2.Servo-controlled wire feeding and bending, with high precision in feeding length and bending angle.

3.Servo controlled cutting, high cutting frequency, can cut continuously at high frequency.

4.Wire feeding and bending adopt planetary reducer as torque transmission, which has high torque transmission efficiency, high precision and long service life.

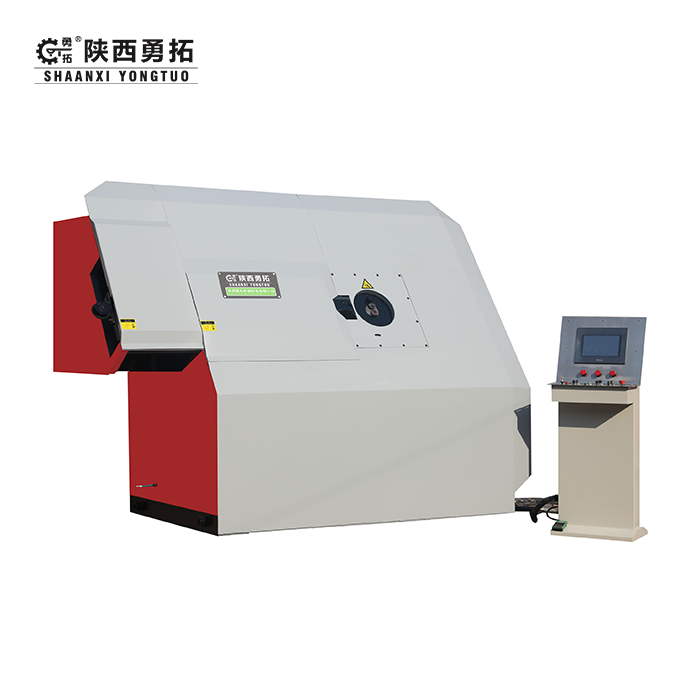

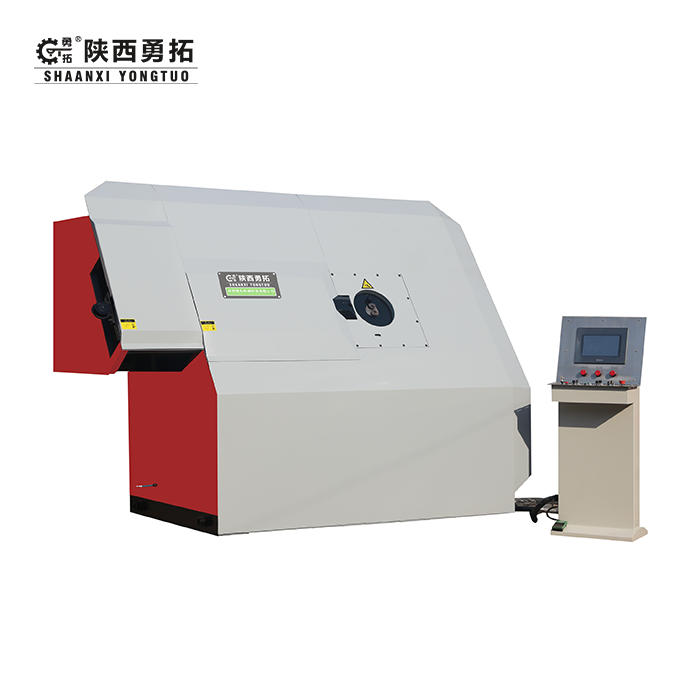

Shaanxi Yongtuo: Your Trusted Partner in Automated Steel Processing

Shaanxi Yongtuo Machinery Technology Co., Ltd, established in 2003, is a leading Fully Automated Steel Bar Bending Production Line manufacturer. With 37 patents, a mature R&D team, and a global client base, we deliver energy-saving, precision-engineered solutions trusted by construction giants and prefab factories worldwide.

Why Choose Us?

- ✅ Advanced Technology: Servo-controlled systems ensure ±0.5° bending accuracy.

- ✅ Proven Reliability: 10+ years of export experience with ≤0.5% failure rate.

- ✅ Cost Efficiency: Compact design reduces material waste by 15%.

- ✅ 24/7 Support: On-site maintenance within 12 hours (domestic).

- ✅ Customization: Tailor bending speed, length, and software integration.

Features & Advantages

- 🔹 Precision Control: Servo-driven feeding, bending, and cutting systems eliminate human error.

- 🔹 High Torque Transmission: Planetary reducers ensure 98% efficiency and 50,000-hour lifespan.

- 🔹 Energy Savings: 30% lower power consumption vs. traditional machines.

- 🔹 IoT-Ready: Remote monitoring via PLC interface for real-time data tracking.

