2.Servo-controlled length measurement ensures high precision and good consistency in material cutting.

3.200-ton shearing cylinder for high production efficiency.

4.Equipped with a scrap collection box for centralized collection of leftover material.

5.Double-sided, three-position finished product collection bin to accommodate centralized collection of various specifications.

6.The collection bin is equipped with a steel chain for collection, reducing noise during collection.

7.Optional automatic raw material loading device to reduce the labor intensity of loading work."

High-Efficiency Bar Cutting Production Line for Precision & Productivity

Shaanxi Yongtuo Machinery Technology Co., Ltd is a leading Bar Cutting Production Line manufacturer and supplier with 20+ years of expertise. Our advanced CNC technology, energy-saving designs, and ISO-certified quality ensure reliable, high-precision solutions for steel rebar and metal processing. the High-Efficiency Cutting Production Line—engineered to deliver ±0.05mm cutting precision, unmatched reliability, and scalable productivity.

Designed for demanding applications across construction, automotive, and precision manufacturing, this fully automated system combines servo-driven measurement, 200-ton shearing force, and intelligent IoT integration to minimize waste, reduce labor costs, and optimize throughput. Whether you’re cutting carbon steel, stainless steel, or special alloys, Yongtuo’s cutting solution guarantees clean, consistent results—every time.

Why Choose Us?

- ✅ 37 Patents & Mature R&D: Cutting-edge servo control systems for ±1mm precision.

- ✅ 24/7 After-Sales Support: ≤12-hour fault response, global spare parts network.

- ✅ Cost-Efficient Production: 200-ton shearing force reduces waste by 15%.

- ✅ 1,000+ Successful Installations: Trusted by Fortune 500 construction firms.

- ✅ Customizable Workflows: Adapt to materials from Φ6mm to Φ40mm.

Key Features & Advantages

- High-Speed Servo Feeding: 0.5-second measurement for 60 cuts/hour efficiency.

- Noise-Reduced Collection: Steel chain bins lower noise to <75dB.

- Scrap Recycling System: Centralized collection saves 10% material costs.

- Triple Safety Guards: Overload protection + emergency stop + IoT alerts.

- Energy-Saving Design: 30% lower power use vs. competitors.

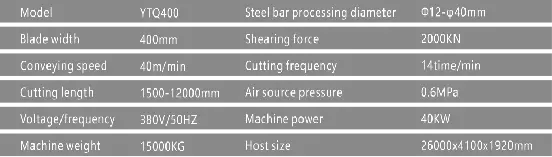

Technical Parameters

|

Application Areas

- 🏗️ Construction: High-speed rebar cutting for bridges, tunnels, and high-rises.

- 🔩 Automotive: Precision alloy bars for engine components.

- ⚡ Renewable Energy: Custom-length steel rods for wind turbine bases.

- 🏭 Metal Fabrication: Batch processing for HVAC and machinery parts.

Customization Options

- Length Adjustments: 3m–12m cutting range.

- Material Compatibility: Configure for stainless steel, copper, or titanium.

- Automation Upgrades: Add robotic arms or conveyor belts.

Certifications

Our Bar Cutting Production Line are backed by prestigious CE, ISO 9001, and SGS certifications. These accreditations validate our commitment to quality, safety, and international best practices. Moreover, we are fully compliant with OSHA safety standards, ensuring that every aspect of our manufacturing process prioritizes the well - being of our workers and the end - users of our products.

After-Sales Service

When you choose our products, we offer a comprehensive package that includes free onsite installation and operator training. Our skilled technicians will visit your site, set up the equipment precisely, and provide hands - on training to your operators, ensuring they can use the machinery effectively from day one. Additionally, we provide a generous 2 - year warranty, covering any potential manufacturing defects. And for the lifetime of the product, our technical support team is just a call away, ready to assist with any issues, upgrades, or questions you may have.

FAQs

Q: Can this line integrate with existing bending machines?

A: Yes! Our Bar Cutting Production Line systems sync seamlessly with Yongtuo's CNC benders.

Q: What's the lead time for customization?

A: 30–45 days, depending on specs.

Q: Do you provide overseas maintenance?

A: Absolutely. We have technicians in 15+ countries.

Q: How much floor space is required?

A: Minimum 6m x 4m. Download layout guides [here].

Q: Is raw material loading automated?

A: Optional robotic feeders are available.

Contact Us for Your Bar Cutting Production Line!

📧 Email: sxyongtuo@gmail.com

🏭 Visit: Our 20,000㎡ factory in Xi'an, China (Open Mon–Sat).

Why Trust Shaanxi Yongtuo?

- 🏆 37 patents, 500+ global clients.

- 🏆 2023 "Top 10 Construction Machinery Brands" awardee.

YOU MAY LIKE

_1744680888628.png)