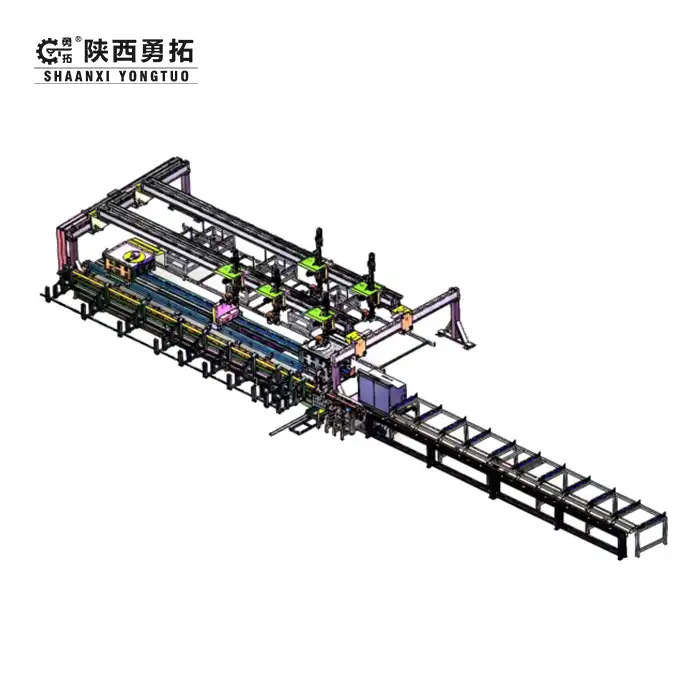

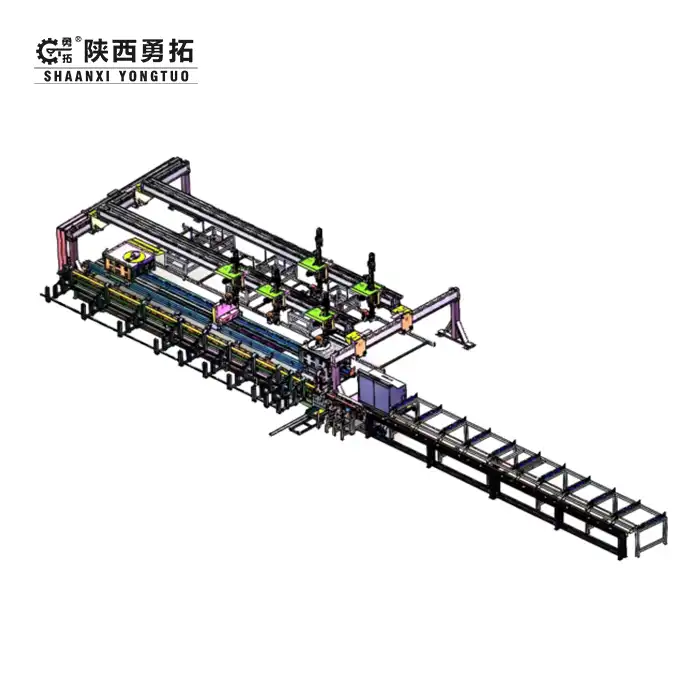

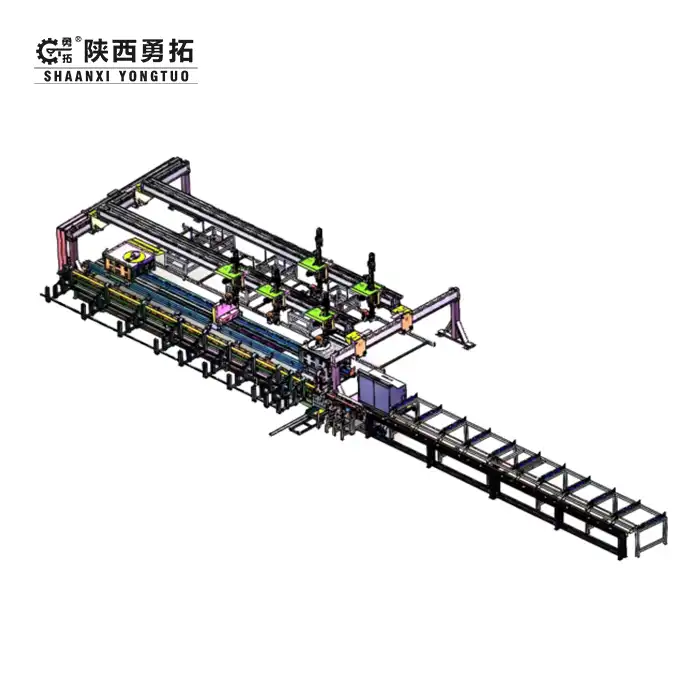

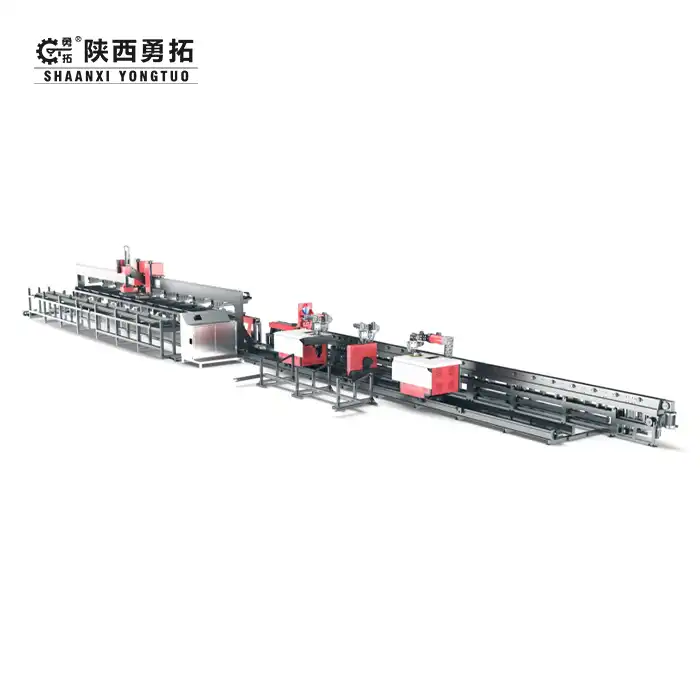