- 🔹 Space-Saving: Modular design fits tight factory layouts.

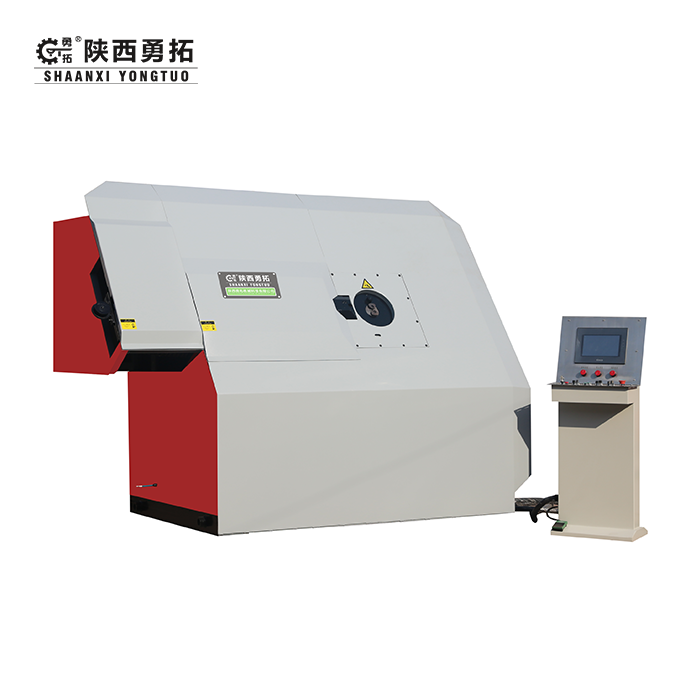

Product Parameters

|

Product Details

Our automated steel bar processing line integrates feeding, bending, and sorting into one seamless workflow. The planetary reducer-driven torque system ensures consistent performance under heavy loads. Download our 3D structure diagram [here] for a detailed view.

Application Areas

- 🏗️ Large-Scale Construction: Highways, bridges, and metro projects requiring ISO-compliant precision.

- 🏭 Prefab Factories: Batch production of reinforced concrete components.

- 🌍 International Projects: Machines adapted for tropical climates (anti-corrosion coating).

Customization Options

- Adjust bending angles (0–180°).

- Add RFID tags for material tracking.

- Upgrade to multi-language control panels.

Certifications

- ✔️ ISO 9001, CE, and SGS certified.

- ✔️ Compliant with GB/T 5226.1-2019 safety standards.

After-Sales Service

- 24-hour remote diagnosis.

- Free operator training (on-site or video).

- Lifetime technical support.

Packaging

Waterproof wooden crates with shock-absorbent foam. Export-ready with laser-printed labels.

Company Introduction

With 20+ years in steel processing machinery, Yongtuo has supplied equipment for the Beijing Daxing Airport and Malaysia's East Coast Rail Link.

Our Factory

Over 500 global clients, with industry powerhouses like China Railway Group and Saudi Binladin prominently among them, have conducted in - depth audits of our facilities. During these audits, they scrupulously examined every aspect of our operations, from the precision of our manufacturing equipment to the effectiveness of our quality management systems. Their scrutiny was not just a formality; it was a detailed assessment aimed at ensuring our products and services meet their exacting standards. Their presence in our facilities, and subsequent approval, is a strong endorsement of our commitment to delivering world - class solutions, further validating our position as a trusted partner in the global marketplace.

Customer Visits

Our clients meticulously review our manufacturing processes, quality control measures, and safety protocols. Their positive feedback and continued patronage not only highlight the reliability of our products and services but also fuel our drive to continuously improve and innovate, ensuring we remain at the forefront of meeting the evolving needs of the global market.

Exhibitions

Our experts will be present at each event to answer your questions, conduct product demonstrations, and explore potential partnerships. Don’t miss this opportunity to interact with us and learn how our Fully Automated Steel Bar Bending production line can revolutionize your project.

FAQ

Q: How long is the Fully Automated Steel Bar Bending production line delivery time?

A: 30–45 days after deposit.

Q: Can it process ribbed steel bars?

A: Yes, with custom-grooved rollers.

Q: What's the warranty period?

A: 2 years for core components.

Q: Do you provide Fully Automated Steel Bar Bending production line spare parts?

A: Yes – global express shipping available.

Q: How to reduce material waste?

A: Optimize cutting sequences via our YT-Smart V3.0 software.

Contact Us

📞 Call: +86 18392820056

📧 Email:sxyongtuo@gmail.com

Upgrade to Yongtuo's Fully Automated Steel Bar Bending Production Line Today – Precision, Efficiency, and Trust in Every Bend!

YOU MAY LIKE

_1744680888628.png)

_1760057043461.webp)