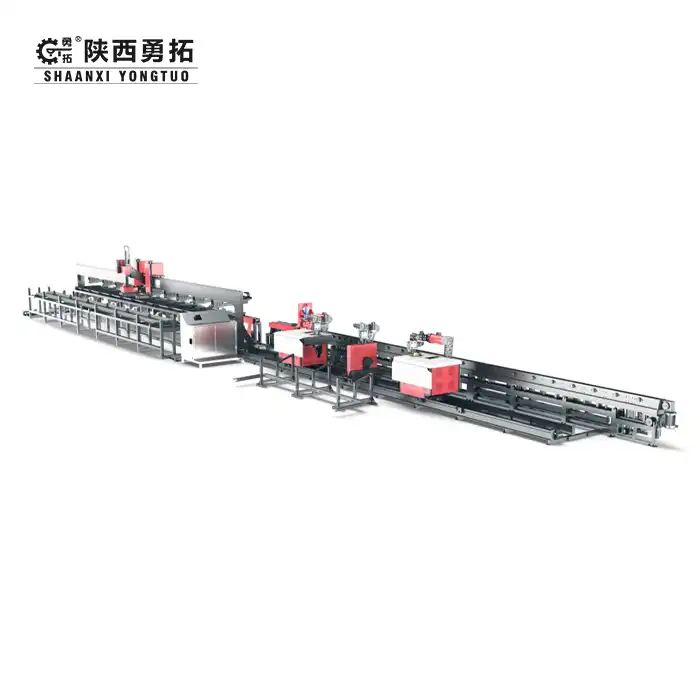

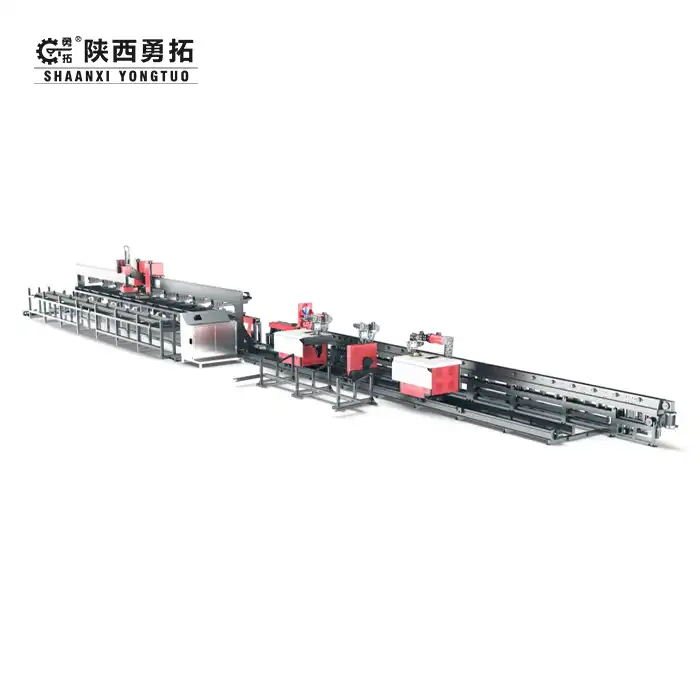

2.Bending rotation speed is adjustable, providing high processing flexibility.

3.Equipped with three sets of three-axis robotic arms for bending material feeding.

4.Equipped with two sets of three-axis robotic arms for finished product collection.

5.Separate execution of bending feeding and finished product collection increases production efficiency.

6.Multi-station finished product storage bins allow simultaneous collection of products of various specifications.