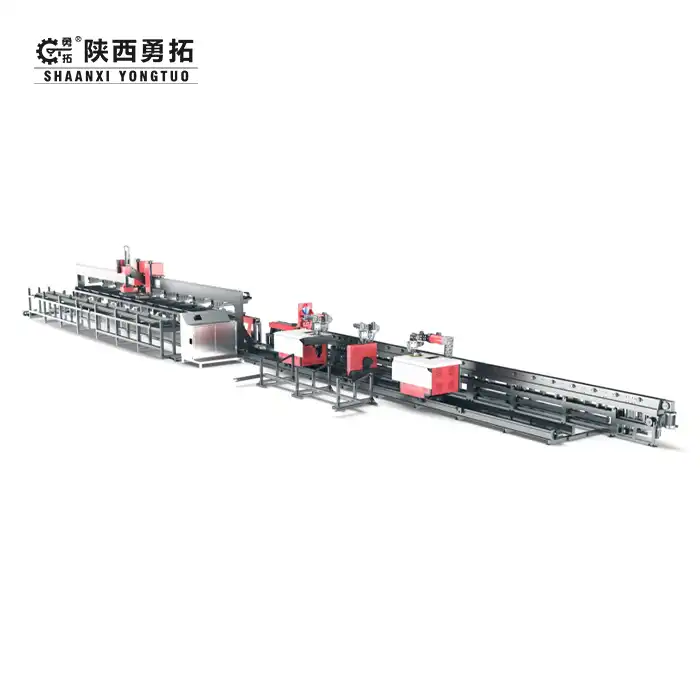

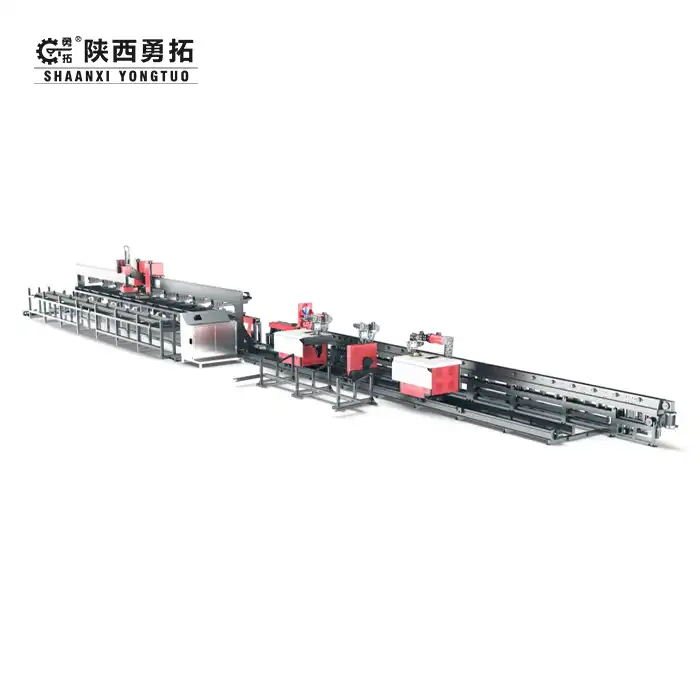

2.Equipped with three sets of three-axis robots for bending material feeding and finished product collection.

