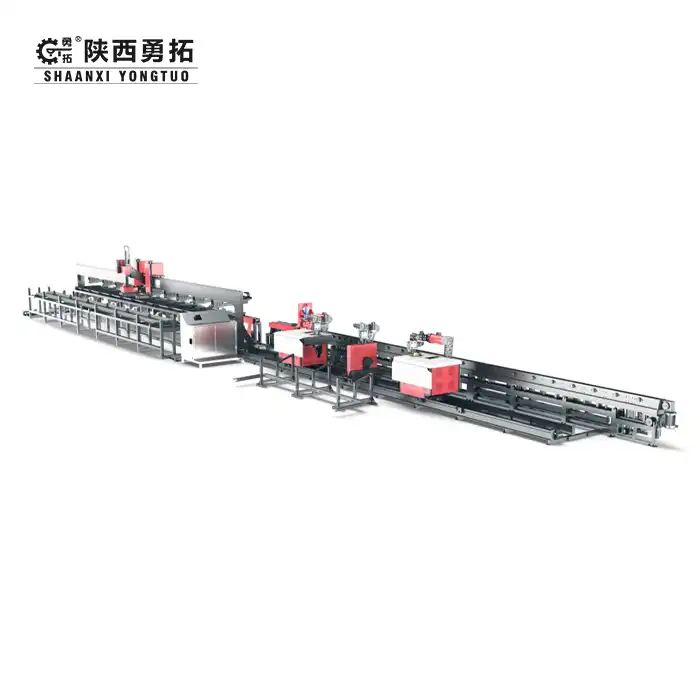

Shaanxi Yongtuo Machinery Technology Co., Ltd – Your Trusted Bar Shear Bend Robot Production Line Partner

As a leading Bar Shear Bend robot production line manufacturer since 2003, Shaanxi Yongtuo combines 20+ years of R&D expertise with 37 patented technologies to deliver fully automated, energy-efficient systems. Our solutions simplify complex tasks like feeding, cutting, bending, and collection, ensuring precision for industries like automotive, construction, and aerospace.

Why Choose Us?

✅ 20+ Years of Expertise: Mature R&D team with CE, ISO, and TÜV certifications.

✅ End-to-End Automation: Integrated processes reduce labor costs by up to 70%.

✅ Global Support: 24/7 remote diagnostics + ≤12-hour on-site response (domestic).

✅ Energy Savings: 30% lower energy consumption compared to hydraulic systems.

✅ Customizable: Adaptable to materials like titanium alloys or high-strength steel.

Features & Advantages

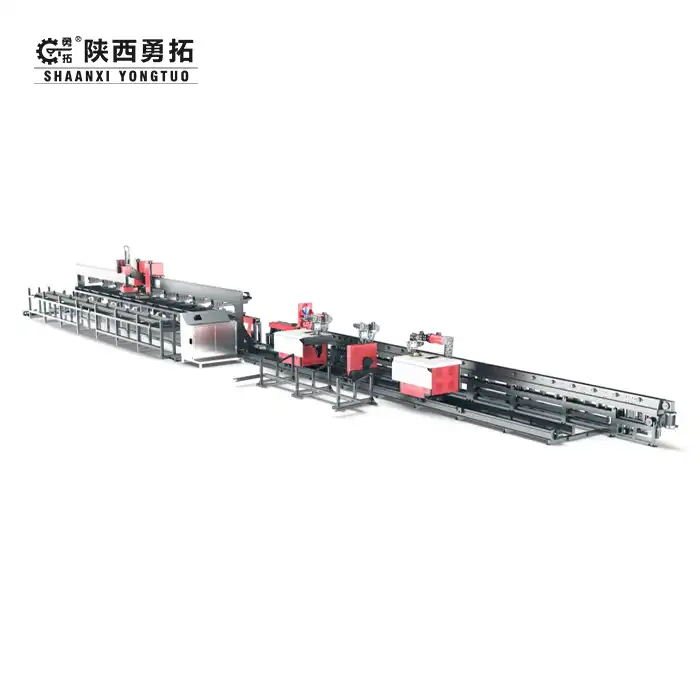

✨ All-in-One Automation: Seamlessly handles feeding, cutting, bending, and collection.

