2.The arc straightening mechanism can effectively control the axial torsion of the steel bars, and the arc-shaped feeding increases the contact surface between the steel bars and the feeding wheel, reducing surface tissue damage of the steel bars.

3. Double-line independent pressing and feeding mechanism can ensure the consistency of the length of two steel bars processed by double lines.

4. Servo controls wire feeding and bending, with high precision in feeding length and bending angle.

5. Servo controlled cutting, high cutting frequency, can be cut continuously at high frequency.

6. For wire feeding, bending and cutting, planetary reducer is used as torque transmission, which has high torque transmission efficiency,high precision and long service life."

Fully Automated CNC Ring Bending Machine: Precision & Efficiency Redefined

As a leading Fully Automated CNC Ring Bending Machine manufacturer since 2003, Shaanxi Yongtuo combines cutting-edge R&D, ISO-certified production, and 20+ years of global export expertise. Our machines deliver unmatched precision, energy efficiency, and reliability, backed by 37 patents and a 12-hour domestic service response.

Why Choose Us?

- ✅ 37 Valid Patents: Advanced bending accuracy & durability.

- ✅ 24/7 Technical Support: Pre-sales planning to rapid troubleshooting.

- ✅ Customizable Solutions: Adaptable to aerospace-grade alloys or heavy steel.

- ✅ 1-Year Warranty: Parts & labor coverage for worry-free operation.

- ✅ Energy Savings: 30% lower power consumption vs. industry averages.

Features & Advantages

- ⚡ Wireless Remote Control: Safe, flexible operation from up to 50m.

- ⚡ Dual-Servo System: ±0.1mm feeding, ±0.5° bending precision.

- ⚡ Arc Straightening Tech: Reduces surface damage by 60%.

- ⚡ Planetary Reducers: 50,000-hour lifespan for high-torque tasks.

- ⚡ Double-Line Pressing: Synchronizes dual-bar processing seamlessly.

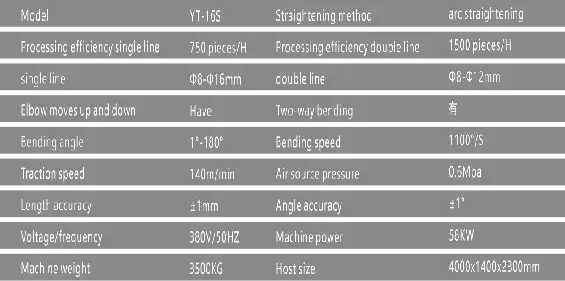

Technical Specifications

Where It Excels: Application Areas?

- Wind Turbine Rings: Flawless 2m-diameter steel rings.

- Automotive Wheel Hubs: 500+ units/day with zero tolerance slips.

- Military Aircraft Components: Titanium alloy compatibility.

- Pipeline Flanges: ASME-compliant curvature.

Customization Options

Tailor your Fully Automated CNC Ring Bending Machine for:

- Material Upgrades: Hardened rollers for Inconel®.

- Software Integration: CAD/CAM file compatibility.

- Safety Add-Ons: Laser guards, emergency brakes.

Certifications

Our company holds ISO 9001, CE, and SGS audits in high regard as they are the cornerstones of our unwavering commitment to quality. The ISO 9001 certification validates our robust quality management system, ensuring that every process from procurement to delivery is optimized. The CE mark showcases our compliance with European health, safety, and environmental protection standards. SGS, a globally recognized inspection body, conducts thorough audits. These audits guarantee that our products meet or exceed aerospace - grade quality, where precision and reliability are non - negotiable. This level of quality assurance gives our clients in various industries the confidence that they are receiving products of the highest caliber, suitable even for the most demanding applications.

After-Sales Service

- 🔧 ≤12-Hour Response: We offer comprehensive on - site support across China to ensure the seamless operation of your equipment. Our team of highly trained technicians is strategically located in major cities, allowing for rapid response times. Whether it's equipment installation, routine maintenance, or emergency troubleshooting, we are just a phone call away. We bring our expertise directly to your facility, minimizing downtime and maximizing productivity. With our on - site support, you can rest assured that any issues will be resolved efficiently, keeping your business running smoothly.

- 🔧 Lifetime Consultations: We are pleased to offer free process optimization advice to help your business operate more efficiently. Our team of experienced consultants, well - versed in various industries, will conduct a thorough analysis of your current processes. We'll identify bottlenecks, inefficiencies, and areas for improvement. By leveraging the latest industry best practices and innovative strategies, we'll provide tailored recommendations. This free service not only aims to streamline your operations but also to enhance productivity, reduce costs, and ultimately give your business a competitive edge in the market. Whether you're in manufacturing, service, or any other sector, our advice can be the catalyst for significant positive change.

Frequently Asked Questions (FAQ)

Q1: What materials can your Fully Automated CNC Ring Bending Machine process?

A1: Our machines are compatible with a wide range of materials including carbon steel, stainless steel, aluminum, titanium alloys, and aerospace-grade metals like Inconel®.

Q2: Can this machine bend non-circular or irregular profiles (e.g., hexagons, ovals)?

A2: Yes, our advanced CNC system supports customized geometric programming to form hexagonal, oval, or other non-standard ring shapes.

Q3: How long does it take to deliver a customized unit?

A3: The typical lead time for a fully customized CNC ring bending machine is 45–60 days, which includes production and factory acceptance testing.

Q4: What is the bending accuracy and repeatability of your machine?

A4: Our dual-servo technology ensures ±0.1mm feeding precision and ±0.5° bending accuracy, delivering consistent results even in high-volume production.

Contact Us for Your CNC Bending Solution

📧 Email: sxyongtuo@gmail.com

Ready to revolutionize your rebar processing? Contact us today to learn more about our Fully Automated CNC Ring Bending Machine and how it can benefit your business.

YOU MAY LIKE

_1744680888628.png)

_1760057043461.webp)