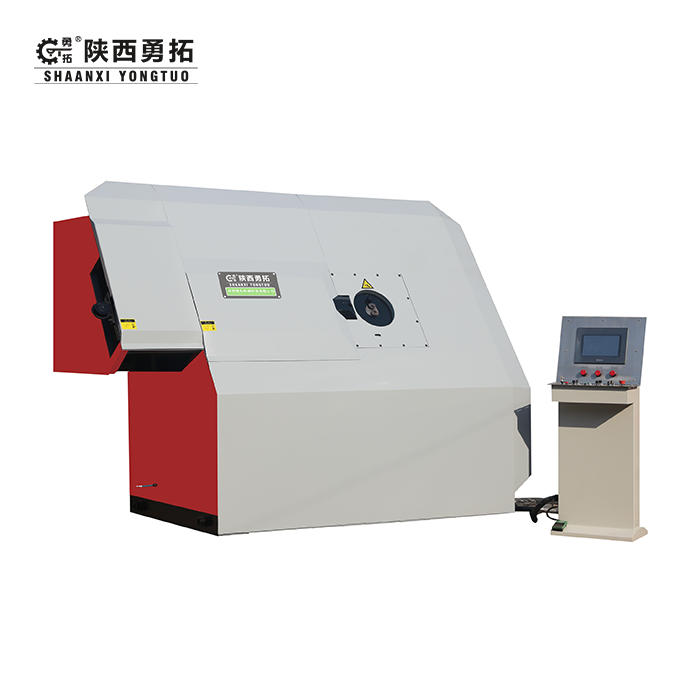

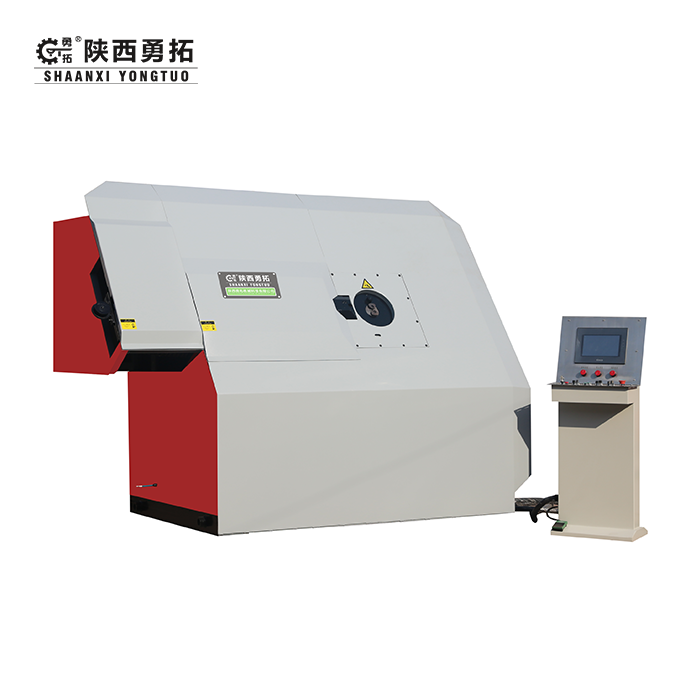

2.Bending rotation speed is adjustable, providing high processing flexibility.

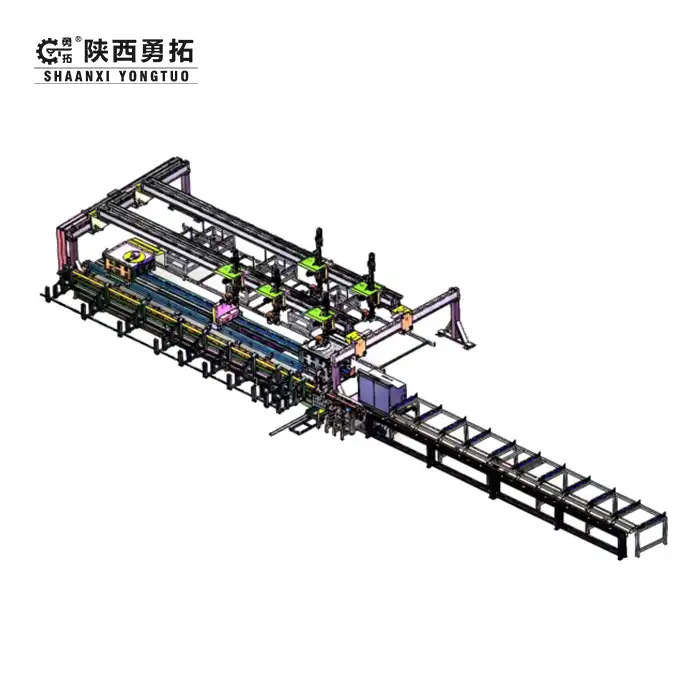

3.Equipped with three sets of three-axis robotic arms for bending material feeding.

4.Equipped with two sets of three-axis robotic arms for finished product collection.

5.Separate execution of bending feeding and finished product collection increases production efficiency.

6.Multi-station finished product storage bins allow simultaneous collection of products of various specifications.

7.Planetary reducer used for torque transmission during bending, resulting in low noise, high precision, and long service life.

8.Multi-piece flexible clamping system effectively secures multiple rebars, ensuring consistent processing dimensions.

9.Optional automatic raw material feeding system reduces feeding workload."