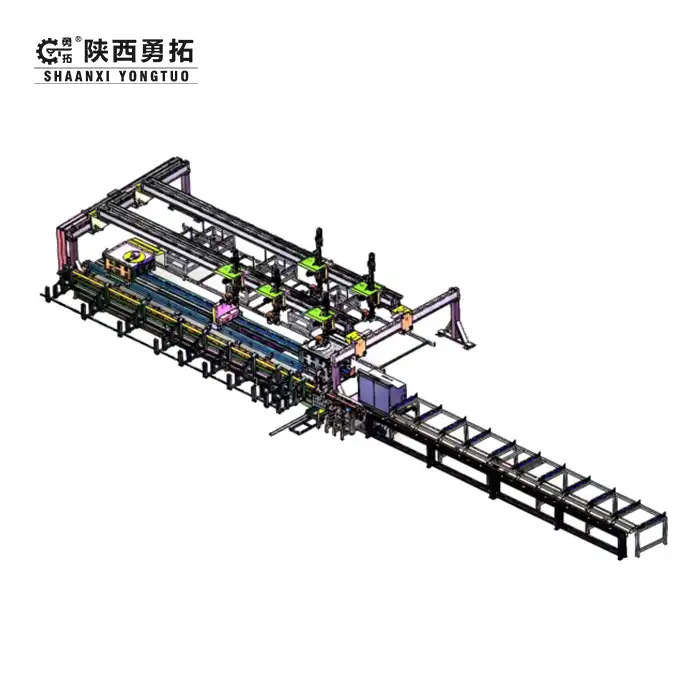

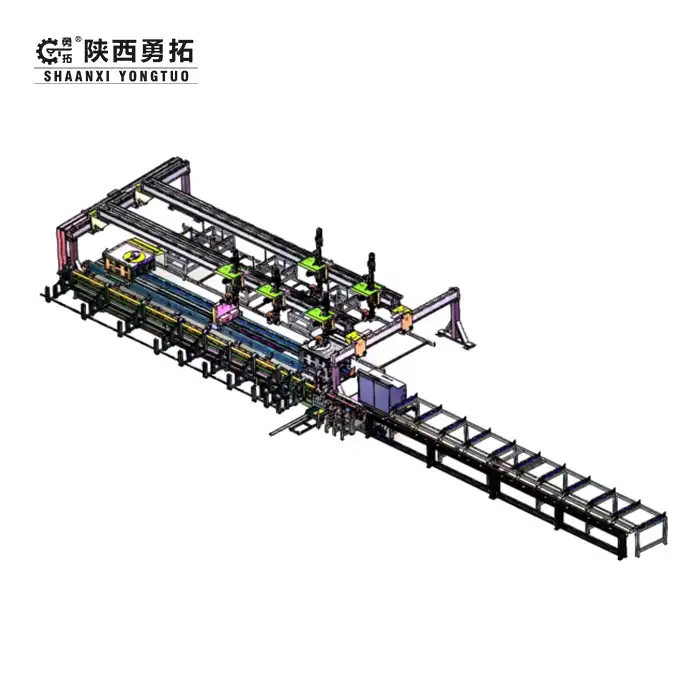

✨ Triple Robot Precision: Three-axis robots ensure smooth material handling and product stacking.

