2.The bending rotation speed can be set arbitrarily, providing greater processing flexibility.

3.A planetary reducer is used for torque transmission during bending, resulting in low noise, high precision, and long service life.

4.The middle clamping system uses a multi-piece flexible clamp, effectively securing multiple rebars and ensuring consistency in the dimensions of all processed rebars."

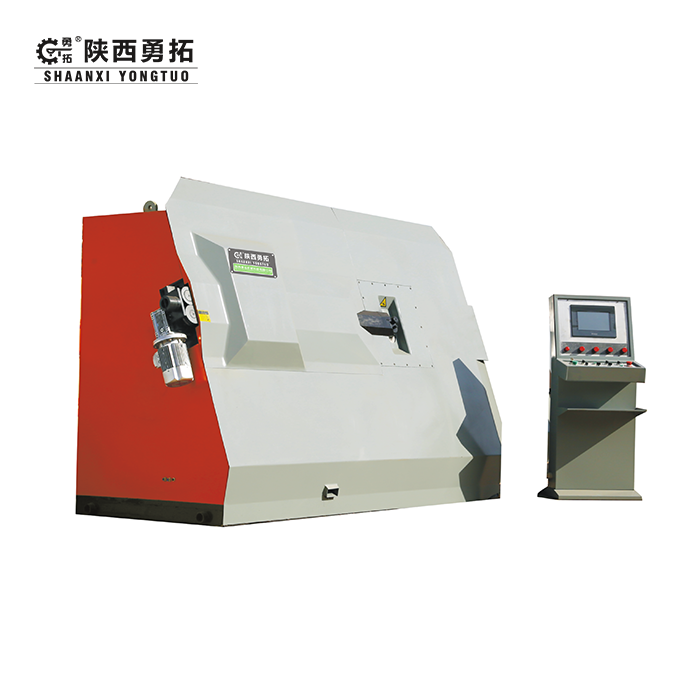

Shaanxi Yongtuo: Your Trusted CNC Vertical Bending Production Line Partner

Shaanxi Yongtuo Machinery Technology Co., Ltd is a leading CNC Vertical Bending Production Line manufacturer and supplier with 20+ years of expertise. Our fully automated systems combine advanced servo technology, energy-saving designs, and ISO-certified quality to deliver unmatched precision (±0.1mm) for industries like automotive, aerospace, and construction.

Why Choose Us?

✅ 20+ Years of R&D Excellence: Mature engineering team with 37 patents.

✅ End-to-End Support: Pre-sales planning, onsite training, and 24/7 multilingual after-sales service.

✅ Global Compliance: CE, ISO 9001, and RoHS certifications.

✅ Cost Efficiency: 30% energy savings vs. conventional machines.

✅ Rapid Response: ≤12-hour fault diagnosis, 72-hour spare parts delivery.

Key Features & Advantages

✔️ Servo-Controlled Precision: Dual-axis servo motors ensure ±0.1° bending angle accuracy.

✔️ Flexible Speed Settings: Adjust rotation speeds (5-60 RPM) for diverse materials like stainless steel or titanium.

✔️ Planetary Reducer Tech: Noise <65 dB, 50,000-hour lifespan.

✔️ Multi-Piece Clamping System: Secure up to 12 rebars simultaneously with zero slippage.

✔️ IoT-Ready: Real-time monitoring via YT-SmartControl software.

Technical Parameters

Application Areas

Our CNC Vertical Bending Production Line is ideal for:

- Automotive: Exhaust pipes, chassis components.

- Aerospace: Hydraulic tubes, engine mounts.

- Construction: Steel frames, curtain wall supports.

- Energy: Wind turbine flanges, oil pipelines.

Customization Options

Tailor your system with:

- Material-specific tooling (stainless steel, aluminum).

- Integration with robotic arms or MES software.

- Voltage customization (220V–480V).

Certifications

All machines meet CE, ISO 9001, and RoHS standards. We also comply with automotive IATF 16949 and aerospace AS9100 requirements.

After-Sales Service

- 24/7 Remote Support: Connect via email/WhatsApp (+86 13892319900).

- Onsite Maintenance: Global technicians available.

- Warranty: 2-year coverage on critical components.

Packaging & Shipping

Before shipment, our CNC Vertical Bending production line are carefully disassembled into shock - proof crates. Each component undergoes a meticulous anti - rust treatment to ensure long - term durability, even during extended transportation. This process involves applying a specialized anti - rust coating that guards against corrosion from moisture and environmental factors.

For shipping, we offer both air and ocean freight options to meet your time and budget requirements. Our door - to - door tracking service provides you with real - time updates on the location of your shipment. Using advanced tracking technology, you can monitor your machines' journey from our facility to your doorstep, giving you complete peace of mind throughout the entire process.

Company Introduction

Established in 2003, Shaanxi Yongtuo has been steadily expanding its global footprint, proudly serving clients in over 50 countries. Our 12,000㎡ factory in Xi'an is a remarkable blend of German engineering precision and Chinese manufacturing efficiency. By integrating German - designed technologies and production standards, we ensure the highest quality output. Meanwhile, our Chinese - based manufacturing prowess allows for cost - effective production and rapid turnaround times. This unique combination enables us to offer innovative, reliable products at competitive prices, meeting the diverse needs of our international clientele.

Customer Visits & Exhibitions

At Shaanxi Yongtuo Machinery, we warmly welcome global partners to visit our manufacturing facility in Xi'an. Over the years, we’ve hosted hundreds of customers from more than 30 countries, offering them in-depth factory tours, live equipment demonstrations, and technical discussions. These visits not only showcase our advanced production capabilities and quality control standards but also foster long-term cooperation and mutual trust.

FAQs

Q: Can this CNC Vertical Bending production line bend square tubes?

A: Yes—customized tooling handles round, square, and hexagonal profiles with precision.

Q: What’s the typical lead time?

A: 30–45 days after receiving the deposit and confirming specifications.

Q: Is CAD/CAM software supported?

A: Absolutely. Our system integrates seamlessly with AutoCAD, SolidWorks, and our in-house YT-BendDesigner platform.

Q: How can I reduce setup time?

A: Our automatic tool-change system reduces setup time to under 5 minutes.

Q: What’s the expected return on investment?

A: Most clients achieve ROI within 18 months through labor savings and reduced material waste.

Contact Us

Ready to upgrade your bending process?

📧 Email: sxyongtuo@gmail.com

Shaanxi Yongtuo Machinery – Precision CNC Vertical Bending Production Line Solutions for Tomorrow's Manufacturing Challenges.

YOU MAY LIKE

_1744680888628.png)