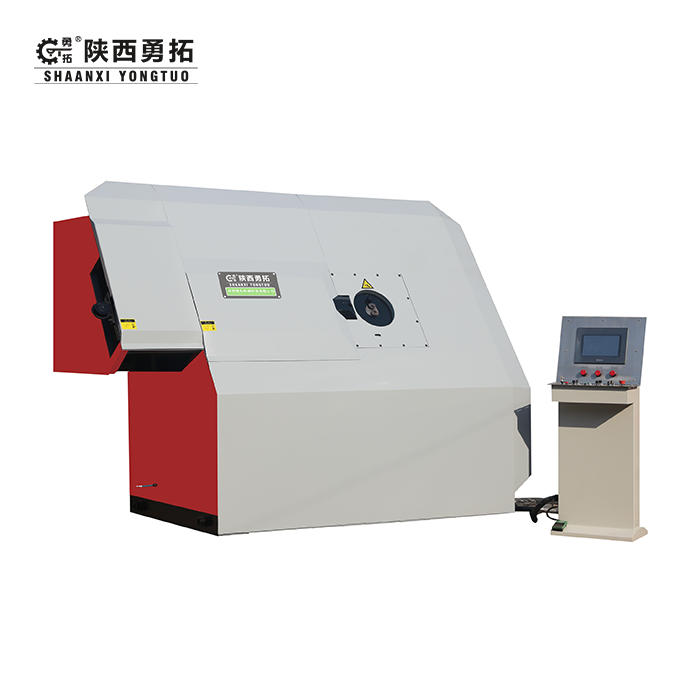

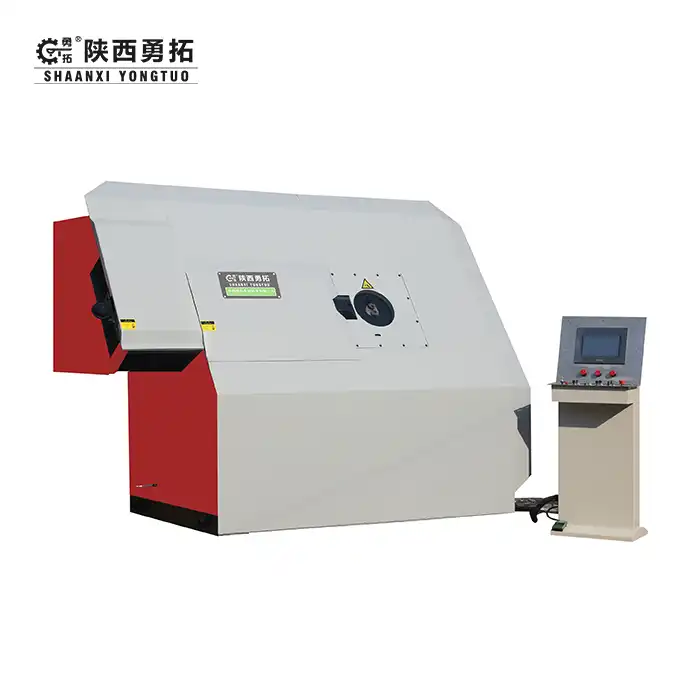

2.Bending rotation speed is adjustable, providing high processing flexibility.