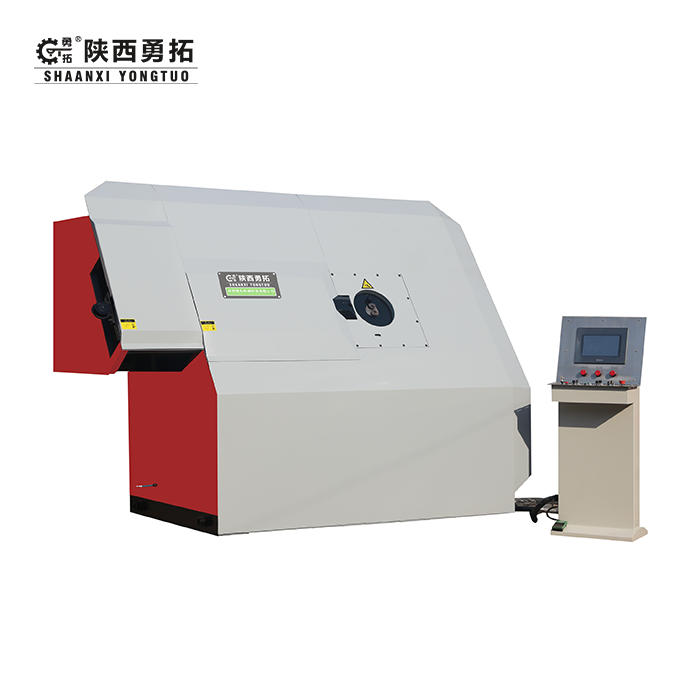

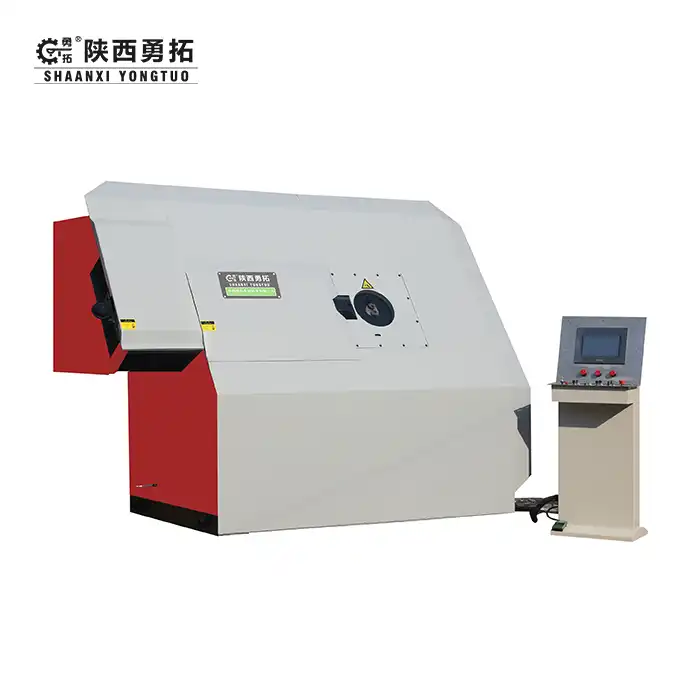

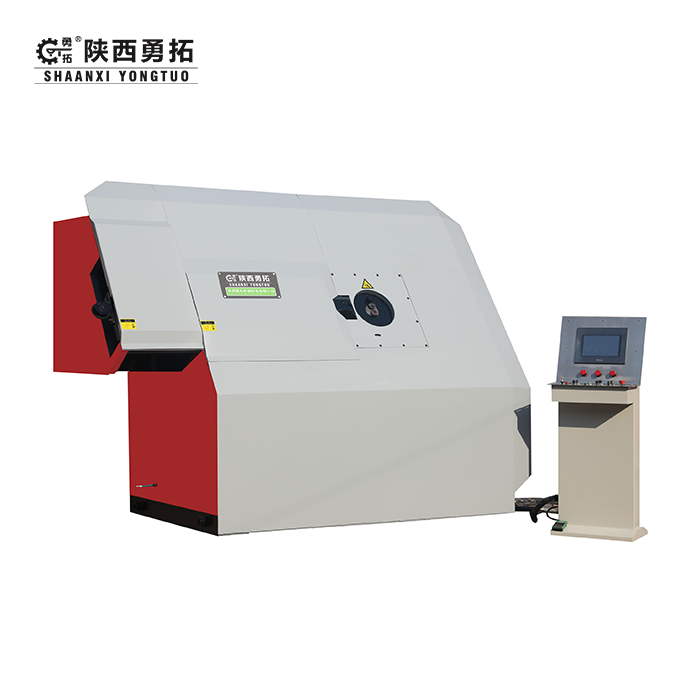

7.Planetary reducer used for torque transmission during bending, resulting in low noise, high precision, and long service life.

8.Multi-piece flexible clamping system effectively secures multiple rebars, ensuring consistent processing dimensions.

9.Optional automatic raw material feeding system reduces feeding workload."

Shaanxi Yongtuo: Your Trusted Rebar Shearing and Bending Workstation Manufacturer

Shaanxi Yongtuo Machinery Technology Co., Ltd, established in 2003, specializes in manufacturing Rebar Shearing and Bending Workstations with 20+ years of expertise. Our machines integrate advanced CNC technology, energy-saving designs, and robust after-sales support, ensuring superior performance for construction, prefab production, and infrastructure projects.

Why Choose Us?

✅ 20+ Years of R&D Expertise – Mature technology backed by 37 patents.

