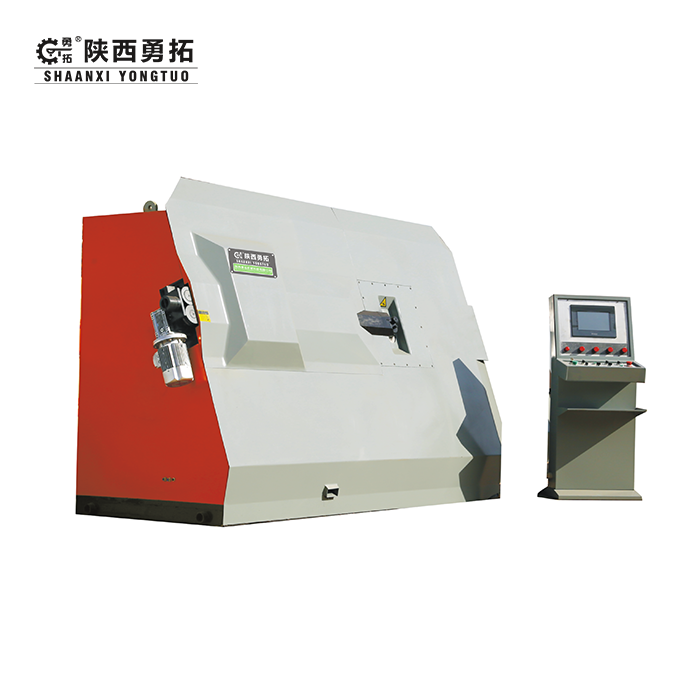

2.Servo-controlled wire feeding and bending, with high precision in feeding length and bending angle.

3.Servo controlled cutting, high cutting frequency, can cut continuously at high frequency.

4.Wire feeding and bending adopt planetary reducer as torque transmission, which has high torque transmission efficiency, high precision and long service life."

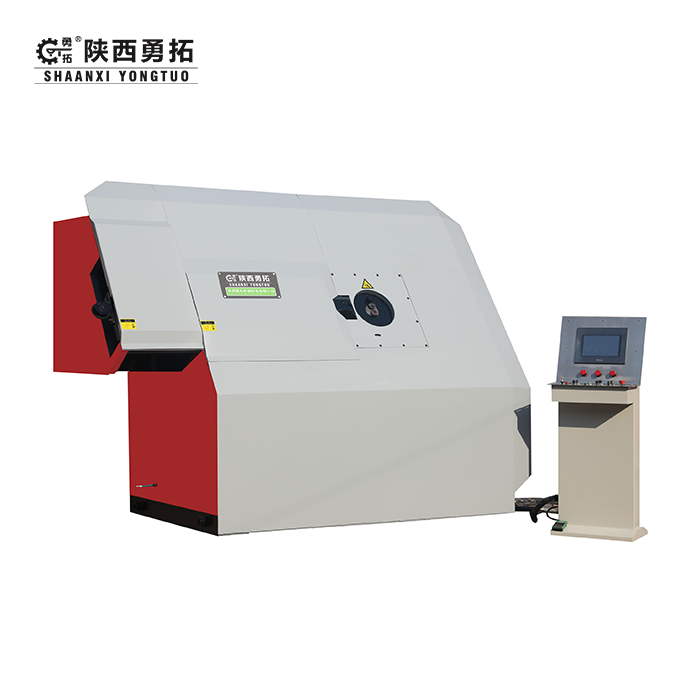

Shaanxi Yongtuo Machinery Technology Co., Ltd – Your Trusted Partner in Precision Rebar Processing

For over 20 years, Shaanxi Yongtuo Machinery Technology Co., Ltd has delivered Automatic Rebar Bending production line that combine cutting-edge technology with unmatched reliability. As a leading manufacturer with 37 patents, our solutions are trusted by construction giants and manufacturers worldwide to reduce material waste, boost productivity, and simplify operations.

Why Choose Our Automatic Rebar Bending Production Line?

- ✅ 20+ Years of R&D Excellence: Mature engineering team with ISO 9001-certified production.

- ✅ Customizable Workflows: Tailor bending angles, lengths, and speeds to match your project needs.

- ✅ 24/7 Global Support: On-site maintenance and ≤12-hour fault response (domestic).