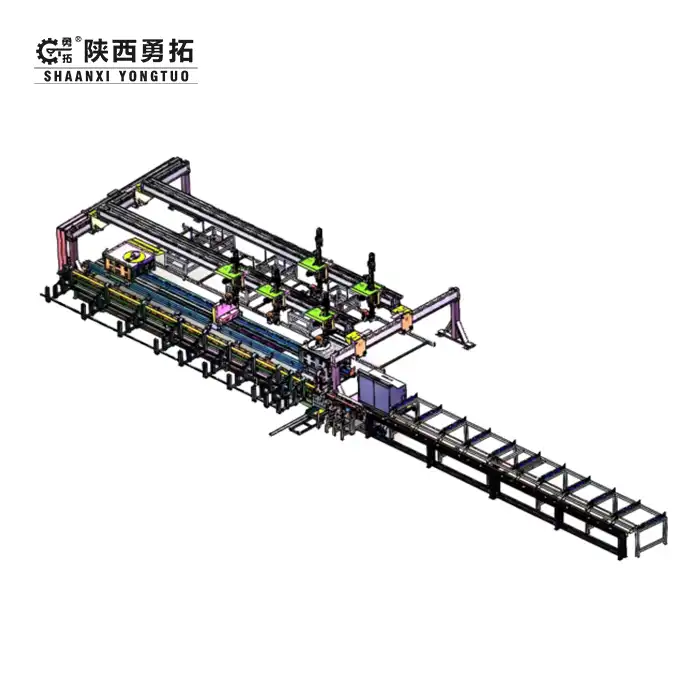

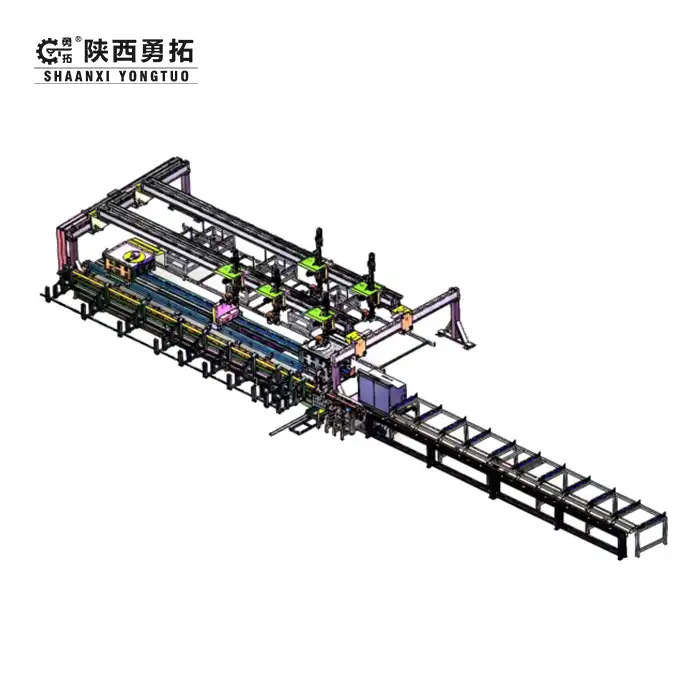

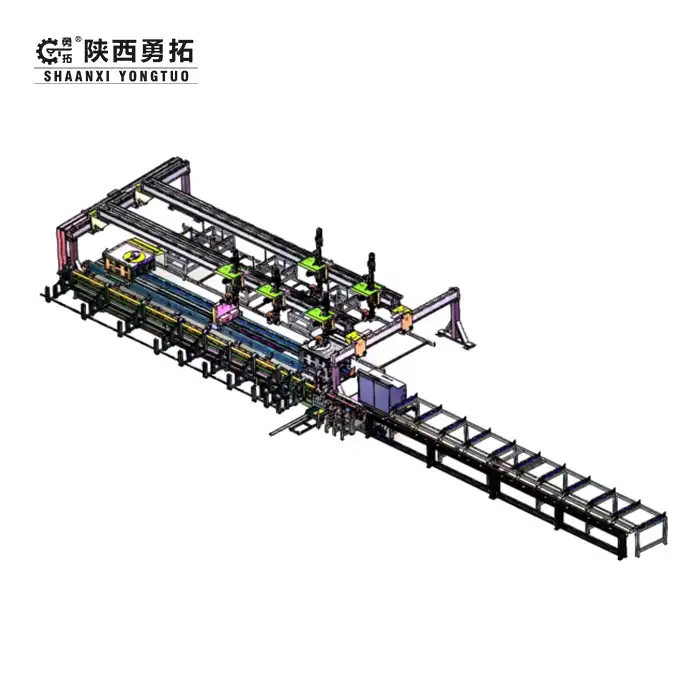

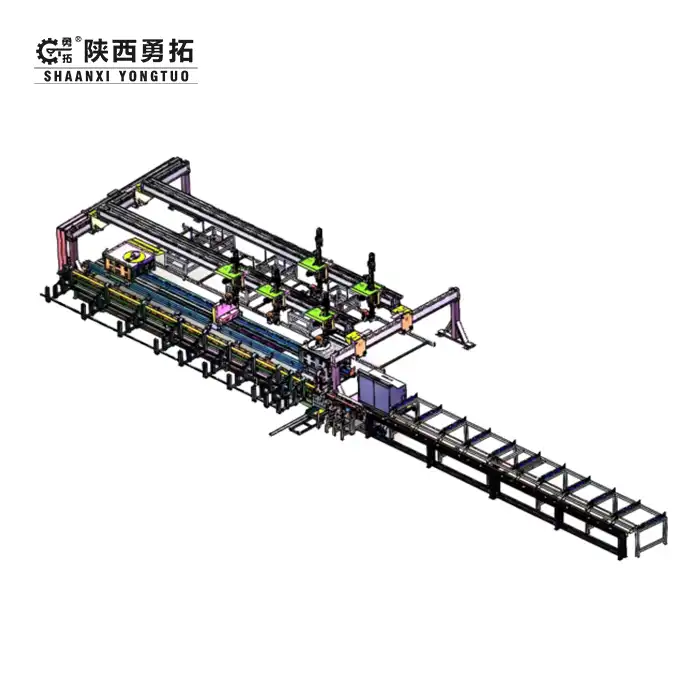

3.Equipped with three sets of three-axis robotic arms for bending material feeding.

4.Equipped with two sets of three-axis robotic arms for finished product collection.

5.Separate execution of bending feeding and finished product collection increases production efficiency.

6.Multi-station finished product storage bins allow simultaneous collection of products of various specifications.

7.Planetary reducer used for torque transmission during bending, resulting in low noise, high precision, and long service life.

8.Multi-piece flexible clamping system effectively secures multiple rebars, ensuring consistent processing dimensions.

9.Optional automatic raw material feeding system reduces feeding workload."

Shaanxi Yongtuo Machinery Technology Co., Ltd – Your Trusted Partner

Shaanxi Yongtuo Machinery Technology Co., Ltd, established in 2003, has been a pioneer in the industry for over two decades. Specializing in manufacturing advanced Bar Shearing and Bending Workstations, we serve global clients with unrivaled dedication. Our 37 patents are a clear indication of our innovative prowess, while our professional R&D team constantly explores new frontiers in technology. The ISO/CE certifications we hold attest to the high quality and safety standards of our products. Leveraging our 20+ years of expertise, we consistently deliver reliable, energy - efficient solutions that not only meet but exceed the expectations of our customers worldwide.

Why Choose Our Bar Shearing and Bending Workstation?

✅ Proven Performance: Over 500 units deployed globally, with 98% client satisfaction.

✅ Full Automation: Integrated feeding, cutting, bending, and collection – reduce labor costs by 50%.

✅ Energy Efficiency: 30% lower power consumption vs. traditional machines.

✅ 24/7 Support: ≤12-hour fault response, remote diagnostics, and on-site maintenance.

✅ Custom Solutions: Adaptable to unique specifications (angles, lengths, materials).

