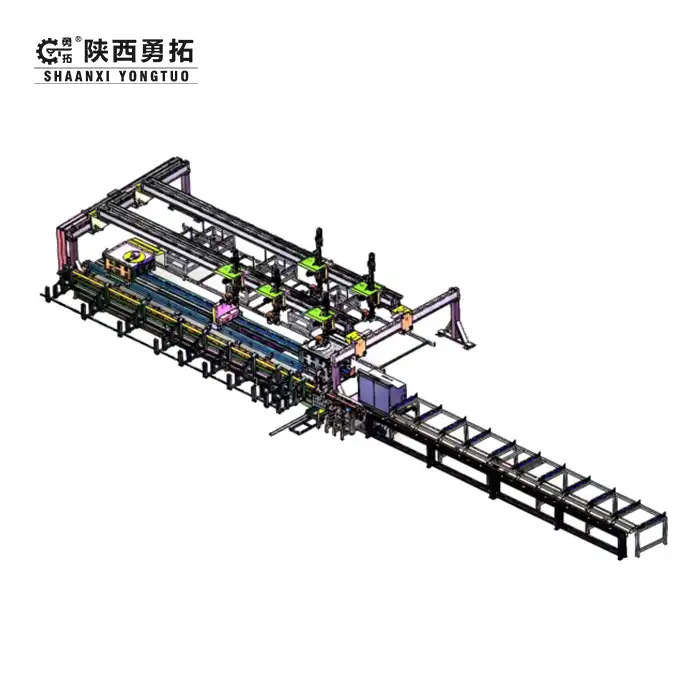

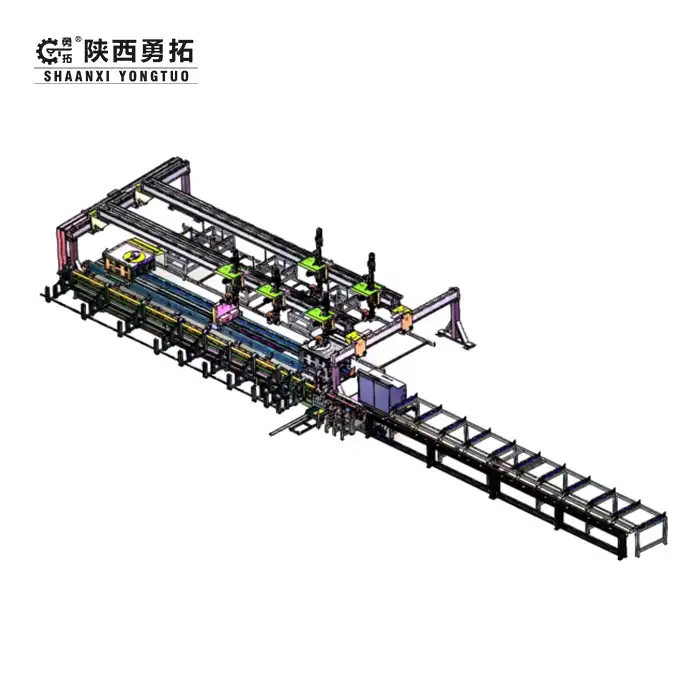

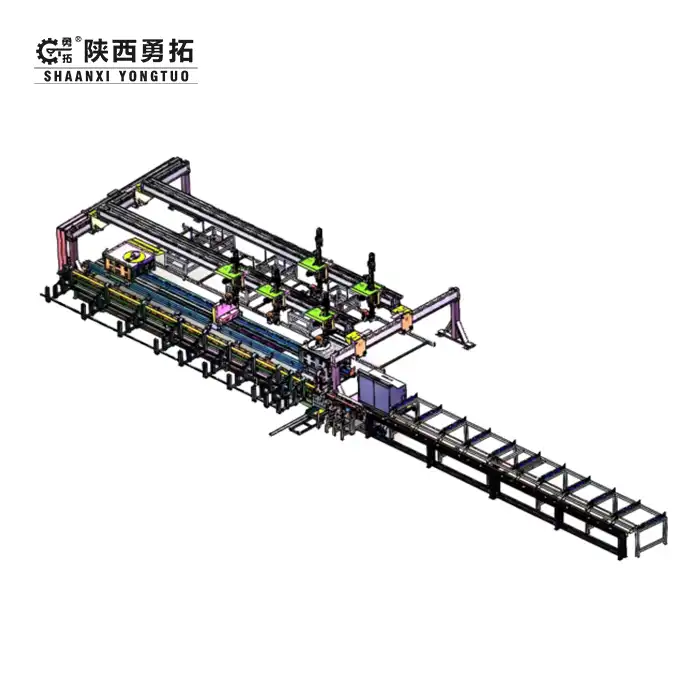

2.Equipped with three sets of three-axis robots for bending material feeding and finished product collection.

