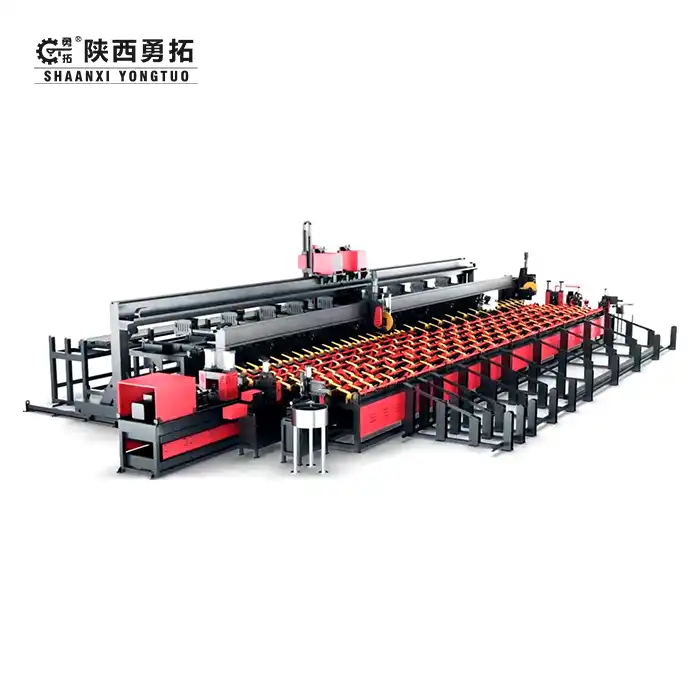

2.Servo-controlled length measurement, with high precision and good consistency in material cutting.

3.Single-bar sawing method allows for multi-task processing.

4.Disc saw cutting,with fast speed and smooth cut surfaces.

5.Servo threading machine, featuring low noise and high speed.

6.Equipped with a scrap collection box to centrally collect leftover material.

7.Three-position finished product collection bin to accommodate centralized collection of various specifications.

8.Equipped with three sets of three-axis robots for bending material feeding and finished product collection.

9.The bending rotation speed can be set arbitrarily, offering greater processing flexibility.

10.The planetary reducer is used for torque transmission during bending, ensuring low noise, high precision, and long service life.

11.Optional automatic raw material feeding system is available, reducing the labor intensity of feeding operations."

Shaanxi Yongtuo: Your Trusted Manufacturer & Supplier

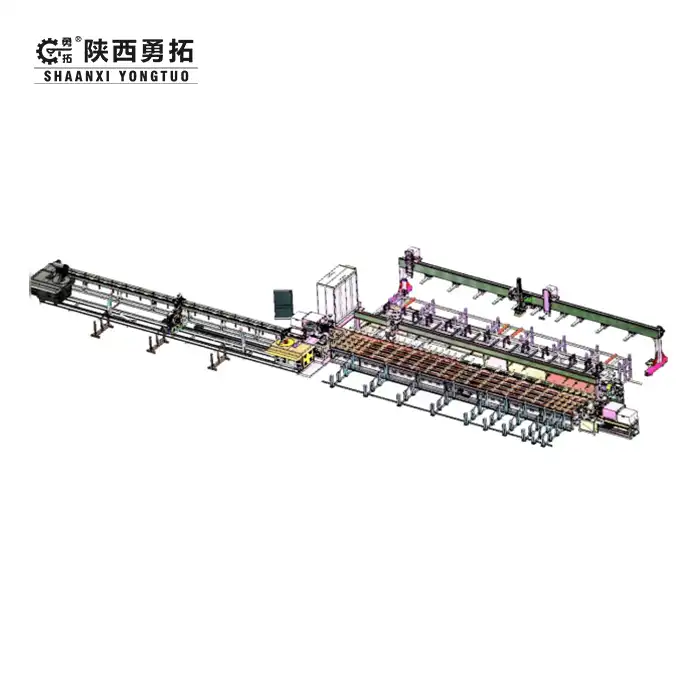

Shaanxi Yongtuo Machinery Technology Co., Ltd, established in 2003, is a leading Intelligent Steel Bar Cold Cutting And Threading Bending Production Line manufacturer. With 37 patents, a mature R&D team, and 20+ years of export experience, we deliver advanced, energy-saving solutions backed by 24/7 global after-sales support.

Why Choose Us?

- ✅ Advanced Technology: Servo-driven precision cutting, bending, and threading systems.

- ✅ Simplified Operation: Intuitive interface for minimal training.

