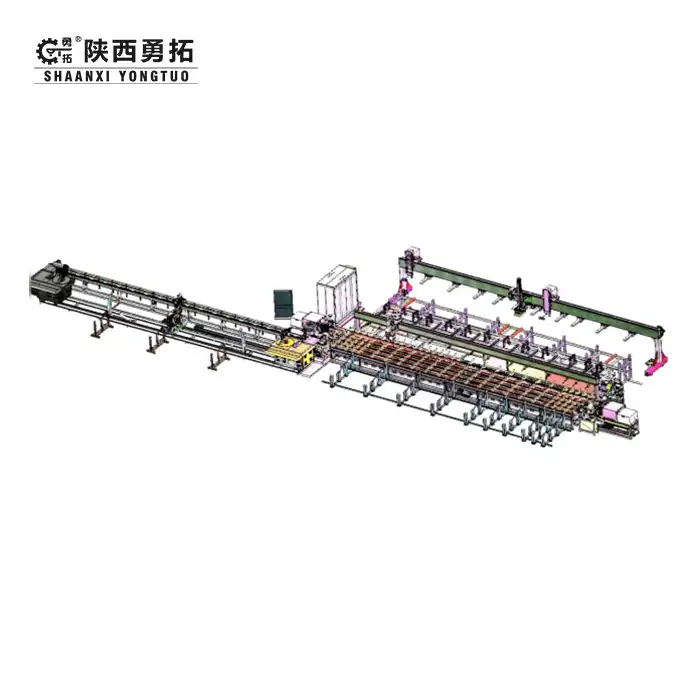

2.Servo-controlled length measurement, with high precision and good consistency in material cutting.

3.Single-bar sawing method allows for multi-task processing.

4.Disc saw cutting,with fast speed and smooth cut surfaces.

5.Servo threading machine, featuring low noise and high speed.

6.Equipped with a scrap collection box to centrally collect leftover material.

7.Three-position finished product collection bin to accommodate centralized collection of various specifications.

8.Equipped with three sets of three-axis robots for bending material feeding and finished product collection.

9.The bending rotation speed can be set arbitrarily, offering greater processing flexibility.

10.The planetary reducer is used for torque transmission during bending, ensuring low noise, high precision, and long service life.

11.Optional automatic raw material feeding system is available, reducing the labor intensity of feeding operations."

Shaanxi Yongtuo: Your Trusted Smart Steel Rod Processing Partner

Shaanxi Yongtuo Machinery Technology Co., Ltd, established in 2003, specializes in manufacturing Smart Steel Rod Processing Assembly Lines that redefine efficiency for steel fabrication. With 37 patents, a mature R&D team, and 20+ years of global expertise, we deliver energy-saving, high-precision solutions trusted by automotive, construction, and infrastructure industries.

Why Choose Us?

✅ Expert R&D Team: Innovating since 2003, with 37 core patents.

✅ Full-Cycle Support: Pre-sales planning, real-time technical guidance, and ≤12-hour故障 response.

✅ Global Compliance: CE, ISO 9001, and GB/T-certified systems.

✅ Cost Efficiency: Reduce labor costs by 40% and scrap rates to ≤1%.

✅ Proven Track Record: Trusted by clients in 30+ countries.

