2.Bending rotation speed is adjustable, providing high processing flexibility.

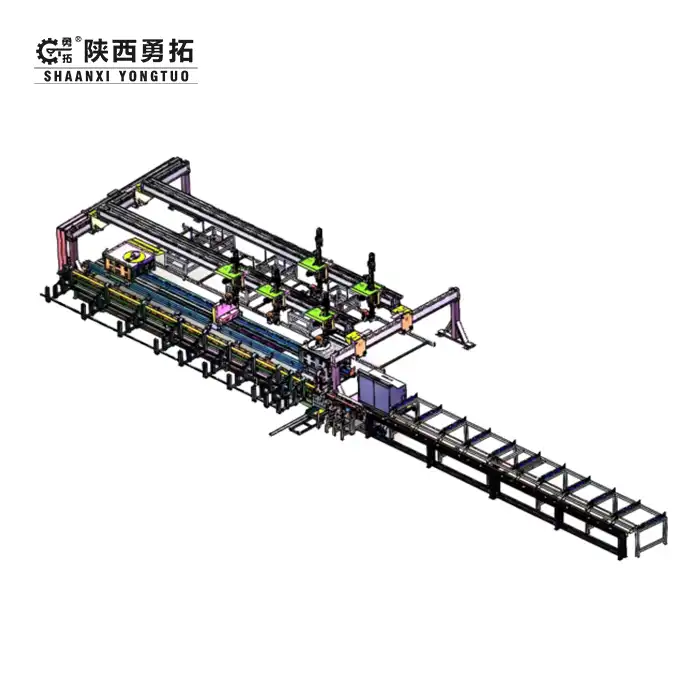

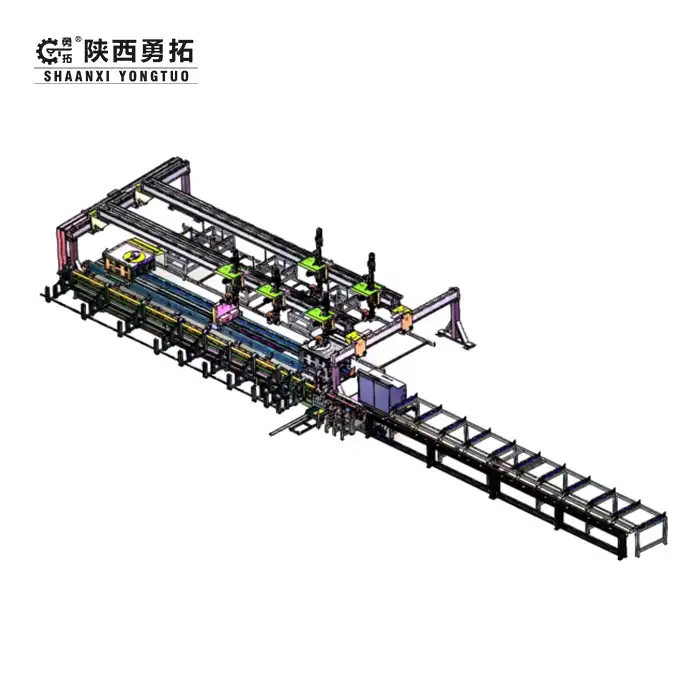

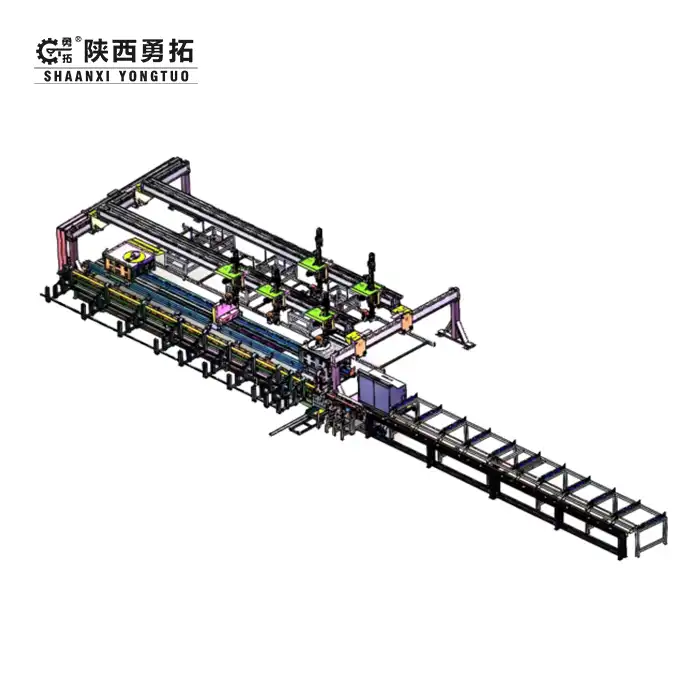

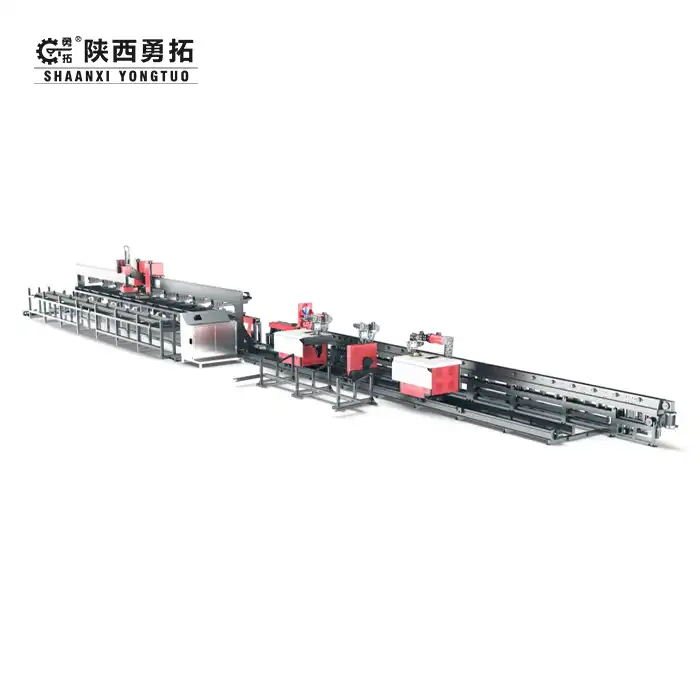

3.Equipped with three sets of three-axis robotic arms for bending material feeding.

4.Equipped with two sets of three-axis robotic arms for finished product collection.

5.Separate execution of bending feeding and finished product collection increases production efficiency.

6.Multi-station finished product storage bins allow simultaneous collection of products of various specifications.

