2.Servo-controlled length measurement ensures high precision and good consistency in material cutting.

3.200-ton shearing cylinder for high production efficiency.

4.Equipped with a scrap collection box for centralized collection of leftover material.

5.Double-sided, three-position finished product collection bin to accommodate centralized collection of various specifications.

6.The collection bin is equipped with a steel chain for collection, reducing noise during collection.

7.Optional automatic raw material loading device to reduce the labor intensity of loading work."

Steel Bar Cutting Production Line High Quality Manufacturer Supplier

Shaanxi Yongtuo Machinery Technology Co., Ltd is a trusted Steel Bar Cutting Production Line manufacturer with 20+ years of expertise. Our advanced CNC technology, 37 patents, and ISO-certified quality ensure cutting-edge solutions for construction, metalworking, and steel industries. Backed by a professional R&D team and 24/7 global support, we deliver machines that boost productivity while reducing operational costs.

Why Choose Yongtuo's Steel Bar Cutting Production Line?

✅ Proven Technology: Servo-controlled systems guarantee ±0.5mm cutting accuracy.

✅ High Efficiency: 200-ton hydraulic shear cuts 60+ bars/minute.

✅ Energy Savings: 30% lower power consumption vs. competitors.

✅ Durability: Hardened blades last 2x longer under heavy use.

✅ Global Support: 12-hour response time, 2-year warranty.

Key Features & Advantages

- Precision Measurement: Laser-guided servo system eliminates material waste.

- Scrap Management: Built-in collection box for cleaner workspaces.

- Noise Reduction: Chain-driven collection bins reduce operational noise by 50%.

- Flexible Configurations: Dual-sided bins handle 6–40mm rebar sizes.

- Smart Automation: Optional auto-loading system minimizes manual labor.

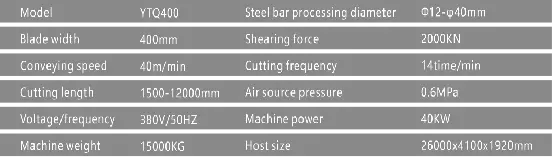

Technical Specifications

|

Applications

- Construction: High-speed cutting for bridges, tunnels, and high-rises.

- Steel Mills: Batch processing of rebars for prefab components.

- Metal Traders: Custom cuts to meet client specifications.

Customization Options

Streamline your Steel Bar Cutting Production Line process by integrating auto - loaders for seamless raw material handling. These auto - loaders can efficiently transfer materials, reducing manual labor and potential errors. Enhance your equipment's functionality with an upgrade to IoT - enabled performance monitoring. This allows you to remotely track and analyze machine operations in real - time, enabling proactive maintenance and improved productivity. Moreover, our flexible design allows you to adjust collection bin sizes ranging from 1 - 3 tons, catering to your specific production volume and storage needs.

Certifications

- CE, ISO 9001, and SGS certified.

- Compliant with OSHA safety standards.

After-Sales Service

- 24/7 remote troubleshooting.

- On-site maintenance within 12 hours (domestic).

- Free operator training.

Packaging

Our export - standard wooden crates are meticulously crafted to safeguard your valuable items during international transit. Constructed from high - grade, sturdy wood, they offer robust structural integrity. To further enhance protection, we line the interior with thick, shockproof foam. This foam cushions the contents, absorbing any jolts or impacts that may occur during transportation. Additionally, a waterproofing layer is applied to the crate's exterior. This shields against moisture from rain, humidity in shipping containers, or condensation, ensuring that your goods arrive in pristine condition, no matter how long or arduous the journey.

About Us

Established in 2003, Shaanxi Yongtuo has emerged as a global powerhouse in the field of automated steel cutting systems, catering to over 50 countries. Our sprawling 20,000㎡ factory is a technological marvel. Inside, we deploy advanced AI - driven QC processes. These intelligent systems continuously monitor and analyze every stage of production. From the initial raw material inspection to the final assembly of machinery, they catch even the tiniest flaws, ensuring that only zero - defect products leave our facility. This unwavering commitment to quality has made us a trusted name worldwide.

Customer Visits & Exhibitions

Our factory tours offer a first-hand look at our precision manufacturing processes, state-of-the-art CNC equipment and rigorous quality control systems, and offer numerous opportunities to build long-term partnerships with our commitment to innovation, transparency and your success.

FAQs

Q: What's the minimum order quantity?

A: MOQ is 1 unit; bulk orders get 5–10% discounts.

Q: Can it cut curved rebars?

A: Yes! Our adaptive feeding system handles bends up to 30°.

Q: How long is delivery?

A: 30–60 days, depending on customization.

Q: Do you provide spare parts?

A: Yes—global express shipping for blades, sensors, and PLCs.

Q: Is training included?

A: Free 3-day onsite training for operators and technicians.

Contact Us

📧 Email: sxyongtuo@gmail.com

📍 Factory Address: Xianyang City, Shaanxi Province, China

Upgrade Your Productivity Today with Yongtuo's Steel Bar Cutting Production Line! Where Innovation Meets Reliability.

YOU MAY LIKE

_1744680888628.png)