Features & Advantages

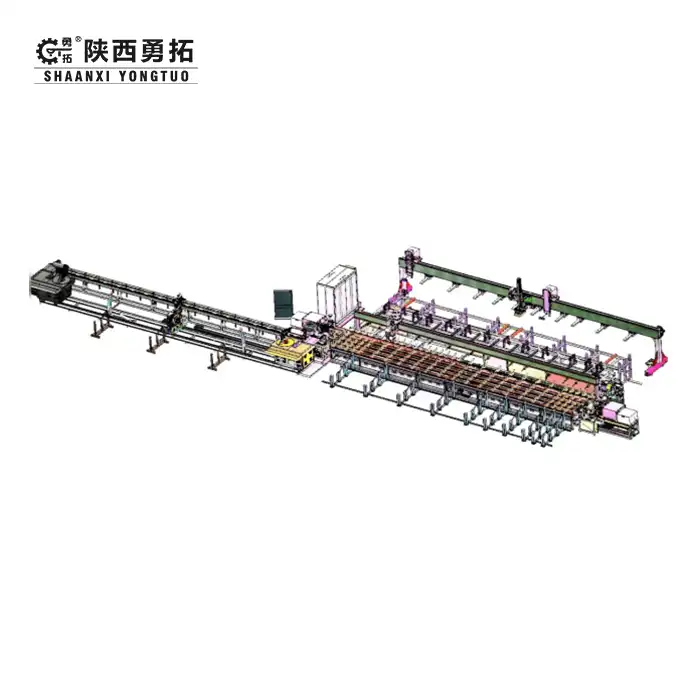

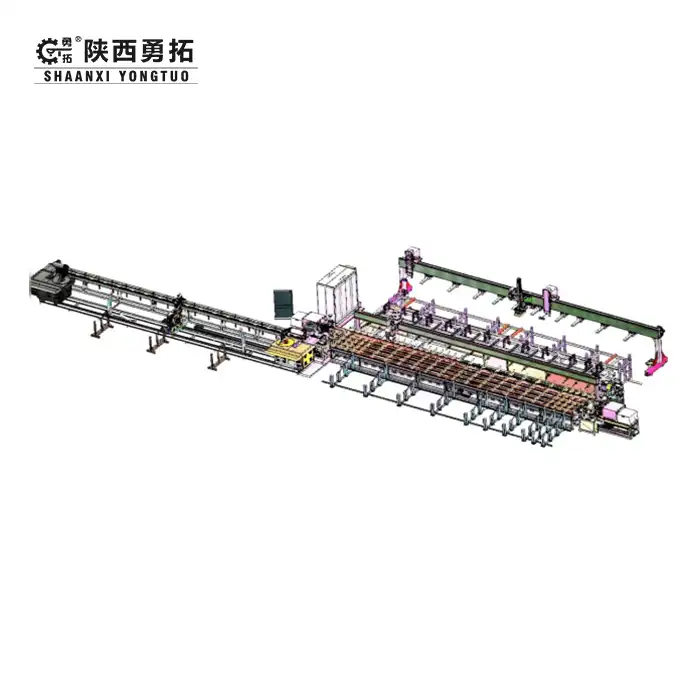

- All-in-One Automation: Feeding, cutting, threading, bending, and collection in a single product.

- Servo Precision: ±0.1mm cutting accuracy with disc-saw technology.

- Multi-Task Flexibility: Single-bar sawing for simultaneous operations.

- IoT-Ready: Optional data integration for predictive maintenance.

- Energy Savings: 30% lower power consumption vs. traditional systems.

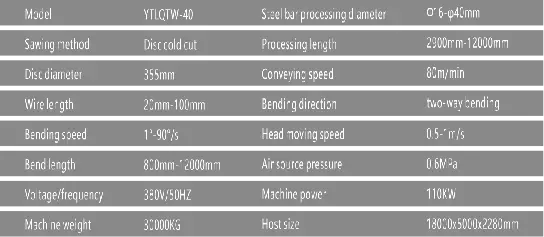

Product Parameters

Product Structure

Our Smart Steel Rod Processing Assembly Line integrates:

- Servo Feeding System: Ensures consistent material alignment.

- AI-Powered Vision Inspection: Detects defects in real-time.

- Three-Axis Robots: Automate bending and sorting tasks.

- Scrap Collection Hub: Centralizes waste for recycling.

