2.Servo-controlled length measurement ensures high precision and good consistency in material cutting.

3.200-ton shearing cylinder for high production efficiency.

4.Equipped with a scrap collection box for centralized collection of leftover material.

5.Double-sided, three-position finished product collection bin to accommodate centralized collection of various specifications.

6.The collection bin is equipped with a steel chain for collection, reducing noise during collection.

7.Optional automatic raw material loading device to reduce the labor intensity of loading work."

Vertical CNC Bending Machine Production Line | Precision & Efficiency by Shaanxi Yongtuo

Shaanxi Yongtuo Machinery Technology Co., Ltd, a trusted Vertical CNC Bending Machine production line manufacturer since 2003, delivers advanced metal-forming solutions for industries requiring precision, reliability, and energy efficiency. With 37 patents, a mature R&D team, and ISO-certified services, we empower manufacturers to streamline operations and reduce costs.

Why Choose Our product?

- ✅ 37 Patented Technologies – Cutting-edge innovation for unmatched accuracy (±0.1mm).

- ✅ 24/7 Rapid Response – On-site maintenance within 12 hours (domestic).

- ✅ 20,000+㎡ Smart Factory – Rigorous quality control from raw materials to final assembly.

- ✅ 1:1 ROI in 18 Months – Energy-saving design reduces power consumption by 30%.

- ✅ Global Compliance – CE, ISO 9001, and China GB standards.

Features and Advantages

- Servo-Driven Length Measurement: Achieve ±0.05mm cutting precision for consistently accurate results—ideal for electronics and precision parts manufacturing.

- 200-Ton Shearing Force: Powerful and precise cutting with minimal deviation, reducing scrap and boosting efficiency in high-strength material processing.

- Noise-Reduced Collection System: Steel-chain bins lower operational noise by up to 50%, improving workplace conditions and ensuring compliance with noise regulations.

- IoT-Ready SmartControl®: Monitor, diagnose, and adjust machine performance remotely via Yongtuo SmartControl®, enabling real-time insights and efficient factory management.

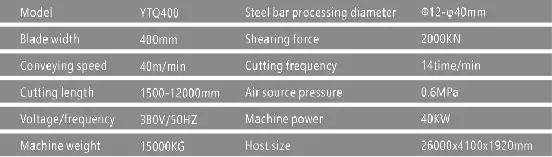

Technical Specifications

Industries We Serve

From automotive chassis to wind turbine rings, our Vertical CNC Bending Machine production line stand out with unrivaled expertise.

In the automotive realm, we specialize in crafting exhaust pipes for optimal exhaust flow and suspension components that ensure a smooth ride.

In aerospace, our precision - bent engine mounts and wing ribs uphold the highest safety and performance standards.

For construction, our CNC - bent steel trusses provide robust structural support, while facade panels created by our solutions add both strength and aesthetic appeal to buildings.

Whether it's high - speed cars, high - flying aircraft, or towering structures, our solutions deliver excellence.

After-Sales Service

We provide comprehensive after-sales guarantee services to every customer, including 24/7 remote technical support, 1-year core component warranty, free operation training and lifelong technical guidance. Through video remote diagnosis, problems can be quickly solved to ensure stable operation of equipment and worry-free production.

Exhibitions

We actively participate in global industry exhibitions to showcase the latest research and development results and core products. Whether it is BAUMA in Germany or SteelFab in the UAE, you can experience our high-precision equipment on site, watch real machine demonstrations, and have in-depth face-to-face exchanges with our engineers to discuss cooperation opportunities.

Customer Visits

We sincerely welcome customers from all over the world to visit our Xi'an factory. Over the years, purchasing representatives, technical experts and partners from more than 30 countries have visited the site to learn about our manufacturing processes, quality control and R&D capabilities. Every visit is the starting point of cooperation and trust.

FAQ

Q: What precision level can I expect?

A: Our servo - controlled systems guarantee ±0.1mm repeatability, making them ideal for aerospace and medical device manufacturing where minute inaccuracies are not tolerable.

Q: Do you offer financing options?

A: Yes! We provide flexible terms including a 30% down payment followed by 12 - month installments to ease your investment burden.

Q: What is the lead time for production and delivery?

A: Typically, after order confirmation, production takes around 4 - 6 weeks. Delivery times vary based on your location, with domestic shipments usually taking 1 - 2 weeks and international deliveries ranging from 2 - 4 weeks, depending on customs clearance.

Q: Can your machines be customized?

A: Absolutely. We understand that different clients have unique requirements. Our machines can be customized in terms of bending capacity, automation level, and additional features to suit your specific production needs.

Q: What kind of after - sales support do you offer?

A: We offer comprehensive after - sales support. This includes a 1 - year warranty on all our machines. Our technical team is available 24/7 to provide remote or on - site assistance for any maintenance or repair issues. We also offer training programs to ensure your operators can use the machines to their full potential.

Contact Us

Optimize your metal fabrication with Yongtuo's Vertical CNC Bending Machine production line – where precision meets productivity. Contact us at sxyongtuo@gmail.com for a free layout design!

YOU MAY LIKE

_1744680888628.png)