- ✅ Energy Efficiency: 30% lower power consumption vs. competitors.

- ✅ Reliable Performance: Planetary reducers and disc saws ensure <0.1mm error.

- ✅ Standardized Service: ≤12-hour fault response, pre-sales planning, and onsite support.

- ✅ Proven Quality: CE-certified, trusted by 500+ global clients.

Features & Advantages

- 🔹 All-in-One Automation: Feeding, cutting, threading, bending, and collection in one machine.

- 🔹 Servo-Controlled Precision: ±0.5mm length accuracy for zero material waste.

- 🔹 Multi-Task Processing: Single-bar sawing handles diverse specifications simultaneously.

- 🔹 High-Speed Cutting: Disc saws deliver 60 cuts/hour with smooth surfaces.

- 🔹 Low-Noise Threading: Servo-driven system reduces noise by 40%.

- 🔹 Smart Collection: Scrap boxes and 3-bin sorting for efficient workflow.

- 🔹 Robotic Flexibility: Three-axis robots enable complex bending tasks.

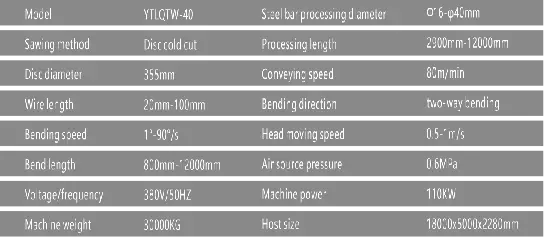

Product Parameters

|

Application Areas

The Intelligent Steel Bar Cold Cutting and Threading Bending Production Line by Shaanxi Yongtuo is engineered for high-efficiency processing of reinforcement steel bars in demanding industrial environments. Its precision, automation, and durability make it an ideal solution for:

🏗️ Construction & Infrastructure

Used in high-rise buildings, bridges, tunnels, and highways for producing stirrups, anchor rods, and threaded rebar with ±0.5mm accuracy.

🏭 Precast Concrete Plants

Perfect for automated production of prefabricated components such as beams, columns, and cage assemblies—streamlining steel bar preparation before casting.

🚇 Metro & Rail Projects

Supports the fabrication of reinforced track slabs, diaphragm walls, and metro tunnel linings with consistent thread quality and bending accuracy.

🌍 Overseas Engineering Projects

Trusted by global contractors working under ISO/CE standards on airports, ports, and industrial parks across Asia, Europe, and the Middle East.

Customization Options

- Software upgrades for MES/ERP integration.

- Adjustable bending angles (0°–180°).

- Optional raw material feeding systems.

Certifications

✔️ ISO 9001, CE, and SGS certifications.

After-Sales Service

- 24/7 remote diagnostics.

- Onsite maintenance within 12 hours (China).

- Lifetime technical support.

Packaging

Waterproof wooden crates with shockproof foam.

Factory Tour

Visit our sprawling 20,000m² Xi'an facility, a beacon of modern manufacturing. Here, state - of - the - art CNC machining centers hum with precision, churning out intricate components with micron - level accuracy. Automated assembly lines seamlessly integrate these parts, streamlining production and minimizing human error. As you tour, you'll witness the harmonious dance of technology and efficiency. Our knowledgeable staff will be on hand to explain the processes, showing you how our facility sets the standard for high - quality, large - scale production in the industry.

Exhibitions

Engage in direct conversations with our experts, who can answer all your queries and provide insights into how our machinery can enhance your construction projects.

FAQs

Q1: What is the lead time for standard and customized machines?

A: Standard models ship within 30–45 days; custom configurations may require up to 60 days.

Q2: Can your system handle stainless steel or special alloys?

A: Yes, with tailored tooling and adjustable speed/power settings, our machines process stainless steel, rebar, and composite materials with ease.

Q3: How much labor can your automation save?

A: Our integrated robotic system reduces manual labor by up to 60%, typically replacing 2–3 workers per shift.

Q4: Is operator training provided?

A: Absolutely. We offer free 5-day onsite training, along with a complete user manual and remote video support.

Q5: What warranty and support do you offer?

A: A 2-year warranty covers all critical components. We provide lifetime technical support, remote diagnostics, and 72-hour global spare parts delivery.

Contact Us

📧 Email: sxyongtuo@gmail.com

Upgrade to Yongtuo's Intelligent Steel Bar Cold Cutting And Threading Bending Production Line—precision engineered for your large-scale projects. Request a Quote Today!

YOU MAY LIKE

_1744680888628.png)