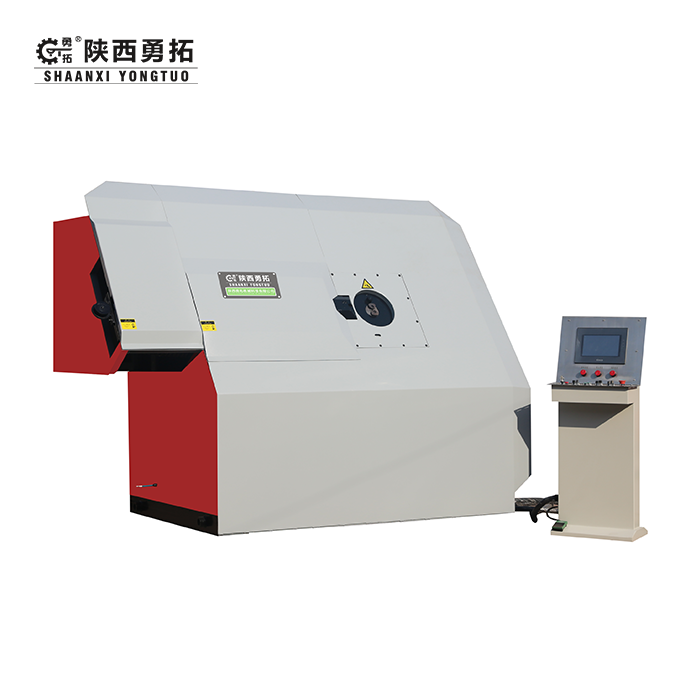

3.The bending rotation speed can be set arbitrarily, offering greater processing flexibility.

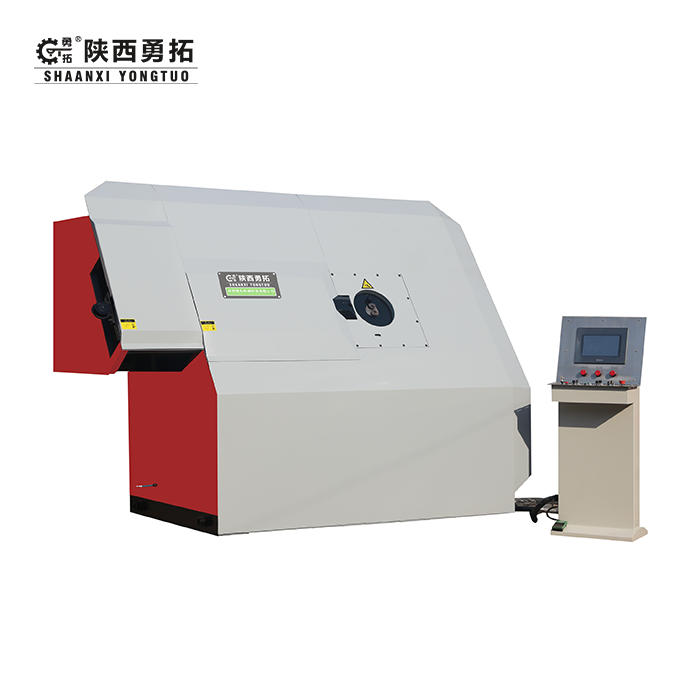

4.The planetary reducer is used for torque transmission during bending, ensuring low noise, highprecision,and long service life.

5.The middle clamping system uses a multi-piece flexible clamp, effectively securing multiple rebars and ensuring consistent dimensions for all processed rebars.

6.Optional automatic raw material feeding system is available, reducing the labor intensity of feeding operations."

Shaanxi Yongtuo Machinery Technology Co., Ltd

As a leading Steel Bar Shearing and Bending Automaton manufacturer and supplier, Shaanxi Yongtuo combines 17+ years of expertise with cutting-edge CNC technology. Our machines excel in precision, energy efficiency, and durability, backed by a global service network and ISO/CE certifications.

Why Choose Us?

✅ 17+ Years of R&D Excellence: Mature engineering team with 37 patented technologies.

✅ End-to-End Automation: Integrated feeding, cutting, bending, and collection in one machine.

✅ Global Support: 24/7 remote diagnostics + ≤12-hour on-site response (domestic).