✅ Fully Automated Solutions – Reduce labor costs by 40%.

✅ 24/7 After-Sales Service – ≤12-hour fault response domestically.

✅ ISO-Certified Quality – Precision-engineered components for 100,000+ operation cycles.

✅ Global Reach – Machines exported to 30+ countries, including Southeast Asia and the Middle East.

Features & Advantages

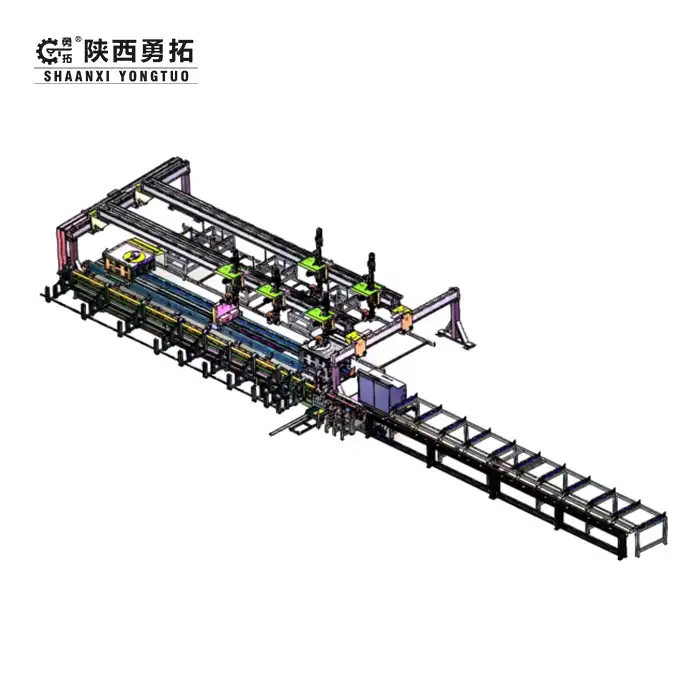

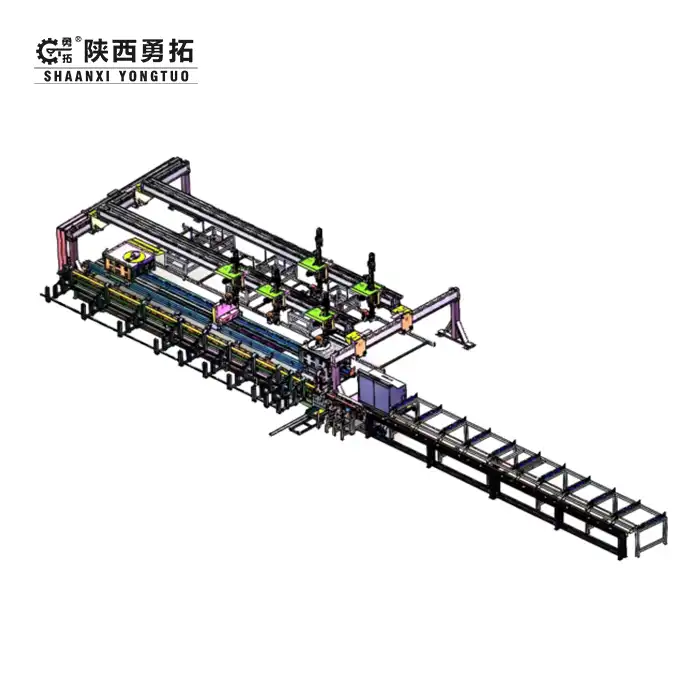

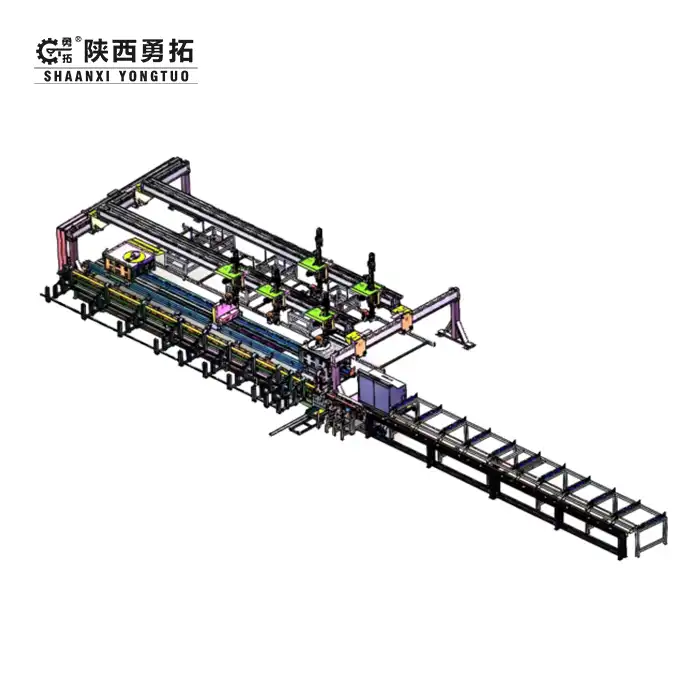

- All-in-One Automation: Combines feeding, cutting, bending, and collection in a single workflow.