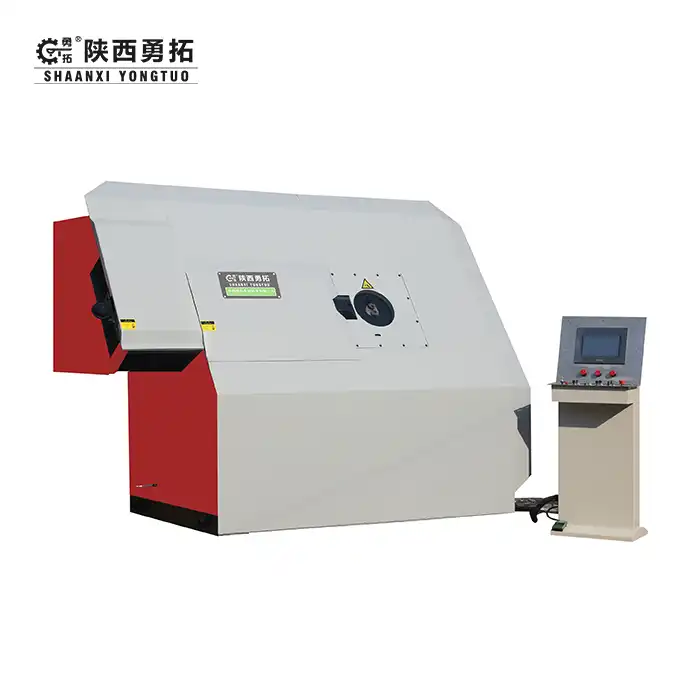

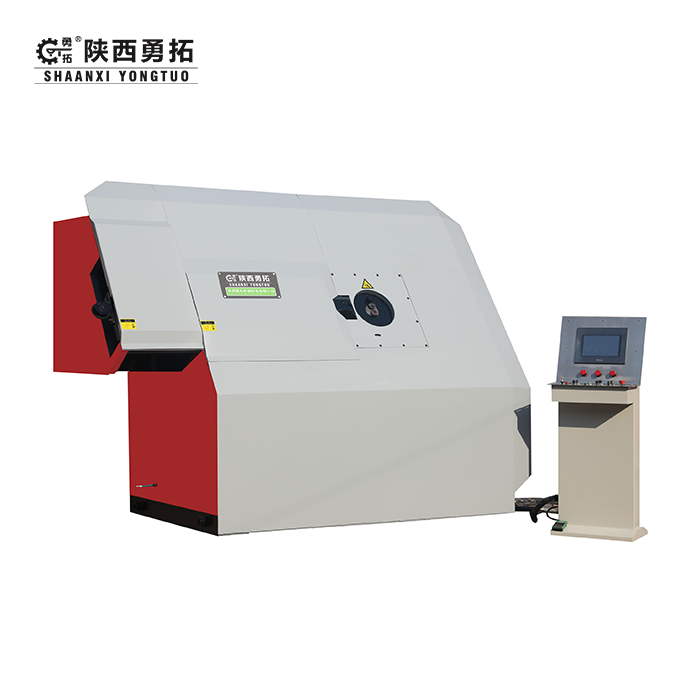

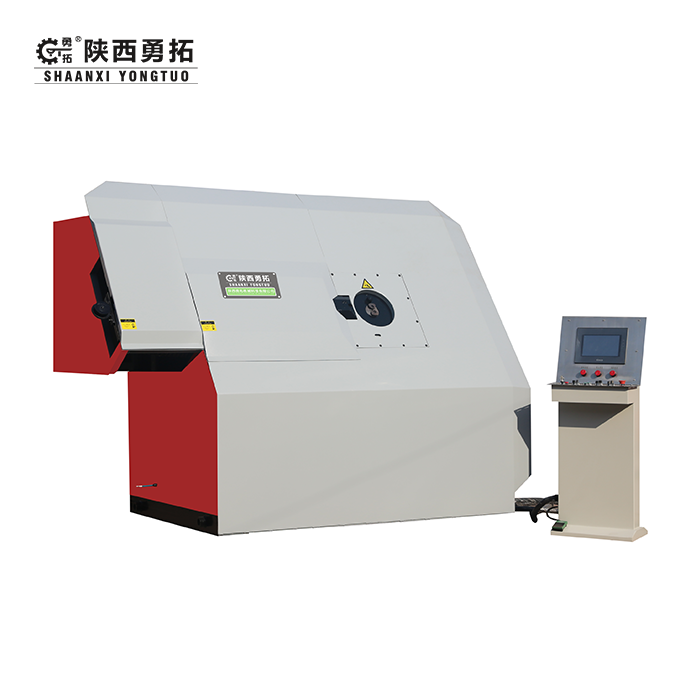

7.Planetary reducer used for torque transmission during bending, resulting in low noise, high precision, and long service life.

8.Multi-piece flexible clamping system effectively secures multiple rebars, ensuring consistent processing dimensions.

9.Optional automatic raw material feeding system reduces feeding workload."

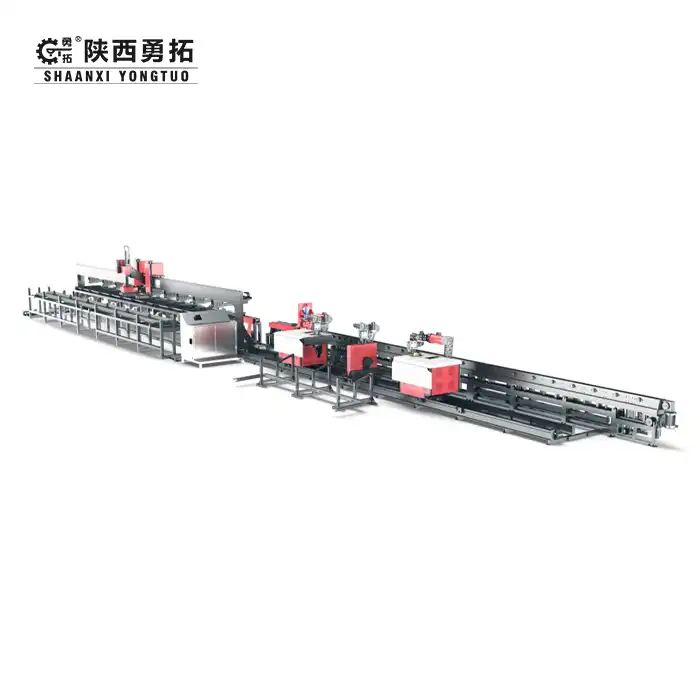

High-Efficiency Rod Shearing and Bending Machine Your Trusted Partner for Automated Rebar Processing

Shaanxi Yongtuo Machinery Technology Co., Ltd, established in 2003, specializes in manufacturing premium Rod Shearing and Bending Machines designed for precision, durability, and unmatched productivity. With 37 patents, a mature R&D team, and 20+ years of global export experience, our machines integrate cutting-edge CNC technology to streamline steel bar processing for construction, manufacturing, and renewable energy sectors.

