2.Servo-controlled length measurement ensures high precision and good consistency in material cutting.

3.200-ton shearing cylinder for high production efficiency.

4.Equipped with a scrap collection box for centralized collection of leftover material.

5.Double-sided, three-position finished product collection bin to accommodate centralized collection of various specifications.

6.The collection bin is equipped with a steel chain for collection, reducing noise during collection.

7.Optional automatic raw material loading device to reduce the labor intensity of loading work."

High-Precision Rod Cutting Production Line for Industrial Efficiency

Shaanxi Yongtuo Machinery Technology Co., Ltd, a trusted Rod Cutting Production Line manufacturer since 2003, delivers advanced CNC cutting solutions for metal processing, automotive, and aerospace industries. With 37 patents, a mature R&D team, and 24/7 after-sales support, our machines ensure precision, energy efficiency, and reliability.

Why Choose Our product?

✅ Servo-Controlled Precision: Achieve ±0.5mm cutting accuracy for consistent results.

✅ 200-Ton Shearing Power: Boost productivity with 30-50 cuts per minute.

✅ Scrap Collection System: Reduce material waste by 15% with centralized scrap boxes.

✅ Noise-Reduced Collection: Steel-chain bins lower operational noise to <75dB.

✅ Customizable Automation: Add robotic loading to cut labor costs by 40%.

Key Features & Advantages

🔹 High-Quality Feeding System: Smooth material transfer for uninterrupted operation.

🔹 Double-Sided Collection Bins: Sort 3 sizes of finished rods without downtime.

🔹 Energy-Saving Design: 20% lower power consumption vs. competitors.

🔹 IoT-Ready Interface: Monitor performance via touchscreen with data export options.

🔹 Durable Construction: Hardened steel blades last 2x longer than industry standards.

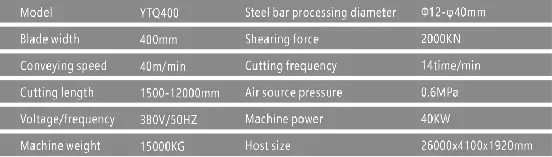

Technical Parameters

Applications

Our Rod Cutting Production Line serves:

- Construction: Bulk steel rebar cutting for bridges and buildings.

- Automotive: Precision-cut alloy rods for engine components.

- Aerospace: Titanium/carbon fiber cutting with zero burrs.

- Energy Sector: Cable tray and transmission tower fabrication.

Tailored Solutions

- Non-Standard Materials: Customize blade types for copper, PVC, or composites.

- Length Adjustments: Modify cutting ranges from 0.5m to 15m.

- Automation Upgrades: Integrate AGV robots for raw material handling.

Certifications

✔️ ISO 9001:2015 Certified

✔️ CE Compliance

✔️ RoHS Environmental Standard

Reliable After-Sales Service

- 12-month warranty with ≤12-hour fault response.

- Free remote diagnostics via 13892319900@sxyongtuo.com.

- On-site technician support in 48 hours (China).

Secure Packaging

Our Rod Cutting Production Line are dispatched with the utmost care to ensure they reach you in perfect condition. Each is securely packed within waterproof wooden crates, which are not only robust but also treated with anti - rust coatings. This dual - layer protection shields the machinery from moisture - induced corrosion, a common risk during long - distance shipping. Additionally, for enhanced security and real - time tracking, every crate is equipped with GPS technology. This allows you to monitor the exact location of your valuable equipment throughout its journey, providing peace of mind from dispatch to delivery.

About Shaanxi Yongtuo

With over 20 years of unwavering dedication to CNC machinery, we have successfully served a staggering 500+ clients dispersed across 30 countries worldwide. Our state - of - the - art 20,000㎡ factory, strategically located in Xi'an, is a hub of innovation. Here, we blend cutting - edge AI testing procedures to meticulously evaluate each product's performance. Coupled with lean manufacturing principles, we eliminate waste and streamline production. This harmonious combination ensures an unmatched quality standard, making us the go - to choice for clients seeking top - tier CNC solutions globally.

Exhibition

At the exhibition, our technical and sales teams will provide you with professional consultation, prototype operation demonstrations and customized service suggestions. Welcome to visit our booth to communicate with us face to face and explore cooperation opportunities together.

Customer Visits

We warmly welcome customers from all over the world to visit our Xi'an factory headquarters. The factory covers an area of 12,000 square meters and integrates R&D, production, assembly and testing. Through field visits, customers can gain an in-depth understanding of our production processes, quality control systems and technical R&D capabilities.

FAQ

Q: Can this machine cut irregular-shaped materials?

A: Yes! Custom blade configurations are available for hexagonal/oval rods.

Q: What's the ROI period?

A: Most clients recover costs in 8-12 months via reduced waste and labor.

Q: Do you provide installation training?

A: Free 3-day onsite training included with every purchase.

Q: How long is the lead time?

A: 15-30 days for standard models; 45 days for customized units.

Q: What payment terms do you accept?

A: T/T, LC, or Alibaba Trade Assurance.

Optimize Your Production Today!

Contact our experts for a free cutting efficiency analysis: 📧 sxyongtuo@gmail.com

Invest in Shaanxi Yongtuo's Rod Cutting Production Line – where innovation meets industrial reliability.

YOU MAY LIKE

_1744680888628.png)