Features & Advantages

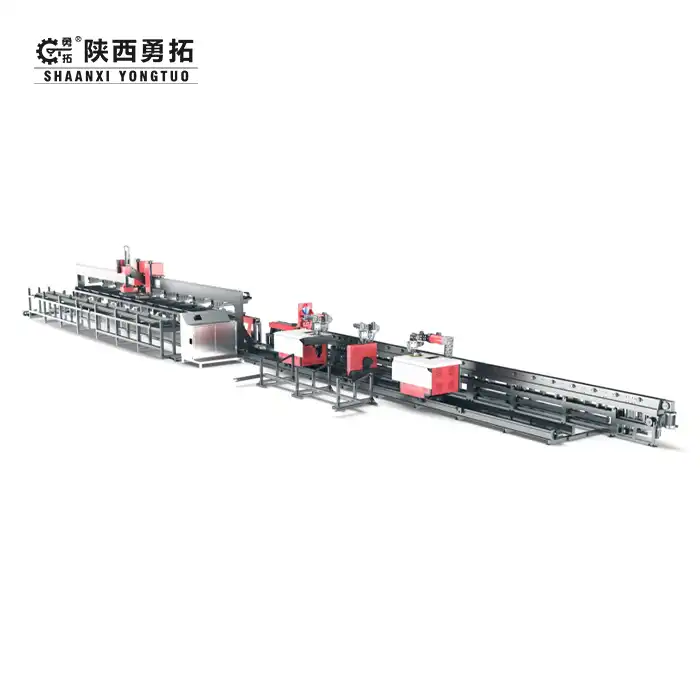

- Fully Automated Process: Seamlessly integrates feeding, fixed-length cutting, bending, and product collection.

- Adjustable Bending Speed: 0-30 RPM range for diverse rebar specifications.

- Robotic Precision: 3 sets of three-axis robotic arms for bending; 2 sets for product collection.

- Planetary Reducer: Low noise (<75 dB), high torque, and 50,000-hour lifespan.

- Multi-Piece Clamping: Secures 6-12 rebars simultaneously for uniform dimensions.

- Optional Feeding System: Automate raw material loading to reduce manual work.

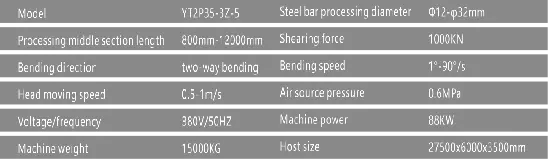

Technical Parameters

Applications

- Construction: High-rise buildings, bridges, tunnels.

- Manufacturing: Precast concrete, steel structures.

- Infrastructure: Railways, highways, hydropower plants.

- Rental Services: Short-term project flexibility.

Customization Options

Tailor your workstation with:

- IoT Integration: Remote monitoring and data reporting.

- Material Handling: Upgrade to automated feeding/conveyor systems.

- Safety Features: Laser guards, emergency stop systems.

Certifications

Our Bar Shearing And Bending Workstation hold ISO 9001, CE, and SGS certifications, which are globally recognized symbols of quality, safety, and reliability. The ISO 9001 certification validates our commitment to maintaining a high - quality management system in all aspects of production. The CE mark ensures that our products meet the strict safety, health, and environmental protection requirements set by the European Union. With SGS certification, our products have undergone rigorous third - party testing. Moreover, we are fully compliant with GB/T (China), EN (EU), and OSHA standards. This means that whether you are in China, the EU, or operating under OSHA regulations in the United States, you can trust our products to meet the local industry benchmarks.

After-Sales Service

- 24-month warranty.

- Free online training + multilingual manuals.

- Global spare parts network (72-hour delivery).

Packaging & Shipping

Your products will be securely packaged in waterproof wooden crates filled with shock - absorbent foam. This packaging not only safeguards against water damage during transit but also cushions the items from any potential jolts or impacts. We offer flexible shipping options, including FOB (Free on Board) and CIF (Cost, Insurance, and Freight). With a lead time of 15 - 25 days, you can expect a timely delivery. Our logistics team will handle all the necessary arrangements, ensuring your goods reach their destination in perfect condition, whether it's across the ocean or to a nearby port.

About Us

Situated in Xi'an, our sprawling 20,000㎡ factory is a hub of efficient production. Equipped with state - of - the - art machinery and a skilled workforce, we are well - positioned to meet the diverse demands of our clients. We have successfully served clients in 30+ countries around the globe. Prominent among them are Sinohydro and China Railway Group, two industry giants. Our ability to cater to such large - scale enterprises is a testament to our high - quality products, whether it's advanced construction equipment or precision - engineered components, which have won us a solid reputation in the international market.

FAQs

Q: Can it process stainless steel rebars?

A: Yes! Customizable tooling for stainless steel, alloy steel, and more.

Q: What's the ROI period?

A: Typically 8-14 months via labor savings.

Q: Do you provide installation?

A: Yes – global technician dispatch available.

Contact Us for Your Bar Shearing and Bending Workstation Needs!

YOU MAY LIKE

_1744680888628.png)