Why Choose Shaanxi Yongtuo's product?

- ✅ Advanced Automation: Fully automated feeding, cutting, bending, and collection reduce labor costs by 40%.

- ✅ Proven Reliability: Planetary reducers and multi-clamp systems ensure ±0.5° bending accuracy.

- ✅ Energy Efficiency: 15% lower energy consumption vs. industry standards.

- ✅ Global Support: 24/7 remote diagnostics + on-site service within ≤12 hours (China).

Key Features & Advantages

- All-in-One Automation: Combines feeding, fixed-length cutting, bending, and sorting into one seamless process.

- Adjustable Speed: CNC-controlled bending rotation (5-30 RPM) for diverse material specs.

- Dual Robotic Arms: 3-axis robotic arms for precision feeding and product collection.

- High-Capacity Storage: Multi-bin system handles 6+ rebar sizes simultaneously.

- Low Noise Design: ≤75 dB operation for safer worksites.

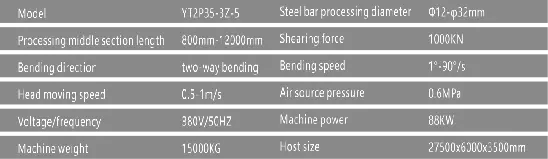

Technical Specifications

Applications

- Construction: High-rise buildings, bridges, prefabricated components.

- Manufacturing: Automotive parts, metal furniture, shipbuilding.

- Renewable Energy: Solar panel frames, wind turbine bases.

- Infrastructure: Railways, highways, hydropower projects.

Customization Options

- Material Compatibility: Adaptable to stainless steel, alloy steel, or threaded rebars.

- Software Integration: Optional ERP/BIM connectivity for real-time data tracking.

- Feeding Systems: Add automated raw material loaders for 24/7 operation.

Certifications & Compliance

- CE, ISO 9001, and GB standards certified.

- Eco-friendly design meets EU noise/emission regulations.

After-Sales Service

- Warranty: 2-year limited warranty on critical components.

- Training: Free on-site operator training.

- Spare Parts: Global network ensures 72-hour delivery.

Packaging & Shipping

- Wooden crates with waterproof coating for international shipping.

- Custom packaging available for bulk orders.

About Shaanxi Yongtuo

Founded in 2003, we've steadily ascended to become a Rod Shearing and Bending Machine manufacturer. Our 50,000㎡ factory serves as the epicenter of our operations, housing state - of - the - art manufacturing equipment. The 200+ technicians on our team, with their vast expertise, continuously innovate and optimize our products. Our esteemed clients, such as Sinoma International and China Railway Group, rely on our high - precision CNC bending machines for their large - scale projects. Additionally, our global distributors in 30+ countries play a crucial role in making our top - notch products accessible worldwide, strengthening our position in the international market.

Customer Visits & Exhibitions

- 2023 Highlights: Showcased at bauma CHINA and Middle East Concrete.

- Client Feedback: 98% satisfaction rate for post-sales responsiveness.

FAQ

Q: Can this machine process curved rebars?

A: Yes! Our adjustable robotic arms handle arcs, spirals, and right angles.

Q: What's the ROI timeframe?

A: Most clients achieve payback within 14 months via reduced labor and waste.

Q: Do you provide installation support?

A: Yes—our engineers assist with setup and calibration.

Q: How to adjust bending angles?

A: Use the touchscreen interface to preset 50+ angle programs.

Q: Is training included?

A: Free training covers operation, maintenance, and safety protocols.

Contact Us Today!

Upgrade your production with Yongtuo's Rod Shearing and Bending Machine—where innovation meets reliability.

📧 Email: sxyongtuo@gmail.com

Why Settle for Less?

Choose Shaanxi Yongtuo's product for precision engineering, faster ROI, and peace of mind. Our machine is meticulously crafted using advanced technology, ensuring every cut and bend is executed with utmost accuracy. This precision not only enhances the quality of your end products but also reduces material waste, contributing to a faster return on investment. With a robust build and reliable performance, you can operate it worry - free. Request a quote now! Our dedicated team will promptly assist you, providing all the details you need to make an informed decision for your production needs.

YOU MAY LIKE

_1744680888628.png)