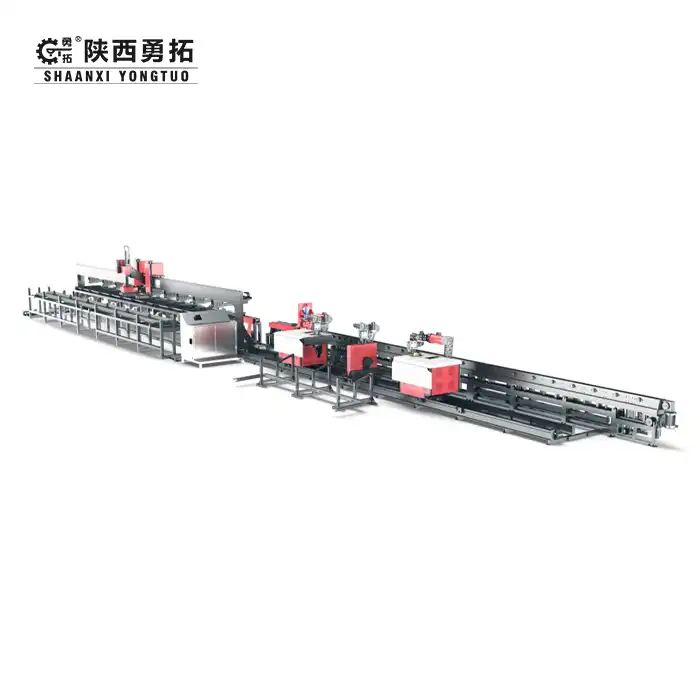

Premium Steel Bar Shearing and Bending Station Manufacturer

Shaanxi Yongtuo Machinery Technology Co., Ltd, established in 2003, specializes in designing Steel Bar Shearing and Bending Stations that combine automation, precision, and durability. With 37 patents, a dedicated R&D team, and 20+ years of global export experience, we deliver machinery trusted by construction giants and metalworking industries worldwide.

Why Choose Us? ✅

- Advanced Technology: Over 37 patents ensure cutting-edge innovation.

- Simplified Operation: Intuitive CNC controls reduce training time.

- Energy-Saving Design: 15% lower power consumption vs. competitors.

- Reliable Performance: 98% uptime guarantee for high-volume projects.

- Global Service: 24/7 remote diagnostics + ≤12-hour on-site response (domestic).

-

Key Features & Advantages 🏆

✅ Fully Automated Workflow: Integrates feeding, cutting, bending, and collection.

✅ Adjustable Bending Speed: 5 programmable presets for diverse rebar specifications.

✅ Triple Robotic Arms: 3 sets for bending, 2 for collection – 30% faster than manual systems.

✅ Planetary Reducer: Noise <75 dB, precision ±0.5mm, lifespan 50,000+ hours.

✅ Multi-Bin Storage: Collect 6+ product sizes simultaneously.

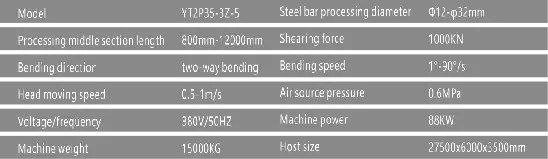

Technical Parameters 📊

Product Structure & Design 🏗️

Our CNC Steel Bar Processing Station features a modular design with laser-guided alignment (accuracy ±0.3mm) and IP54-rated components for dust/water resistance.

Application Areas 🌍

- Construction: Bridges, tunnels, high-speed rail.

- Prefab Factories: Pre-stressed concrete beams, columns.

- Metalworks: Custom rebar grids, hooks, stirrups.

Customization Options 🛠️

- Material Feeding: Add automated conveyor systems.

- Software: Integrate with ERP/MES platforms.

- Voltage: 220V/380V/415V configurations.

Certifications 📜

CE, ISO 9001, and SGS certifications guarantee compliance with EU safety and eco-directives.

After-Sales Service 🔧

- 2-year warranty + lifetime technical support.

- Spare parts delivered ≤72 hours (global).

Packaging 📦

Export-standard wooden crates with waterproof film and shock-absorbent padding.

Factory Tour 🚚

Visit our 20,000㎡ facility in Xi'an to see CNC laser cutters and robotic welding in action. As you step into our state - of - the - art factory, you'll be greeted by a dynamic manufacturing environment. The CNC laser cutters, with their high - precision beams, effortlessly slice through various materials, creating intricate shapes with micron - level accuracy. Meanwhile, the robotic welding stations operate with remarkable speed and consistency, producing flawless welds on a wide range of components. Our knowledgeable staff will be on - hand to explain the processes, answer your questions, and show you how these advanced technologies can revolutionize your own production requirements.

Global Clients 🤝

Recent visitors to our facility include industry - leading entities such as Vietnam's Vingroup, a conglomerate with diverse interests in real estate, healthcare, and more. Saudi Aramco contractors, representing one of the world's largest oil companies, also paid us a visit. Additionally, the mighty China Railway Group, renowned for its global infrastructure projects, stopped by. These esteemed visitors were keen to explore our advanced manufacturing capabilities, innovative product lines, and potential for future collaborations. Their presence not only validates our standing in the international market but also opens doors for exciting new business opportunities across different sectors and regions.

Exhibitions 🎪

Our teams at both events will be eager to engage with you, offer live demonstrations, and discuss how our solutions can enhance your projects, whether you're a contractor, engineer, or industry professional. Don't miss these opportunities to connect and stay ahead in the industry.

FAQs ❓

Q: Can it bend stainless steel rebars?

A: Yes! Configured for HRB400/500, 304/316 stainless steel.

Q: How to reduce maintenance costs?

A: Self-lubricating bearings require only annual greasing.

Q: What's the ROI timeframe?

A: 14-18 months via labor cost savings.

Q: Training provided?

A: Free 3-day onsite training + 24/7 video manuals.

Q: Lead time for custom orders?

A: 45-60 days after deposit.

Request a Quote Today! 📞

Email: sxyongtuo@gmail.com

YOU MAY LIKE

_1744680888628.png)