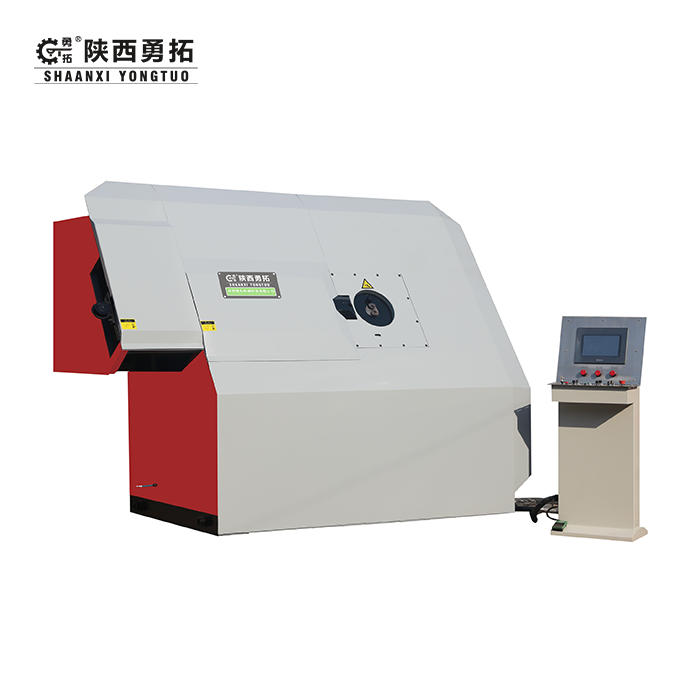

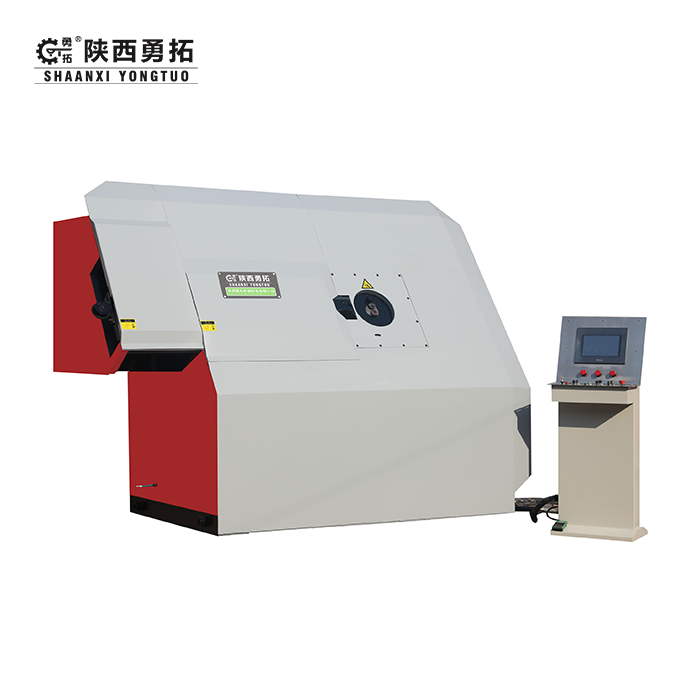

3.The bending rotation speed can be set arbitrarily, offering greater processing flexibility.

4.The planetary reducer is used for torque transmission during bending, ensuring low noise, highprecision,and long service life.

5.The middle clamping system uses a multi-piece flexible clamp, effectively securing multiple rebars and ensuring consistent dimensions for all processed rebars.

6.Optional automatic raw material feeding system is available, reducing the labor intensity of feeding operations."