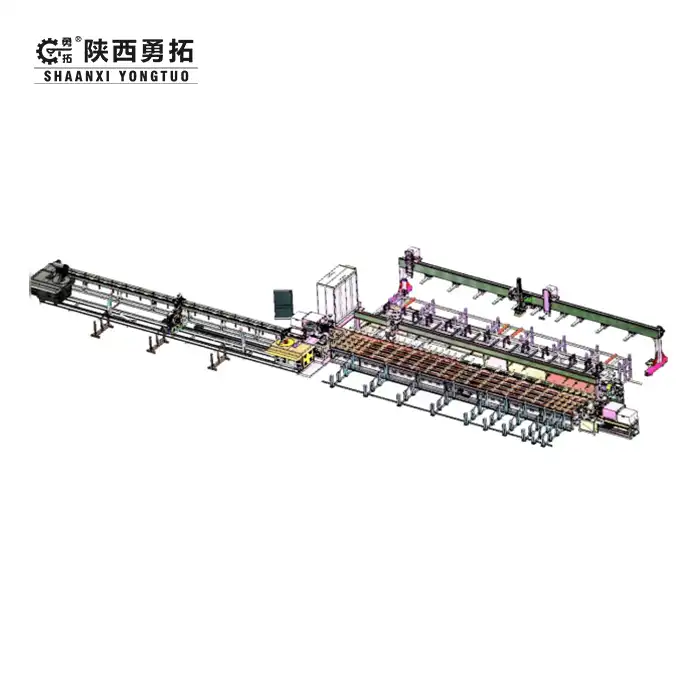

Application Areas

- Construction: High-speed production of rebar for bridges, tunnels, and high-rises.

- Automotive: Precision shafts and transmission components.

- Energy: Custom steel rods for wind turbine towers.

- Railways: Compliant with GB/T 1499.2-2018 standards.

Customization Options

- Material Compatibility: Adaptable to stainless steel, alloy rods, etc.

- IoT Integration: Connect to ERP/MES for data-driven optimization.

- Feeding Systems: Upgrade to automated raw material loaders.

Certifications

- ISO 9001:2015

- CE Marking

- China Compulsory Certification (CCC)

After-Sales Service

- 24/7 remote diagnostics.

- On-site support within 12 hours (domestic).

- Lifetime technical consultations.

Packaging

Weatherproof wooden crates with anti-rust coatings for safe global shipping.

Company Introduction

Founded in 2003, Shaanxi Yongtuo is a pioneer in intelligent steel processing systems, serving clients across Asia, Africa, and Europe.

Our Factory

Located in the vibrant city of Xi'an, our expansive 20,000㎡ facility is a hub of advanced manufacturing. State - of - the - art CNC machining centers take center stage, capable of producing components with micron - level precision. These centers are staffed by highly skilled technicians who ensure seamless operation. Adjacent to the machining area, our automated testing labs are equipped with cutting - edge instruments. Here, every product undergoes rigorous quality checks, from performance evaluations to durability tests. This combination of top - tier machining and comprehensive testing capabilities allows us to deliver products of the highest standard, meeting the diverse needs of our clients across various industries.

Customer Visits

🤝 Shaanxi Yongtuo warmly welcomes global partners to visit our Xi'an facility, explore intelligent solutions firsthand, and discuss long-term cooperation.

Exhibitions

Shaanxi Yongtuo Machinery Technology Co., Ltd. actively participates in major global trade fairs to showcase our Intelligent Steel Rod Cold Cutting Threading and Flexing Assembly Line. These events allow us to connect with industry leaders, explore market trends, and present our latest automation technologies to clients worldwide.

FAQs

Q1: Can this line handle non-standard rod shapes?

A: Yes! We customize tooling for hexagonal, flat, or irregular profiles.

Q2: What's the ROI timeline?

A: Most clients achieve breakeven within 18–24 months via labor savings.

Q3: Is training included?

A: Free on-site training for operators and technicians.

Q4: How to handle power fluctuations?

A: Built-in voltage stabilizers ensure consistent performance.

Q5: Do you support retrofitting older systems?

A: Absolutely—upgrade legacy equipment with our IoT modules.

Contact Us

Ready to transform your steel processing? Let's discuss your project!

📧 Email: sxyongtuo@gmail.com

Why Settle for Less?

Choose the Smart Steel Rod Processing Assembly Line by Shaanxi Yongtuo—where innovation meets reliability.

YOU MAY LIKE

_1744680888628.png)