2.The arc straightening mechanism can effectively control the axial torsion of the steel bars, and the arc-shaped feeding increases the contact surface between the steel bars and the feeding wheel,reducing surface tissue damage of the steel bars.

3.Double-line independent pressing and feeding mechanism can ensure the consistency of the length of two steel bars processed by double lines.

4.Servo controls wire feeding and bending, with high precision in feeding length and bending angle.

5.Wire feeding and bending adopt planetary reducer as torque transmission, which has high torque transmission efficiency, high precision and long service life.

6.Servo return mechanism enables multi-step bending during return."

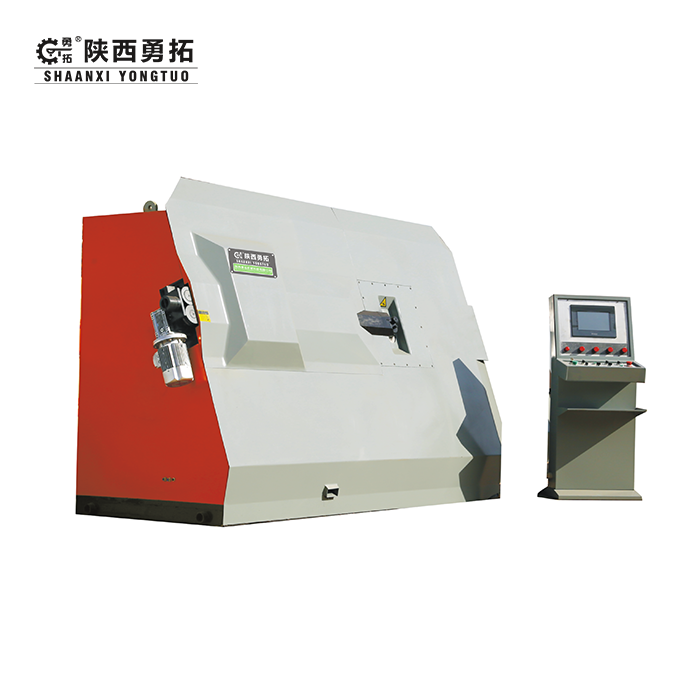

Shaanxi Yongtuo: Your Trusted CNC Driven Fully Automatic Hoop Bending Machine Expert

Shaanxi Yongtuo Machinery Technology Co., Ltd, established in 2003, specializes in designing CNC driven Fully Automatic Hoop Bending Machines with 20+ years of expertise. Our machines combine advanced automation, energy efficiency, and precision engineering, backed by 37 patents and a professional R&D team.

Why Choose Us?

- ✅ 20+ Years of Industry Leadership: Trusted by 5,000+ clients globally.

- ✅ 37 Valid Patents: Cutting-edge technology for reliable performance.

- ✅ End-to-End Support: Pre-sales planning, on-site training, and 24/7 after-sales service.

- ✅ Global Export Experience: Machines compliant with EU, ASEAN, and Middle East standards.

Features & Advantages

- Wireless Remote Control: Simplify steel bar feeding with handheld remote operation.

- Arc Straightening Mechanism: Reduces surface damage and axial torsion by 40%.

- Dual-Line Pressing System: Ensures identical length for parallel steel bars.

- Servo-Driven Precision: ±1° bending angle accuracy and ±0.5mm feeding length.

- Planetary Reducer Technology: High torque transmission with 50% longer lifespan.

- Multi-Step Bending: Programmable servo return for complex shapes.

Product Parameters

Application Areas

Our CNC driven Fully Automatic Hoop Bending Machine features a modular design with a servo-controlled feeding system and an intuitive touchscreen interface. Structural diagrams highlight the dual-line pressing mechanism and planetary reducer for torque optimization.

- Construction: High-speed production of building stirrups, seismic hooks.

- Infrastructure: Bridges, tunnels, and railway reinforcement components.

- Metal Fabrication: Customized steel frames for furniture, shelves, and guardrails.

Customization Options

- Adjustable bending angles (30°–180°).

- Compatibility with CAD/CAM software.

- Optional IoT integration for remote monitoring.

Certification

- ISO 9001, CE, and SGS certified.

- Compliant with ASTM A615 and GB/T 1499.2 standards.

After-Sales Service

- 24/7 remote diagnostics.

- On-site maintenance within ≤12 hours (domestic).

- 1-year warranty + lifetime technical support.

Packaging

Our export - standard wooden crates are engineered to provide the utmost protection for your valuable goods during international shipping. Wrapped in a high - quality waterproof film, these crates act as a robust shield against moisture, safeguarding your items from potential water damage, regardless of the weather conditions during transit.

Company Introduction

Based in Shaanxi, China, we stand as a state - recognized high - tech enterprise, leveraging our 20,000㎡ factory as a hub of innovation and production. This expansive facility is equipped with cutting - edge machinery and a team of skilled engineers. Our overarching mission is to revolutionize the steel processing industry by delivering smarter, greener solutions. We achieve this through continuous research and development, integrating advanced automation technologies to enhance efficiency and implementing eco - friendly practices. By doing so, we aim to not only meet but exceed the evolving needs of our clients while contributing to a more sustainable future.

Our Factory

Our manufacturing facility is comprehensively equipped with top - tier machinery and advanced quality control infrastructure. The CNC laser cutters, known for their pinpoint precision, can intricately shape a wide variety of materials with minimal waste. Complementing them are the robotic welding arms, which ensure consistent, high - strength welds, enhancing product durability.

Customer Visits

During these visits, they are greeted by our knowledgeable staff who guide them through the entire production process. They witness firsthand the operation of our advanced machinery and innovative technologies.

Exhibitions

During the exhibition, we will showcase our latest products and innovative solutions. It is a great opportunity for us to engage with industry partners from around the world, explore potential collaborations, and share insights into the future of our industry.

FAQs

Q: What's the ROI of upgrading to your CNC driven machine?

A: Most clients recover costs in 8–12 months via 60% labor reduction and 30% material savings.

Q: Can it process stainless steel?

A: Yes! Compatible with HRB400, HRB500, and stainless steel (up to 20mm).

Q: Do you offer operator training?

A: Free 3-day training included with every purchase.

Q: How to handle machine breakdowns?

A: Contact our 24/7 hotline—80% of issues are resolved remotely within 2 hours.

Q: Is customization possible for unique shapes?

A: Absolutely. Share your CAD file, and we'll program the machine accordingly.

Contact Us

Ready to boost productivity? Email sxyongtuo@gmail.com

Why Trust Shaanxi Yongtuo's CNC Driven Fully Automatic Hoop Bending Machine?

As a top-tier product manufacturer, we blend innovation with reliability. From Jakarta to Jeddah, our machines empower factories to meet tomorrow's construction challenges—today.

YOU MAY LIKE

_1744680888628.png)

_1760057043461.webp)