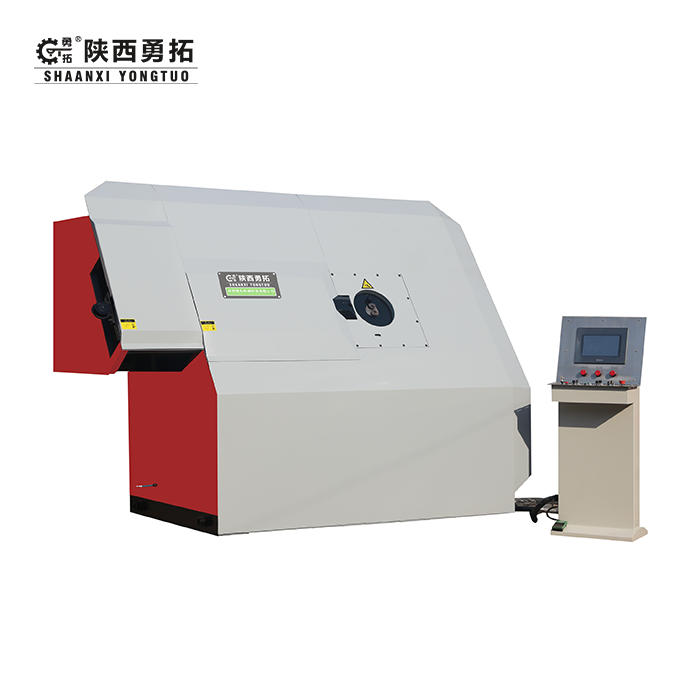

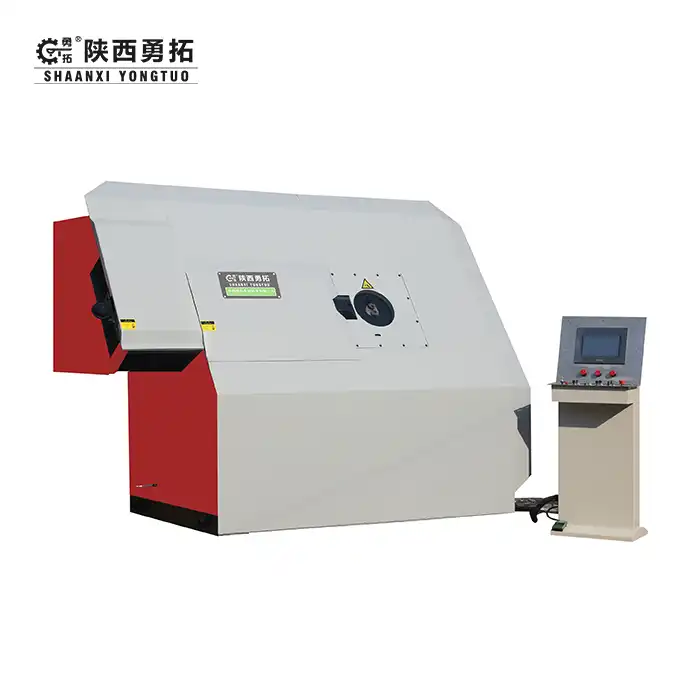

✨ Adjustable Bending Speed: Set rotation speeds from 10-60 RPM for flexible workflows.

✨ Planetary Reducers: High-torque, low-noise transmission for 50,000+ hour lifespans.

✨ Multi-Clamp System: Secures 5-20 rebar batches with ±0.5mm dimensional consistency.

✨ Optional Feeding System: Automate raw material loading to reduce manual labor.

