2.Servo-controlled wire feeding and bending, with high precision in feeding length and bending angle.

3.Servo controlled cutting, high cutting frequency, can cut continuously at high frequency.

4.Wire feeding and bending adopt planetary reducer as torque transmission, which has high torque transmission efficiency, high precision and long service life."

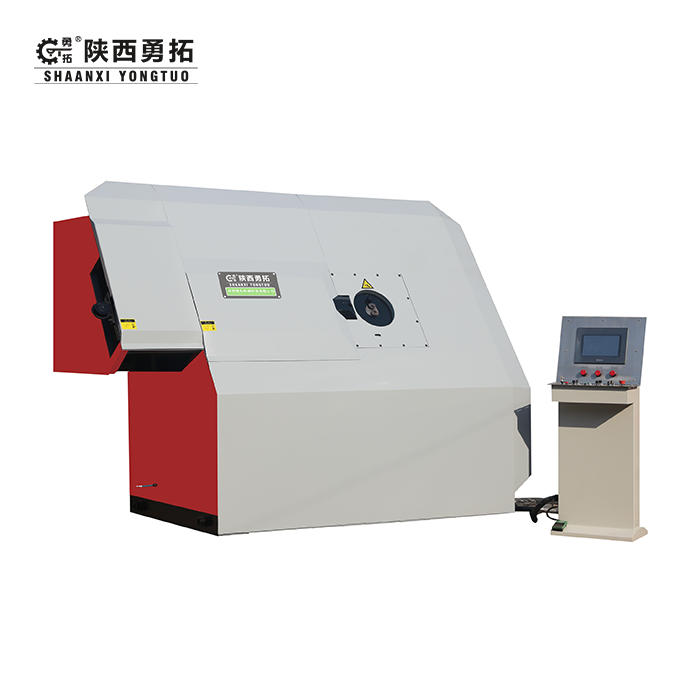

Shaanxi Yongtuo: Your Trusted Partner in Automated Steel Bar Processing

Shaanxi Yongtuo Machinery Technology Co., Ltd, established in 2003, is a leading Fully Automatic Bar Bending Production Line manufacturer with 37 patents, a certified R&D team, and a global clientele. Our machines deliver 30% higher efficiency, ±0.5mm precision, and 24/7 after-sales support, making us the preferred choice for construction giants and metal fabricators worldwide.

Why Choose Us?

✅ 20+ Years of Expertise: Mature R&D team with ISO 9001 certification.

✅ Energy-Saving Design: Reduce material waste by 15% with compact servo systems.

✅ Global Export Experience: Machines deployed in 50+ countries.

✅ 1-Year Warranty: On-site maintenance within 12 hours (domestic).

✅ End-to-End Support: Pre-sales consultation, installation training, and lifetime technical guidance.

Key Features & Advantages

- Servo-Controlled Precision: Achieve ±0.5mm accuracy in bending angles and cutting lengths.

- Planetary Reducer Technology: High torque transmission for 50,000+ hours of uninterrupted operation.

- High-Frequency Cutting: Process 120 bends/minute for large-scale projects.

- Modular Design: Easily integrate with existing ERP/MES systems for smart facto

- ries.

- Energy Efficiency: 20% lower power consumption vs. traditional models.

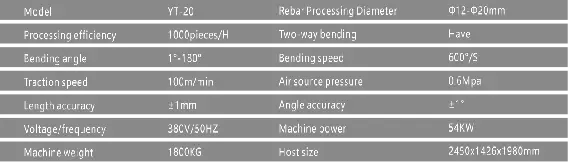

Technical Parameters

|

Application Areas

- High-Rise Buildings: Rapidly produce standardized rebar cages.

- Precast Concrete: Custom bends for beams, columns, and slabs.

- Renewable Energy: Wind turbine bases, solar farm reinforcements.

- Infrastructure: Bridges, tunnels, and highway guardrails.

Customization Options

Tailor your production line with:

🔧 Non-standard bending angles (e.g., 135° seismic hooks).

🔧 Dual-material processing (steel + fiberglass rebar).

🔧 IoT-enabled remote monitoring via Yongtuo's proprietary app.

Certifications

- ISO 9001:2015 Quality Management

- CE Certification (EU Compliance)

- China National Building Standard Design Accreditation

After-Sales Service

- 24/7 Remote Diagnostics: Instant troubleshooting via video call.

- Spare Parts Guarantee: Global warehouses ensure ≤3-day delivery.

- Lifetime Upgrades: Free software updates for smarter operations.

Packaging & Shipping

Our waterproof wooden crates are engineered to offer comprehensive protection for your valuable items. The wooden exterior is treated with a specialized waterproof sealant that forms a robust barrier against moisture, preventing water from seeping in and causing damage. Additionally, an anti - rust coating is meticulously applied to all metal components within the crate. This coating not only shields the metal from oxidation and rust, but also enhances its durability.

For our international clients, we offer flexible and widely - recognized trade terms, namely FOB (Free on Board) and CIF (Cost, Insurance, and Freight). With FOB, clients have the option to arrange their own shipping and take responsibility once the goods are loaded onto the vessel at the specified port. On the other hand, CIF terms provide a more comprehensive service. We handle the cost of shipping, insurance, and all associated freight charges until the goods reach the agreed - upon destination port. This allows our clients to choose the option that best suits their logistics and budget requirements, ensuring a seamless and hassle - free international trade experience.

About Shaanxi Yongtuo

With a sprawling 50,000㎡ factory equipped with state - of - the - art machinery and staffed by over 200 highly skilled technicians, our production capabilities are truly remarkable. Leveraging our expertise, we've successfully supplied Fully Automatic Bar Bending Production Lines to high - profile mega - projects. In Egypt's New Capital, our equipment has played a crucial role in the rapid construction of modern infrastructure. Similarly, for India's Mumbai Metro, our lines have efficiently bent steel bars, ensuring the project's seamless progress. These achievements underscore our position as a reliable partner for large - scale construction undertakings worldwide.

FAQs

Q: What's the ROI period for this machine?

A: Most clients recover costs in 18–24 months via labor reduction and waste control.

Q: Do you provide operator training?

A: Yes – 3-day onsite training included with every purchase.

Q: Can it process ribbed steel bars?

A: Absolutely! Our servo feeders handle ribbed surfaces without slippage.

Q: How often is maintenance needed?

A: Minimal upkeep – lubricate gears every 500 operating hours.

Ready to Upgrade Your Rebar Workshop?

📧 Email: sxyongtuo@gmail.com

Trust Shaanxi Yongtuo's Fully Automatic Bar Bending Production Line – where innovation meets reliability. Let's build smarter, together!

YOU MAY LIKE

_1744680888628.png)