2.Servo-controlled length measurement ensures high precision and good consistency in material cutting.

3.200-ton shearing cylinder for high production efficiency.

4.Equipped with a scrap collection box for centralized collection of leftover material.

5.Double-sided, three-position finished product collection bin to accommodate centralized collection of various specifications.

6.The collection bin is equipped with a steel chain for collection, reducing noise during collection.

7.Optional automatic raw material loading device to reduce the labor intensity of loading work."

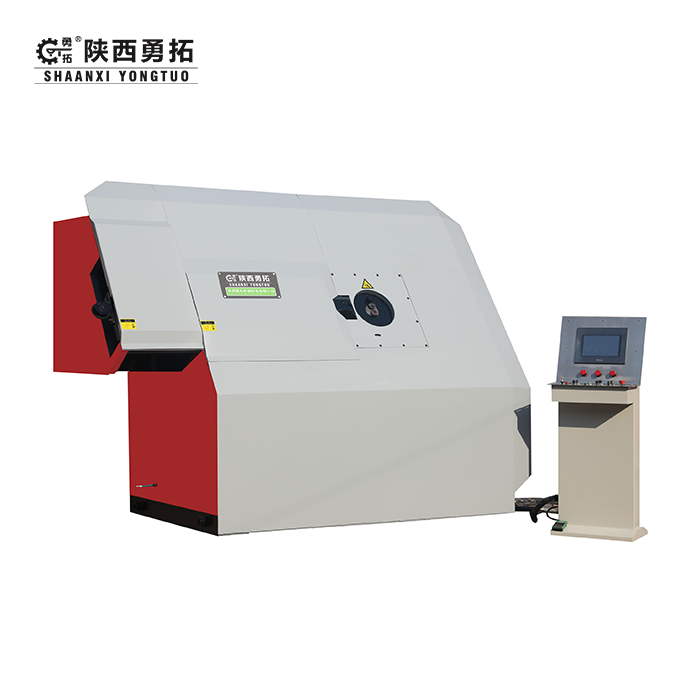

High-Efficiency Bar Cutting Manufacturing Line for Precision Metal Processing

Shaanxi Yongtuo Machinery Technology Co., Ltd is a trusted Bar Cutting Manufacturing Line manufacturer and supplier with 20+ years of expertise. Our advanced servo-controlled systems, 200-ton shearing power, and modular designs ensure energy-efficient, precise, and low-maintenance operations for industries like construction, automotive, and metal fabrication.

Why Choose Our product?

✅ R&D Excellence: 37 patents and ISO 9001 certification guarantee cutting-edge technology.

✅ Proven Export Experience: Relied on by clients in 30+ countries since 2003.

✅ 24/7 Support: ≤12-hour fault response with remote diagnostics and on-site maintenance.

✅ Energy Savings: Up to 30% lower power consumption vs. traditional models.

✅ Customization: Adaptable to diameters of 6–50mm and integration with IoT systems.

Key Features & Advantages

✔️ High-Precision Servo Control: ±0.5mm length tolerance for consistent output.

✔️ Dual-Sided Collection Bins: Reduce downtime with 3-position sorting (lengths: 1–12m).

✔️ Scrap Recycling System: Centralized scrap collection minimizes material waste.

✔️ Noise Reduction: Steel-chain conveyors operate at <75dB.

✔️ Optional Automation: Add robotic loading arms for fully unmanned production.

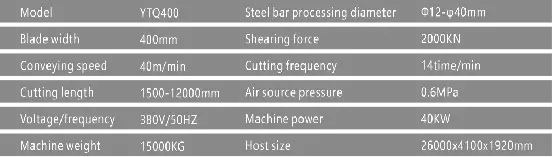

Technical Parameters

Applications

- Construction: Rebar cutting for beams, columns, and slabs.

- Automotive: Precision metal rods for engine components.

- Energy: Steel brackets for solar panels and wind turbines.

- Aerospace: High-tolerance alloy cutting.

Customization Options

- Material Compatibility: Adjust for stainless steel, aluminum, or copper.

- Software Integration: Connect to ERP/MES for real-time data tracking.

- Safety Upgrades: Laser guards or emergency stop systems.

Certifications

Our company's products and services are backed by a robust set of quality assurances. We hold the ISO 9001:2015 certification, demonstrating our commitment to maintaining high - quality management systems in all aspects of production. The CE Mark attests to our compliance with European safety, health, and environmental protection standards. Having been SGS Audited, we've undergone rigorous third - party inspections, ensuring our operations meet international benchmarks. Moreover, we offer a comprehensive 12 - month warranty, giving our customers peace of mind, knowing they're investing in reliable and durable products.

After-Sales Service

- Free Training: On-site operator and technician training.

- Spare Parts Kits: Pre-packaged essentials for quick replacements.

- Lifetime Support: Software updates and retrofitting services.

Packaging & Shipping

Our commitment to ensuring the safe arrival of your products starts with the packaging. We use waterproof wooden crates, providing a sturdy outer shell. These crates are further fortified with anti - rust coatings, safeguarding your items from moisture and potential corrosion during transit.

About Shaanxi Yongtuo

Founded in 2003, we've delivered 5,000+ Bar Cutting Manufacturing Lines worldwide. Our 200-acre factory in Xi'an combines AI-driven QC systems with a 15-person R&D team to ensure industry-leading innovation.

Customer Visits & Exhibitions

By showcasing the latest products and technological achievements, we are able to attract potential customers, grasp industry dynamics, keep up with market trends, and inject continuous impetus into the sustainable development of the company.

FAQs

Q: Can this line handle irregularly shaped bars?

A: Yes! Our servo system adapts to oval or ribbed surfaces.

Q: What's the lead time for customization?

A: 45–60 days, including factory testing.

Q: Do you provide installation overseas?

A: Yes – our engineers can assist onsite or via live video.

Q: How often is maintenance needed?

A: Every 500 operating hours for lubrication and calibration.

Q: Is financing available?

A: We offer lease-to-own plans with 0% APR for 12 months.

Contact Us Today!

📧 Email: sxyongtuo@gmail.com

Optimize your metal processing with Yongtuo's Bar Cutting Manufacturing Line – where precision meets productivity!

YOU MAY LIKE

_1744680888628.png)

_1760057043461.webp)