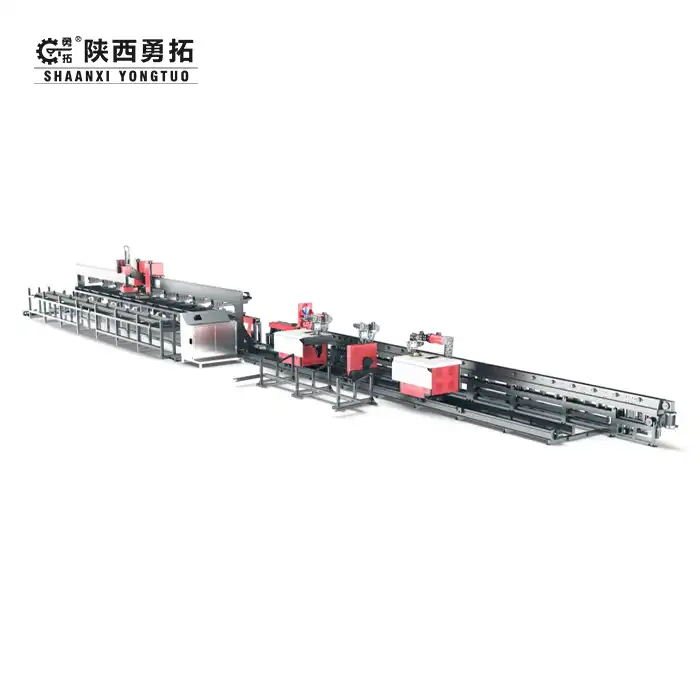

Bar Cutting Assembly Line: Precision Automation for Steel Processing

Shaanxi Yongtuo Machinery Technology Co., Ltd, established in 2003, is a leading Bar Cutting Assembly Line manufacturer with 37 patents and a global client base. Our fully automated systems integrate feeding, cutting, bending, and collection, delivering unmatched efficiency for construction, metalworking, and infrastructure projects. Trusted by companies like China Railway and precast factories, we combine advanced CNC technology with 24/7 support to ensure your operations never slow down.

Why Choose Our product?

- ✅ 20+ Years Expertise: Mature R&D team and ISO-certified production.

- ✅ Fully Automated Processing: 3 robotic arms eliminate manual handling.

- ✅ Energy-Saving Design: 30% lower power consumption vs. competitors.

- ✅ 12-HourFailureResponse: On-site support for urgent repairs.

- ✅ Customizable Workflows: Adapts to rebar diameters from 6mm to 40mm.

Key Features & Advantages

- ⚙️ Triple Robot System for seamless material transfer

- ⚙️ Adjustable bending speed (5-30 RPM) with planetary reducers

- ⚙️ Multi-piece clamps ensure ±1mm cutting accuracy

- ⚙️ Optional raw material conveyor (150kg capacity)

- ⚙️ IP65 waterproof control panel for harsh environments

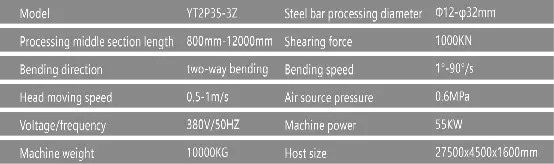

Technical Specifications

Application Fields

✅ High-Rise Construction: Engineered for projects where strength and precision are essential, ensuring long-lasting structural integrity.

✅ Bridge Reinforcement: Critical for enhancing durability and safety in vital transportation infrastructure.

✅ Precast Concrete Plants: Enables the production of high-quality, consistent precast components with improved efficiency.

✅ High-Speed Rail Tie Production: Ensures track stability and reliability for smooth, safe, and fast railway operations.

✅ Seismic-Resistant Beam Fabrication: Boosts structural resilience in buildings located in earthquake-prone regions.

✅ Steel Structure Warehouses: Ideal for building robust frameworks that support heavy loads and withstand harsh environmental conditions.

Certifications

CE, ISO9001, and China GB standards compliant. Our Bar Cutting Assembly Line are manufactured to meet the highest international standards, ensuring reliability, safety, and long-term performance in demanding industrial applications.

Customization

Our advanced machinery incorporates laser length measurement technology, boasting an impressive ±0.5mm precision. This high - accuracy measurement system ensures that each product's dimensions are consistently on point, minimizing errors and waste. To further streamline operations, we offer seamless ERP/MES software integration. This allows for real - time data sharing between production floors and management systems, enhancing overall efficiency and decision - making. Additionally, in response to the needs of arid regions, we provide dust - proof enclosures. These enclosures are designed to shield the equipment from the fine, abrasive dust, ensuring reliable performance even in harsh environmental conditions.

After-Sales Service

- 📞 24/7 WeChat/WhatsApp troubleshooting

- 🛠️ Free operator training (2-5 days)

- 🔧 2-year warranty on critical components

FAQ:

Q: Can this Bar Cutting Assembly Line process threaded steel?

A: Yes – our flexible clamps grip ribbed surfaces securely.

Q: What's the delivery time?

A: 30 - 45 days for standard models; an additional 15 days for custom orders.

Q: Do you accept payment by Letter of Credit (LC)?

A: Yes – we collaborate with over 98% of global clients through Telegraphic Transfer (TT) or Letter of Credit (LC).

Q: What is the maintenance schedule for the line?

A: To ensure optimal performance, we suggest conducting a routine inspection every three months. During this check, our technicians will inspect crucial components like motors, belts, and sensors to guarantee they are functioning properly.

Q: Can the line be integrated with existing production systems?

A: Definitely. Our line is engineered with modular characteristics, enabling seamless integration into most pre - existing production arrangements. We offer technical assistance to ensure a seamless connection and compatibility.

Q: How much floor space does the line need?

A: The standard model takes up around 20 square meters. Nevertheless, the size of custom - ordered lines may differ based on added features and alterations.

Contact Us

Need a Bar Cutting Assembly Line that boosts productivity? Email engineers at sxyongtuo@gmail.com for a free layout design.

YOU MAY LIKE

_1744680888628.png)