2.The double-line independent pressing and feeding mechanism can ensure the consistency of the length of the two steel bars during double-line processing.

3. Servo controls wire feeding and bending, with high precision in feeding length and bending angle.

4.Servo controlled cutting, high cutting frequency, can cut continuously at high frequency

5. For wire feeding, bending and cutting, planetary reducer is used as torque transmission, which has high torque transmission efficiency, high precision and long service life.

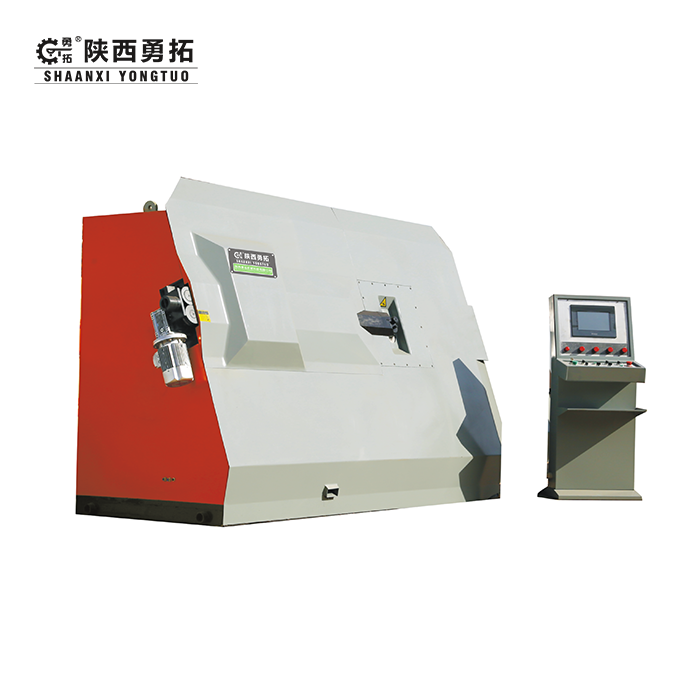

Automatic Stirrup Benders: Precision Engineering for Modern Construction

Shaanxi Yongtuo Machinery Technology Co., Ltd, established in 2003, is a leading manufacturer and supplier of Automatic Stirrup Benders, trusted globally for innovative steel bar processing solutions. With 37 patents, a mature R&D team, and a professional after-sales network, we deliver energy-saving, reliable machines designed to streamline your operations.

Why Choose Us?

- ✅ 20+ Years Expertise: Trusted by construction giants and steel factories worldwide.

- ✅ 37 Valid Patents: Advanced CNC technology ensures precision and durability.

- ✅ 24/7 Support: On-site maintenance within ≤12 hours (domestic).

- ✅ Global Compliance: CE, ISO certifications meet international standards.

- ✅ Custom Solutions: Tailor machines to your project's unique needs.

Features & Advantages

- Arc-Shaped Straightening Mechanism: Reduces steel bar surface damage and axial torsion.

- Dual-Line Pressing System: Ensures consistent length for parallel processing.

- Servo-Controlled Precision: ±1mm accuracy in feeding and ±0.5° in bending.

- High-Frequency Cutting: Servo-driven blades for 60 cuts/minute efficiency.

- Planetary Reducer: Enhances torque transmission, extending lifespan.

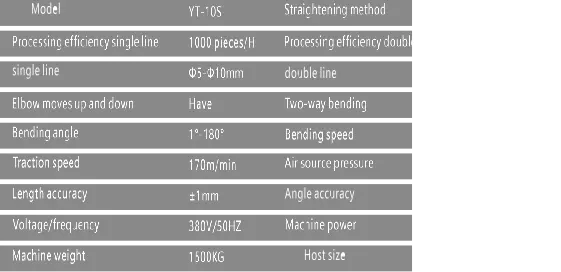

Product Parameters

Product Details

Our Automatic stirrup benders features a robust modular design with an intuitive touchscreen interface. The arc-shaped feeding mechanism minimizes steel bar wear, while servo motors ensure repeatable accuracy.

Application Areas

- High-rise buildings & bridges requiring earthquake-resistant stirrups.

- Railway tunnels, highways, and hydropower projects.

- Prefabricated construction component factories.

Customization Options

- Adjust bending angles (30°-180°).

- Modify feeding lengths (100mm-2,000mm).

- Multi-language interfaces (English, Arabic, Spanish).

Certifications

- CE, ISO 9001, and SGS certified.

- Compliant with GB/T 19001-2016 quality standards.

After-Sales Service

- 24/7 remote troubleshooting.

- Free operator training and 1-year warranty.

- Spare parts delivered within 48 hours.

Packaging

Our export - ready wooden crates, designed to meet the rigors of international shipping, are equipped with a triple - layer protection system. A high - grade waterproof film, impervious to moisture, safeguards your cargo from water damage during transit. Additionally, shock - absorbent foam lines the interior. This foam cushions the items, reducing the impact of jolts and vibrations that may occur during handling or transportation. Whether your goods are delicate electronics, fine art pieces, or precision - engineered components, our crates provide the reliable protection necessary for a safe journey across the globe. They are meticulously constructed to ensure that your valuable items arrive at their destination in pristine condition, giving you peace of mind throughout the export process.

Company Introduction

Based in Shaanxi, China, Yongtuo stands as a paragon of innovation and efficiency. With over 20 years of dedicated R&D, we have continuously refined our technologies and products. Our 15,000㎡ smart factory is a hub of advanced manufacturing, equipped with cutting - edge automation and precision - driven machinery. This enables us to produce high - quality items at scale. Leveraging our expertise and state - of - the - art facilities, we have successfully served clients in 50+ countries. Whether it's providing customized solutions or meeting large - volume orders, Yongtuo has built a reputation for reliability and excellence on the global stage.

Our Factory

Equipped with 6 automated production lines, our manufacturing facility operates at an impressive pace, enabling us to produce 500+ machines annually. These state - of - the - art lines are staffed by a team of highly skilled technicians who ensure seamless operations. Each machine undergoes rigorous quality checks at multiple stages of production. From raw material inspection to final product testing, we adhere to strict international standards. Our in - house quality control department uses advanced diagnostic tools and techniques to verify performance, durability, and safety. This commitment to quality not only guarantees that our customers receive top - notch products but also reinforces our position as a leading manufacturer in the industry.

Customer Visits

Clients like China Railway Group and Larsen & Toubro have toured our facility, praising our scalable solutions.

Exhibitions

Spot us at Bauma China, Intermat Paris, and bC India for live demos.

FAQ

Q: What's the ROI of your Automatic Stirrup Benders?

A: Most clients recover costs in 8-12 months via 70% labor savings.

Q: Can it process irregular shapes?

A: Yes! Custom programming handles trapezoidal or polygonal stirrups.

Q: How to handle maintenance?

A: Our app provides real-time diagnostics; local agents assist promptly.

Q: Are your machines energy-efficient?

A: Yes! 30% lower energy use vs. hydraulic competitors.

Q: Lead time for orders?

A: 15-30 days, depending on customization.

Contact Us

Boost productivity with Yongtuo's Automatic Stirrup Benders!

Optimized for durability, precision, and scalability, Yongtuo's product redefine efficiency in steel bar processing. Let's build the future, together.

YOU MAY LIKE

_1744680888628.png)

_1760057043461.webp)