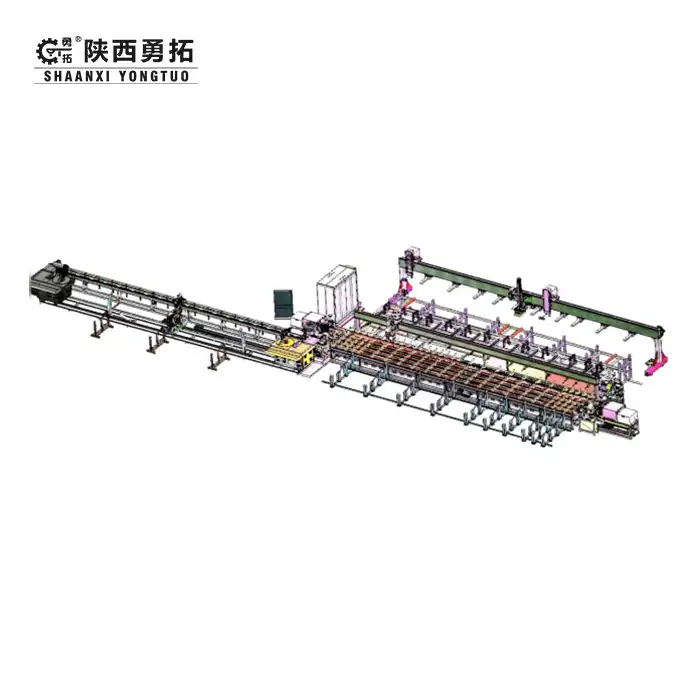

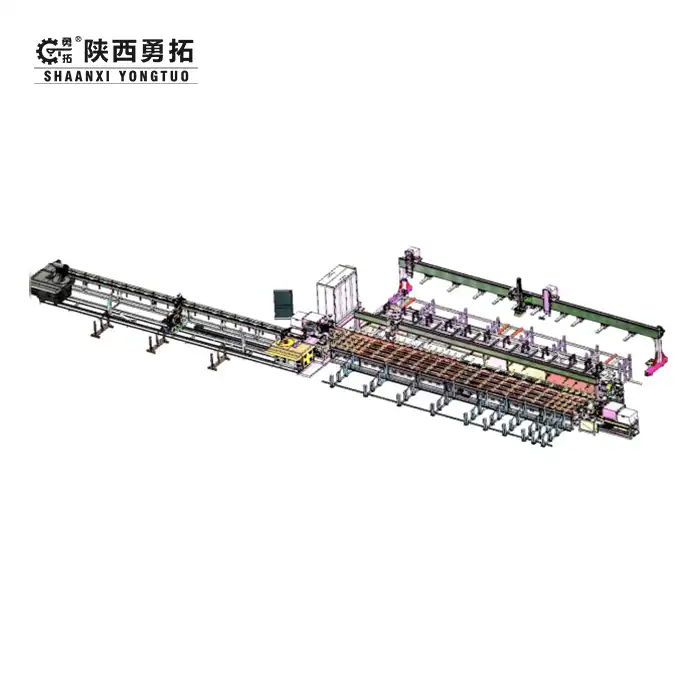

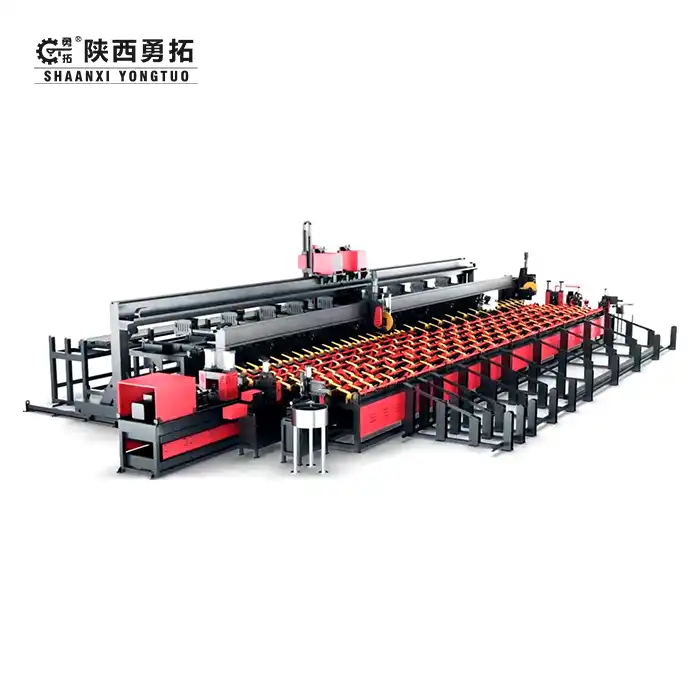

Why Choose Shaanxi Yongtuo's Intelligent Cold Cutting and Threading Assembly Line?