✅ Proven Reliability: Trusted by contractors in 30+ countries for bridges, tunnels, and smart factories.

✅ Custom Solutions: Adaptable to non-standard rebar sizes (6-50mm) and complex bends.

6 Game-Changing Features

🔹 3-Axis Robot Integration: Triple robotic arms for seamless material handling and finished product stacking.

🔹 Smart Speed Control: Adjust bending rotation (0-30 RPM) for diverse project requirements.

🔹 Planetary Reducer Tech: 60% quieter operation + 50,000-hour service life guaranteed.

🔹 Multi-Clamp System: Hold up to 12 rebars simultaneously with ±0.5mm dimensional consistency.

🔹 Energy-Saving Mode: 30% lower power consumption vs. industry averages.

🔹 Auto Feed Add-On: Optional conveyor system for continuous production lines.

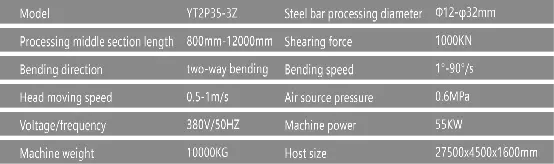

Technical Specifications

Application Areas

🏗️ Mega Infrastructure: High-speed rail, wind turbine bases, and seismic-resistant structures.

🏭 Precast Concrete Plants: Batch processing of stirrups, U-shaped hooks, and spiral rebars.

⚡ Renewable Energy: Solar farm mounting systems and hydropower reinforcement cages.

🏗️ Smart Factories: IoT-enabled production lines with real-time data tracking.

Customization

• Material Compatibility: Customize clamps for epoxy-coated, stainless, or ribbed bars.

• Software Integration: Compatible with Tekla, AutoCAD, and Revit designs.

• Safety Upgrades: Add laser scanners or emergency stop curtains.

Certifications

• CE Mark (Machine Directive 2006/42/EC)

• ISO 9001:2015 Quality Management

• SIL-2 Safety Integrity Level (Optional)

After-sales service

• Pre-Sales: Free process optimization consulting.

• Installation: On-site training for 3-5 operators.

• Post-Sales: Lifetime technical support + 2-year warranty.

Logistics and transportation

🛡️ Weatherproof plywood crates with anti-corrosion coating.

🛡️ GPS-tracked containers for real-time delivery monitoring.

About Shaanxi Yongtuo

Established in 2003, our company has been at the forefront of the steel processing industry for over two decades. Over the years, we have successfully delivered 3,200+ steel processing systems to clients all around the globe, solidifying our reputation as a reliable and innovative provider. Our state - of - the - art smart factory, located in Xi'an, is a technological marvel. Spanning an impressive 46,000m², it incorporates advanced manufacturing technologies. The factory features robotic welding, which ensures precise and consistent welds, enhancing the quality of our products. Moreover, we utilize 5D simulation testing. This cutting - edge testing method allows us to thoroughly evaluate the performance of our steel processing systems under various real - world scenarios, guaranteeing their reliability and efficiency before they reach our customers.

Exhibition

We regularly attends major industry exhibitions at home and abroad, including Bauma China, Canton Fair, and international metalworking expos. These platforms allow us to showcase our latest CNC solutions, exchange insights with global partners, and explore new business opportunities. Our presence at these events reflects our commitment to innovation, quality, and global cooperation.

FAQ

Q: Can it process curved rebars for spiral piles?

A: Absolutely! Our software supports 3D helical bending up to 360°.

Q: What's the lead time for an EU order?

A: Standard units ship in 45 days; expedited 30-day slots available.

Q: Do you provide bending mold templates?

A: Yes – 12 standard molds included; custom designs take 7-10 days.

Q: How to reduce shear blade wear?

A: Use our carbide-coated blades (optional) – lasts 3x longer.

Q: Is remote software updating possible?

A: Yes, via encrypted VPN connection.

Get Your Customized Steel Bar Shearing and Bending Automaton Quote!

📧 Email: sxyongtuo@gmail.com

Why Settle for Less?

Opt for our Steel Bar Shearing and Bending Automaton, the very machinery that played a pivotal role in constructing Asia's longest immersed tunnel. This high - tech equipment is engineered with precision and advanced features, delivering unrivaled performance in steel bar processing. It has been rigorously tested and proven in large - scale infrastructure projects, ensuring consistent and accurate shearing and bending operations. By choosing our automaton, you're not just getting a machine; you're investing in a solution that will revolutionize your production process. Let's work together today to engineer a significant leap in your productivity, enabling you to take on more ambitious projects with confidence and efficiency.

YOU MAY LIKE

_1744680888628.png)