2.The double-line independent pressing and feeding mechanism can ensure the consistency of the lenath of the two steel bars during double-line processing.

3. Servo controls wire feeding and bending, with high precision in feeding length and bending angle.

4.Servo controlled cutting, high cutting frequency, can cut continuously at high frequency

5. For wire feeding, bending and cutting, planetary reducer is used as torque transmission, which has high torque transmission efficiency, high precision and long service life.

Manufacturer & Supplier | Shaanxi Yongtuo Machinery Technology Co., Ltd

For over 20 years, Shaanxi Yongtuo Machinery Technology Co., Ltd has delivered high - precision, energy - efficient Fully Automatic CNC Steel Bar Bending Machines trusted by construction, metalworking, and energy industries worldwide. Our machines stand out with advanced servo technology that enables precise and smooth bending operations. The patented designs optimize the machine's performance and functionality, ensuring it can handle various steel bar sizes and shapes with ease. Moreover, our ISO - certified manufacturing process adheres to the highest quality standards. This not only guarantees top - notch products but also boosts productivity significantly, allowing our customers to complete projects faster. At the same time, by minimizing errors, our machines effectively reduce material waste, saving both costs and resources for our clients in different industries.

Why Choose Us?

- ✅ 20+ Years of Expertise: Original factory with 37 valid patents.

- ✅ Precision Engineering: ±0.5° bending accuracy for complex shapes.

- ✅ 24/7 After-Sales Support: ≤12-hour fault response, global service network.

- ✅ Energy Efficiency: 30% lower power consumption vs. competitors.

- ✅ Custom Solutions: Tailored for Ø6-40mm steel bars and IoT integration.

Key Features & Advantages

- Arc-Shaped Feeding System

Reduces steel bar surface damage and axial torsion with optimized contact. - Dual-Line Processing

Ensures consistent length (±1mm) for parallel steel bar production. - Servo-Driven Control

High-speed cutting (60 cycles/min) and 0.1° angle repeatability. - Planetary Reducer Technology

Enhances torque transmission efficiency and extends lifespan by 50%.

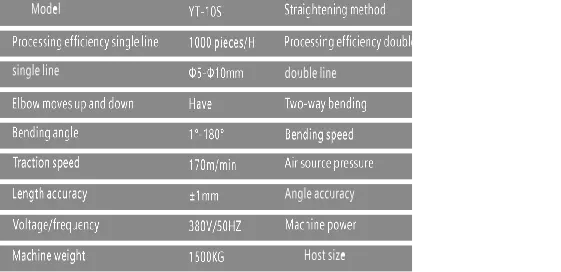

Technical Parameters

Applications

- Construction: Bridges, high-rise buildings, prefab components.

- Renewable Energy: Wind turbine bases, solar farm structures.

- Automotive: Chassis frames, reinforcement parts.

- Railways: Track components, tunnel support systems.

Customization & Certifications

- Custom Mold Designs: For U-shaped, spiral, or threaded bars.

- Software Integration: Compatible with AutoCAD, Tekla, and SolidWorks.

- Certifications: ISO 9001, CE, and GOST-R compliance.

After-Sales Service

- Our 24/7 remote diagnostics ensure real-time monitoring and swift issue resolution, minimizing downtime for your projects worldwide. With ≤12-hour on-site support for domestic clients, our expert technicians deliver rapid, reliable assistance to keep operations running smoothly. Backed by cutting-edge technology and a dedicated global service network, we provide unparalleled support, ensuring your equipment performs at peak efficiency, no matter the location or challenge. Trust us to keep your projects on track with seamless, round-the-clock service.

- Free operator training and 2-year warranty on critical components are provided to ensure seamless operations and long-term reliability. Our professional trainers will conduct in-depth sessions, covering all aspects of equipment usage and troubleshooting. The 2-year warranty on key parts, such as engines and control panels, guarantees that in case of any malfunctions during this period, we will promptly replace or repair them at no extra cost, giving you peace of mind.

Exhibitions

Shaanxi Yongtuo Machinery Technology Co., Ltd is committed to promoting Chinese smart manufacturing to the world. We participate in many large-scale international machinery and construction exhibitions every year, communicate face-to-face with global customers, and showcase the latest automated steel bar processing technologies and innovative achievements.

Customer Visits

We sincerely welcome partners from all over the world to visit and experience the intelligent, standardized, and globalized manufacturing process. We will provide you with:

- Free pick-up and drop-off service

- Professional technicians explain the whole process

- Personalized project demonstration and customized solution suggestions

FAQ

Q: Can this machine process stainless steel bars?

A: Yes! Adjustable pressure settings support stainless steel, carbon steel, and rebar.

Q: How long does installation take?

A: Our team completes setup in 3-5 days, including calibration and training.

Q: How do I request spare parts?

A: Email sxyongtuo@gmail.com with your machine ID for fast global shipping.

Upgrade to Precision – Contact Us Today!

Shaanxi Yongtuo's Fully Automatic CNC Steel Bar Bending Machine is your partner for faster, smarter, and error-free production. Let's build the future together!

YOU MAY LIKE

_1744680888628.png)

_1760057043461.webp)