2.Servo-controlled length measurement, with high precision and good consistency in material cutting.

3.Single-bar sawing method allows for multi-task processing.

4.Disc saw cutting,with fast speed and smooth cut surfaces.

5.Servo threading machine, featuring low noise and high speed.

6.Equipped with a scrap collection box to centrally collect leftover material.

7.Three-position finished product collection bin to accommodate centralized collection of various specifications.

8.Equipped with three sets of three-axis robots for bending material feeding and finished product collection.

9.The bending rotation speed can be set arbitrarily, offering greater processing flexibility.

10.The planetary reducer is used for torque transmission during bending, ensuring low noise, high precision, and long service life.

11.Optional automatic raw material feeding system is available, reducing the labor intensity of feeding operations."

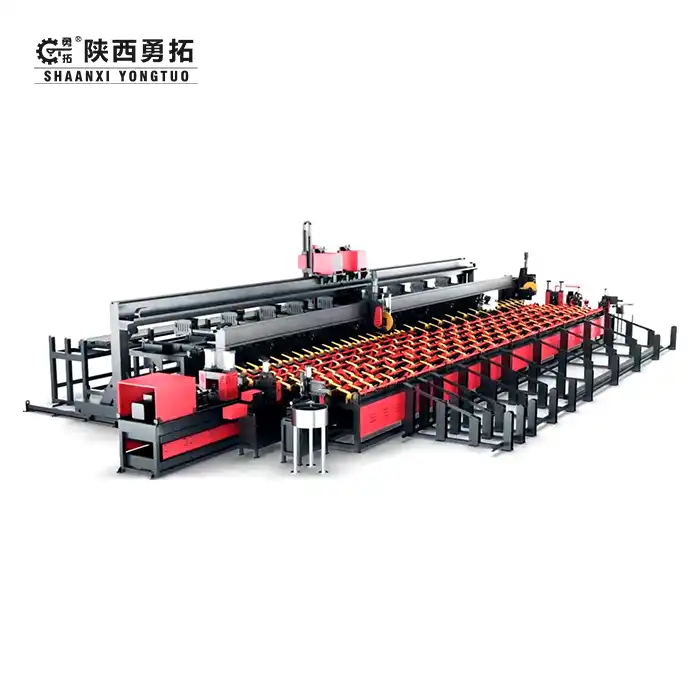

Shaanxi Yongtuo: Your Trusted Partner

Shaanxi Yongtuo Machinery Technology Co., Ltd, established in 2003, specializes in designing Intelligent Cutting Flexing and Hooking Production Systems that integrate 37 patented technologies. With 20+ years of expertise, we deliver automated, energy-efficient solutions trusted by global manufacturers in automotive, aerospace, and medical industries.

Why Choose Us?

✅ Advanced R&D: 37 patents ensure cutting-edge innovation.

✅ End-to-End Service: Pre-sales planning to 24/7 after-sales support.

✅ Export-Ready: ISO-certified systems with 10+ years of global delivery.

✅ Cost Efficiency: Reduce material waste by 30% and labor costs by 50%.

✅ Proven Reliability: 2,000+ operational units worldwide.

Features & Advantages

✨ All-in-One Automation: Feeding, sizing, bending, and collection in a single machine.

✨ Precision Cutting: Servo-controlled length measurement (±0.1mm accuracy).

✨ Multi-Task Processing: Single-bar sawing handles complex orders.

✨ Energy Savings: 20% lower power consumption vs. competitors.

✨ Durable Design: Planetary reducers ensure 10,000+ hours of maintenance-free operation.

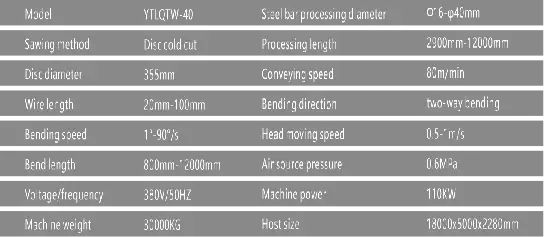

Technical Parameters

Application Areas

- Automotive: Seat frame bending, airbag thread cutting.

- Aerospace: Carbon fiber component shaping.

- Medical: Surgical tool hooks, biodegradable suture preparation.

- Electronics: Flexible PCB trimming.

- Smart Home: Curved sofa frame fabrication.

Customization Options

- Material Adaptation: Configure for titanium, memory foam, or Kevlar.

- Software Integration: Compatible with Siemens PLCs and MES systems.

- Feeding Systems: Add robotic arms or conveyor belts.

Certifications

🔹 ISO 9001:2015 🔹 CE Marking 🔹 RoHS Compliance

After-Sales Service

- 24/7 Remote Support: ≤12-hour on-site response (China).

- Lifetime Upgrades: Free software updates.

- Spare Parts Guarantee: 72-hour global delivery.

Packaging & Delivery

🌍 Our shockproof wooden crates are designed to safeguard your precious cargo during even the most challenging transports. The crates are constructed with thick, resilient wood and filled with high - density shock - absorbing materials to cushion against impacts. Equipped with GPS tracking, you can monitor the exact location of your shipment in real - time, whether it's traversing the vast oceans via sea freight or hurtling through the skies with air freight options. This combination of secure packaging and advanced tracking technology offers unparalleled peace of mind, ensuring your items reach their destination intact and on - schedule, no matter where in the world they're bound.

Company Introduction

Founded in 2003, Shaanxi Yongtuo has emerged as a global leader, catering to clients in 50+ countries with our state - of - the - art Intelligent Cutting, Flexing and Hooking Production Systems. Our sprawling 200 - acre factory in Xi'an is a marvel of modern manufacturing. Here, AI - driven production processes optimize efficiency, enabling us to churn out high - quality products at scale. Complementing this, our rigorous quality control (QC) procedures ensure that every unit leaving our facility meets the highest international standards, making us a trusted partner for businesses worldwide.

Factory Tour

🔧 Smart Workshop: 15 CNC machining centers, robotic assembly lines.

🔧 Quality Lab: 3D scanning, tensile testing.

Exhibitions

We regularly participate in leading international exhibitions to showcase our latest technologies and connect with partners around the world. These events provide valuable opportunities for live Intelligent Cutting Flexing and Hooking Production System demonstrations, technical consultations, and face-to-face engagement with our team.

FAQs

Q: What's the lead time?

A: 30–45 days for standard models; 60 days for custom builds.

Q: Can it process carbon fiber?

A: Yes! Configure blade hardness and cutting speed via our HMI.

Q: How much floor space is needed?

A: Compact design: 6.5m x 2.2m.

Q: ROI timeframe?

A: 8–14 months via labor/material savings.

Q: Training included?

A: Free 5-day onsite training + 200-page manual.

Contact Us

📧 Email: sxyongtuo@gmail.com

Upgrade Your Production Line with the Intelligent Cutting Flexing and Hooking Production System Today!

YOU MAY LIKE

_1744680888628.png)