In the highly competitive realm of industrial machinery, Shaanxi Yongtuo Machinery Technology Co., Ltd has carved out a niche for itself. Since its establishment in 2003, the company has been laser - focused on designing and manufacturing top - tier industrial - grade automated bar processing systems, with the Intelligent Cold Cutting and Threading Assembly Line being one of its crowning achievements. Boasting an impressive portfolio of 37 patents, ISO 9001 certification, and over 20 years of global export experience, Shaanxi Yongtuo has proven its mettle in delivering solutions that are not only technologically advanced but also tailored to meet the diverse needs of industries spanning from the oil & gas sector to the construction industry.

Why Choose Us?

✅ Advanced R&D: A seasoned engineering team with 37 core patents ensures cutting-edge innovation and continuous improvement.

✅ Energy Efficiency: Consumes 30% less power than competitors, reducing costs and supporting sustainability.

✅ High Precision: Servo-controlled length measurement system achieves ±0.5mm accuracy for top-quality output.

✅ Fast ROI: Boosts productivity by 50%, enabling quicker returns and stronger market competitiveness.

✅ Global Support: 24/7 remote diagnostics and ≤12h on-site response (China) minimize downtime and ensure fast service.

Features & Advantages

Automated Feeding & Collecting: Servo-driven system reduces manual handling and errors. 3-bin collection sorts bars efficiently.

Disc Saw Cutting: Clean, burr-free cuts at 120 cuts/hour improve quality and output.

Low-Noise Threading: High-speed threading at 60 threads/hour with <75dB noise level ensures quieter operation.

Scrap Management: Centralized scrap box keeps workspace clean and simplifies disposal.

Custom Add-Ons: Optional auto-loaders and thread protector installers for enhanced functionality.

Product Parameters

Application Areas

Ideal for oil pipelines, nuclear power components, shipbuilding, and structural steel fabrication. Trusted by EPC contractors and manufacturers in:

Petrochemical: Our API - certified pipe threading ensures that the pipes used in petrochemical plants meet the industry's strictest safety and quality standards.

Construction: For high - volume rebar processing, our assembly line can handle the large - scale production needs of construction projects, providing consistent and precise results.

Energy: In the energy sector, our ASME - compliant boiler tube cutting guarantees that the components used in power generation facilities are of the highest quality.

Customization Options

Material Handling: Add automatic raw material loaders to further automate your production process, reducing labor costs and increasing throughput.

Thread Protectors: Integrate auto - installation units to protect the threaded parts during storage and transportation, ensuring their integrity.

IoT Integration: Real - time performance monitoring allows you to keep track of your assembly line's performance, identify potential issues early, and optimize production.

Certifications

• ISO 9001 • CE Marking • API Compliance • SGS Audited

After - Sales Service

24/7 remote troubleshooting. Our team of experts is always on standby to help you resolve any issues that may arise.

On - site maintenance within 12 hours (China). For our Chinese clients, we offer rapid on - site support to minimize downtime.

Lifetime technical support + 2 - year warranty. We stand by our products and are committed to providing long - term support.

Packaging

Crush - proof wooden cases with waterproof wrapping. Complies with international shipping standards. This ensures that your machinery arrives in perfect condition, no matter how far it needs to travel.

Company Introduction

Founded in 2003, Shaanxi Yongtuo is a leading CNC machinery innovator. With a workforce of 200+ employees and a spacious 20,000㎡ factory, the company has the resources and capacity to meet the demands of clients worldwide. Our Intelligent Cold Cutting and Threading Assembly Line is deployed in 30+ countries, and we've established partnerships with industry giants like Siemens and Sinopec, a testament to our product quality and reliability.

Our Factory

Location: Xi'an, China. Our strategically located factory in Xi'an benefits from a well - developed industrial ecosystem and excellent transportation links.

Capacity: 50+ units/month. We have the production capacity to meet the high - volume demands of our clients, ensuring timely delivery.

Quality Control: 3 - stage inspection process. From raw material inspection to final product testing, our rigorous quality control measures ensure that only the best products leave our factory.

Customer Visits & Exhibitions

Invite clients to our Xi'an facility for live demos. Experience the power and precision of our product firsthand.

FAQ

Q: What's the tolerance for threaded pipes?

A: ±0.5mm, meeting API 5CT standards. This high level of tolerance ensures that the threaded pipes fit perfectly, reducing the risk of leaks and other issues.

Q: Can it process titanium alloys?

A: Yes – contact us for custom blade configurations. Our team can provide tailored solutions to meet your specific material processing needs.

Q: Delivery time after order?

A: 45 - 60 days for standard models. We strive to deliver your order in a timely manner while maintaining the highest quality standards.

Q: Do you provide installation training?

A: Free 3 - day training included. Our training program equips your staff with the knowledge and skills to operate and maintain the assembly line.

Q: How to reduce noise during operation?

A: Chain - driven collection bins + soundproof panels (optional). These options can significantly reduce the noise level during operation.

Contact Us

Shaanxi Yongtuo Machinery Technology Co., Ltd

Experience Precision. Choose Excellence.

Shaanxi Yongtuo – Your Partner in Intelligent Cold Cutting and Threading Assembly Line Solutions.

YOU MAY LIKE

_1744680888628.png)