- ✅ Energy-Saving Design: Up to 30% lower energy costs vs. hydraulic competitors.

- ✅ CE & ISO Compliance: Meets EU safety standards and global construction codes.

Key Features & Advantages

- Compact Design: Reduces tail material loss by 15% with space-saving engineering.

- Servo-Driven Precision: ±1mm feeding accuracy and ±0.5° bending angle control.

- High-Frequency Cutting: Servo blades process 60+ bars/minute for rapid project scaling.

- Planetary Reducer Tech: Durable torque transmission with 50,000-hour service life.

- IoT-Ready: Optional real-time monitoring via Yongtuo SmartControl software.

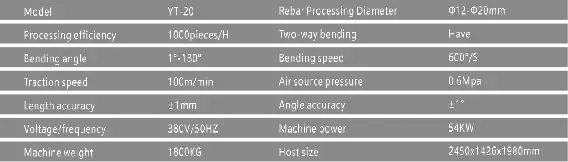

Technical Specifications

Applications

Our Automatic Rebar Bending Production Line is ideal for:

- High-Rise Buildings: Rapid reinforcement cage fabrication.

- Bridge/Tunnel Projects: High-volume bending for curved rebar.

- Prefab Factories: Batch processing of staircases, beams, and columns.

- Road Construction: Custom stirrups and mesh panels.

Customization Options

- Material Compatibility: Carbon steel, stainless steel, or epoxy-coated rebar.

- Software Integration: BIM/ERP compatibility for seamless data transfer.

- Automation Upgrades: Robotic arms for loading/unloading.

Certifications

- ISO 9001:2015 (Quality Management)

- CE Certification (EU Machinery Directive)

- GB/T 5226.1-2019 (Chinese Electrical Safety)

After-Sales Service

- Free Training: On-site operator training and maintenance workshops.

- Spare Parts Guarantee: 98% availability within 48 hours.

- Remote Diagnostics: Instant troubleshooting via Yongtuo Cloud.

Packaging & Shipping

Our Automatic Rebar Bending production line are meticulously prepared for safe global delivery. Each machine is first carefully wrapped in a high - quality anti - rust film. This film acts as a protective shield, preventing any exposure to moisture or corrosive elements that could lead to rust formation during transit. Subsequently, it is placed within a reinforced wooden frame. The wooden frame is constructed with thick, sturdy lumber and reinforced corners to withstand the rigors of handling, loading, unloading, and long - distance transportation. This combination of anti - rust film and a robust wooden frame ensures that our machines reach customers worldwide in perfect working condition, no matter how far they need to travel. Whether it's a small - scale business in a remote location or a large industrial enterprise, our shipping methods guarantee the safe arrival of their new equipment.

About Shaanxi Yongtuo

Established in 2003, our company has built an extensive global footprint by serving over 1,200 clients across 30 countries. Prominent names like Sinohydro and China Railway Group are among our esteemed clientele, attesting to the quality of our services. Housed in a sprawling 50,000㎡ factory in Xi'an, we have harnessed the power of advanced technology. Our state - of - the - art CNC laser cutters offer unparalleled precision in material shaping, while the AI - driven assembly lines optimize production efficiency. This blend of scale, clientele, and technological prowess enables us to consistently deliver top - notch products and solutions, meeting the diverse needs of industries worldwide.

Global Client Visits & Exhibitions

- 2023 Showcases: bauma CHINA, Middle East Concrete Dubai.

- Recent Projects: Thailand High-Speed Rail, Saudi NEOM City.

FAQ

Q: What's the ROI timeline for this Automatic Rebar Bending production line?

A: Most clients achieve payback in 14–18 months via labor cost savings.

Q: Can it process ribbed rebar?

A: Yes—our servo grippers handle ribbed, plain, or threaded bars.

Q: Do you provide installation?

A: Free installation and 3-day training included.

Q: How to request a quote?

A: Email specs to 13892319900@sxyongtuo.com for a <24-hour response.

Q: Is financing available?

A: Yes—we offer lease-to-own plans with 0% upfront.

Request Your Free Consultation Today!

📧 Email: sxyongtuo@gmail.com

Upgrade to Yongtuo's Automatic Rebar Bending Production Line—Where Precision Meets Profitability.

YOU MAY LIKE

_1744680888628.png)