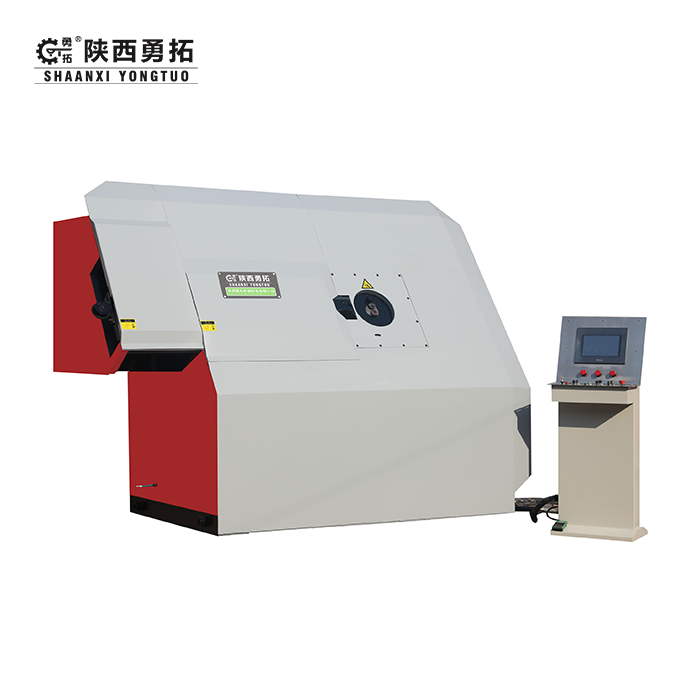

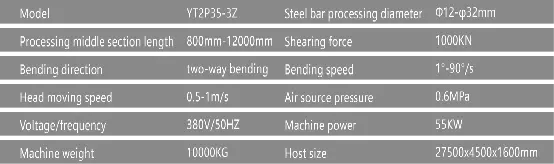

Product Parameters

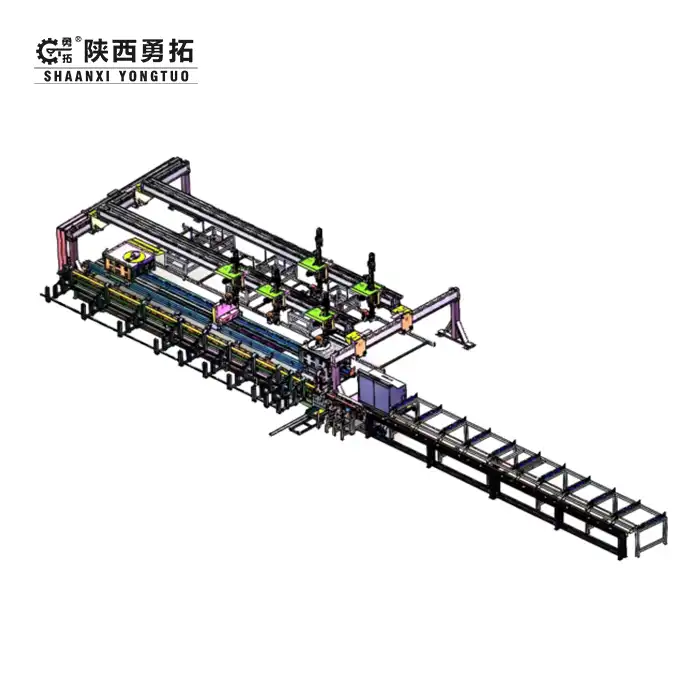

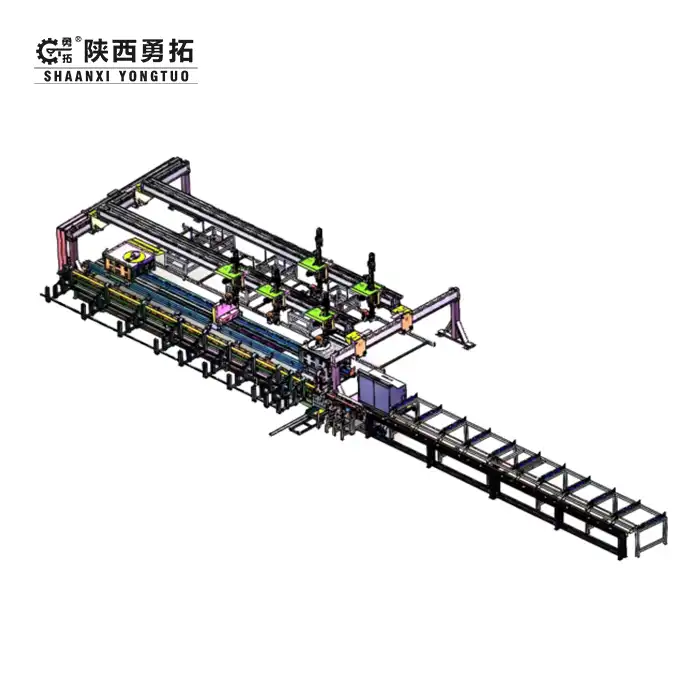

Product Structure Diagram

Our Bar Shear Bend robot production line's modular design allows easy integration with CAD/CAM software.

Application Areas

- Automotive: Battery trays, chassis components.

- Construction: Reinforced steel bars, prefab elements.

- Aerospace: Titanium alloy brackets, engine parts.

- Energy: Solar panel frames, wind turbine bases.

Customization Options

- Add IoT sensors for real-time performance tracking.

- Upgrade to AI vision for defect detection.

- Tailor dimensions for factory space constraints.

Certifications

🔹 CE Mark 🔹 ISO 9001 🔹 SGS 🔹 TÜV

After-Sales Service

- 24/7 Remote Support: Instant troubleshooting via Yongtuo's proprietary app.

- On-Site Maintenance: Technicians dispatched within 12 hours (China).

- Spare Parts Guarantee: 10-year availability for critical components.

Packaging

Reinforced wooden crates with waterproof coating and shock-absorbent foam.

Company Introduction

Founded in 2003, Shaanxi Yongtuo has been a leading force in the metal processing industry for over two decades. We serve 50+ countries with our state - of - the - art metal processing solutions. Our expansive 20,000㎡ factory in Xi'an is a hub of innovation. The 200+ engineers on our team are dedicated to sustainable innovation, constantly researching and developing new techniques. This ensures that our metal processing not only meets the highest quality standards but also minimizes environmental impact, making us a preferred choice for global clients seeking both performance and eco - friendliness.

Customer Visits

These clients, hailing from various industries, were impressed by our innovative manufacturing processes, like those in our Steel Bar Shearing and Bending Automaton. They engaged in in - depth discussions, exploring potential collaborations. Many of them have since placed orders, further solidifying our position as a go - to partner for advanced industrial solutions.

Exhibitions

Our team of experts will be on - site, ready to showcase the advanced features of our products, such as the Steel Bar Shearing and Bending Automaton. You'll see firsthand how it can revolutionize your production processes, increasing efficiency and precision. Don't miss this opportunity to engage with us, ask questions, and explore potential partnerships that can drive your business forward in 2024 and beyond.

FAQ

Q: Can this line process stainless steel?

A: Yes! Our machines handle materials up to HRC 45 hardness.

Q: What's the ROI timeframe?

A: Most clients achieve payback in 8-14 months via labor/energy savings.

Q: Do you provide installation training?

A: Yes – 3-day onsite training included.

Q: How to integrate with my existing MES?

A: We offer API/OPC UA protocols for seamless connectivity.

Q: What's the lead time?

A: 45-60 days after deposit.

Contact Us

📧sxyongtuo@gmail.com

Request a free material test or ROI analysis today!

Bar Shear Bend Robot Production Line – Where Innovation Meets Reliability. Trust Yongtuo for Smarter Manufacturing. 🌐✨

YOU MAY LIKE

_1744680888628.png)