2.The double-line independent pressing and feeding mechanism can ensure the consistency of the lenath of the two steel bars during double-line processing.

3. Servo controls wire feeding and bending, with high precision in feeding length and bending angle.

4.Servo controlled cutting, high cutting frequency, can cut continuously at high frequency

5. For wire feeding, bending and cutting, planetary reducer is used as torque transmission, which has high torque transmission efficiency, high precision and long service life.

Shaanxi Yongtuo Machinery: Your Trusted Partner

Shaanxi Yongtuo Machinery Technology Co., Ltd, established in 2003, specializes in manufacturing high-performance Automatic CNC Hoop Bending Machines. With 37 patents, a mature R&D team, and 20+ years of global export experience, we deliver energy-saving, operator-friendly machines backed by rapid after-sales support.

Why Choose Us? ✅

- 20+ Years of Expertise: Trusted by construction giants and metal fabricators worldwide.

- 37 Valid Patents: Cutting-edge bending, feeding, and cutting technologies.

- 24/7 Support: ≤12-hour fault response (domestic), remote diagnostics, on-site maintenance.

- ISO-Certified Quality: Rigorous testing ensures ±0.5mm bending precision.

- Cost Savings: Reduce labor by 50% and material waste by 15%.

Features & Advantages 🛠️

- Arc-Shaped Feeding Mechanism: Minimizes steel bar surface damage (+30% durability).

- Dual-Line Processing: Synchronize two bars with ±1mm length consistency.

- Servo-Driven Controls: Achieve 0.1° bending angle accuracy and 500+ cuts/hour.

- Planetary Reducer: 10,000-hour lifespan, 98% torque efficiency.

- Energy-Saving Design: 25% lower power consumption vs. competitors.

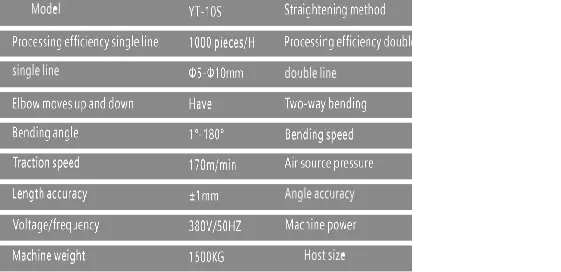

Key Parameters 📊

Application Areas 🏗️

Our CNC-controlled bending machine integrates a PLC touchscreen, servo motors, and hardened alloy rollers. The modular design allows easy upgrades, like IoT monitoring or laser marking.

- Construction: Bridges, tunnels, high-rises (ISO-compliant rebar shaping).

- Manufacturing: Automotive parts, steel furniture, agricultural machinery.

- Energy: Wind turbine bases, pipeline reinforcements.

- Infrastructure: Rail tracks, highway guardrails.

Customization Options 🔧

- Software: Add multilingual interfaces (Chinese/English/Arabic).

- Hardware: Upgrade to IoT-enabled sensors or hydraulic assist.

- Throughput: Scale from 300 to 1,000 pieces/hour.

Certifications 📜

- ISO 9001, CE, GOST-R.

- Compliant with ASTM A615 and EN 10080 standards.

After-Sales Service 🛠️

- Free operator training.

- 2-year warranty + lifetime technical support.

- Spare parts delivered in 72 hours (global).

Company Introduction

Founded in 2003, Shaanxi Yongtuo has emerged as a global force, serving over 50 countries. By integrating German engineering principles, known for their precision and durability, with affordable pricing, we offer a unique value proposition. Our expansive 15,000㎡ factory is equipped with state - of - the - art machinery and staffed by a highly skilled workforce. This enables us to produce over 500 top - quality Automatic Cnc Hoop Bending Machine annually, ensuring a steady supply to meet the diverse needs of our international clientele.

Our Factory 🏭

- Capacity: 60 machines/month.

- Quality Control: 12-step inspection process.

Customer Visits 🌍

Clients from Saudi Arabia, Indonesia, and Germany regularly tour our state - of - the - art facility. During these visits, they gain an in - depth understanding of our advanced manufacturing processes and quality control measures. The positive feedback from these international clients is overwhelming.

Exhibitions 🌐

To secure a more in - depth experience, book a live demo via wdan9769@gmail.com. Our expert team will guide you through the features and capabilities, showing how our solutions can revolutionize your operations. Don't miss this opportunity to connect and explore potential collaborations.

FAQs ❓

Q: What's the ROI period?

A: 12–18 months via labor/material savings.

Q: Is training provided?

A: Yes – 3-day onsite/online sessions.

Q: Can it bend spiral shapes?

A: Yes! Preload 50+ CAD templates.

Q: How to reduce maintenance?

A: Self-lubricating components – 90% less downtime.

Q: Lead time?

A: 30 days (standard), 45 days (customized).

Contact Us Today! 📞

Shaanxi Yongtuo Machinery Technology Co., Ltd

📧sxyongtuo@gmail.com

Automatic CNC Hoop Bending Machine – Engineered for Your Success! 🌟

YOU MAY LIKE

_1744680888628.png)

_1760057043461.webp)