- Adjustable Bending Speed: Process 8–40mm diameter rebars with ±1° accuracy.

- Robotic Material Handling: 3 sets of robotic arms for feeding + 2 for collection.

- Planetary Reducer: Low-noise, high-torque transmission for 50% longer lifespan.

- Multi-Station Bins: Collect 6+ specifications simultaneously.

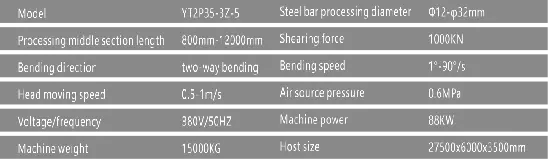

Product Parameters

|

Product Details

Our Rebar Shearing and Bending Workstation features a modular design with laser-cut steel frames, PLC-controlled operation, and touchscreen interfaces. Structural diagrams highlight the synchronized robotic arms and planetary reducer system for seamless material flow.

Application Areas

- High-Rise Buildings: Rapid processing of stirrups and beams.

- Bridge Construction: Custom bends for reinforced concrete.

- Prefab Factories: Batch production of mesh panels.

- Municipal Projects: Road barriers, drainage systems.

Customization Options

- Material Handling: Adapt to stainless steel or epoxy-coated rebars.

- Storage Bins: Expand capacity to 10+ specifications.

- IoT Integration: Real-time data monitoring via mobile apps.

Certifications

- CE, ISO 9001, and GB standards compliant.

- 3rd-party tested for safety and durability.

After-Sales Service

- 24-hour remote diagnostics.

- On-site maintenance within 48 hours (international).

- Free operator training + 1-year warranty.

Packaging

Before global shipping, our machines undergo a meticulous preparation process. First, they are carefully disassembled into manageable parts. Each part is then thoroughly coated with high - quality anti - rust oil, which forms a protective barrier against corrosion during long - distance transit. After that, all the components are neatly arranged and packed in sturdy wooden crates. These crates are designed to withstand the rigors of international shipping, ensuring that the machines reach their destinations in pristine condition, ready for seamless reassembly and use by our valued customers worldwide.

Company Introduction

Based in Xi'an, China, Shaanxi Yongtuo serves 500+ clients globally, including Sinomach and China Railway Group.

Our Factory

Our 12,000m² facility is a high - tech manufacturing powerhouse. It is equipped with state - of - the - art CNC machining centers, capable of producing intricate and precise components with utmost accuracy. The robotic welding lines ensure consistent and high - quality welds, significantly enhancing the durability of our products. Moreover, a dedicated QA team is constantly on - the - go. They meticulously inspect every product at multiple stages of production, from raw materials to the final assembly, guaranteeing that only top - notch items leave our facility and reach our valued customers.

Customer Visits

Over 200 clients toured our factory in 2023, witnessing live demonstrations of the Rebar Shearing and Bending Workstation.

Exhibitions

Our team of experts will be on - site, ready to guide you through the features and functions of our latest equipment. Whether it's our state - of - the - art earth - moving machinery or advanced concrete processing tools, you can test - drive them and see firsthand how they can revolutionize your construction projects. Don't miss this opportunity to engage with us, ask questions, and explore potential partnerships that can drive your business forward in the competitive construction industry.

FAQs

Q: How often is maintenance needed?

A: Monthly lubrication; annual planetary reducer inspection.

Q: Can it process curved rebars?

A: Yes! Customize bending angles via the PLC interface.

Q: Delivery time for EU orders?

A: 30–45 days after deposit.

Q: Warranty coverage?

A: 1 year for mechanical parts, 6 months for electrical systems.

Q: Do you offer financing?

A: Yes – 30% deposit, 70% balance before shipment.

Contact Us

Upgrade your productivity with the Rebar Shearing and Bending Workstation!

📧 sxyongtuo@gmail.com

YOU MAY LIKE

_1744680888628.png)