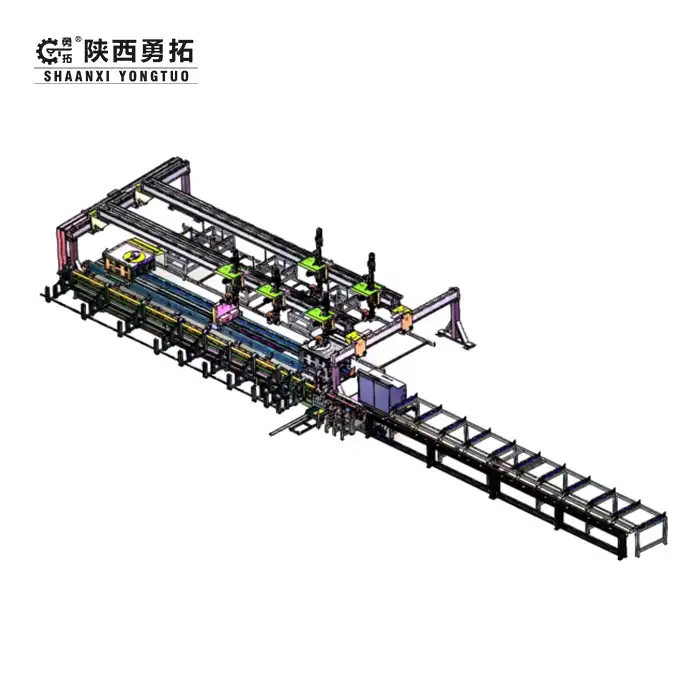

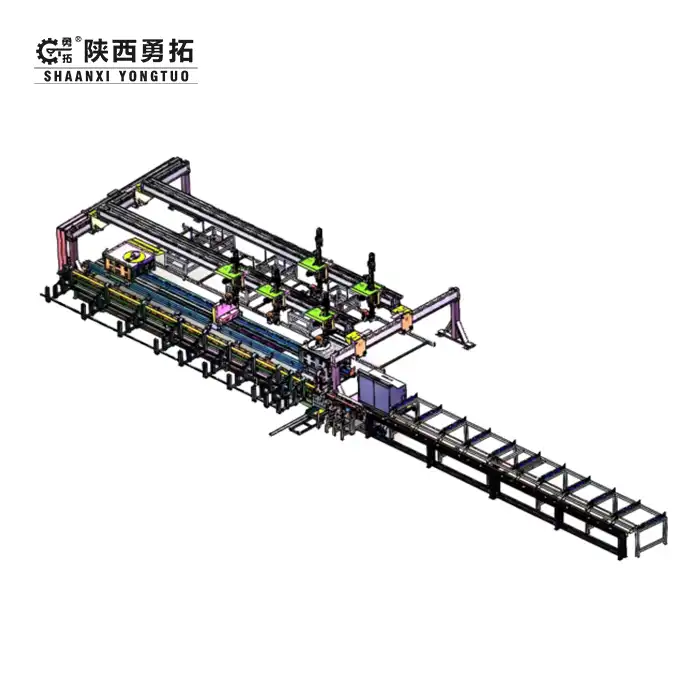

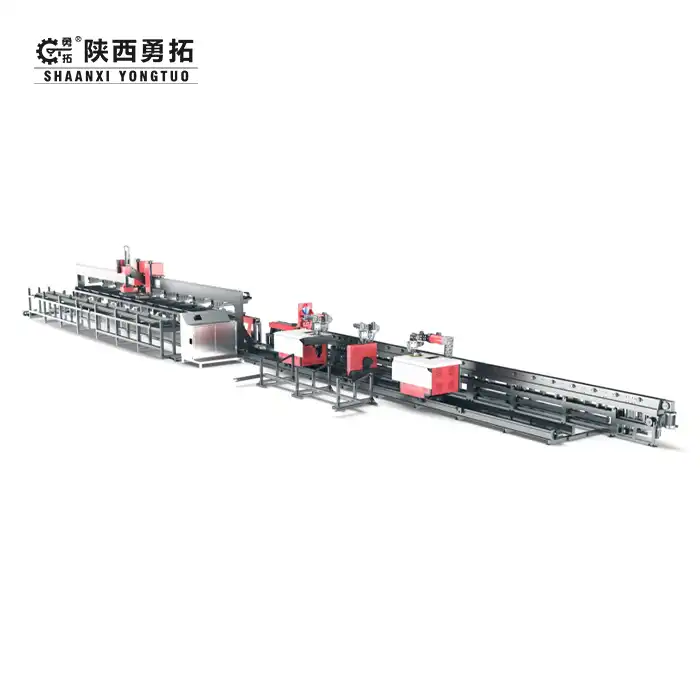

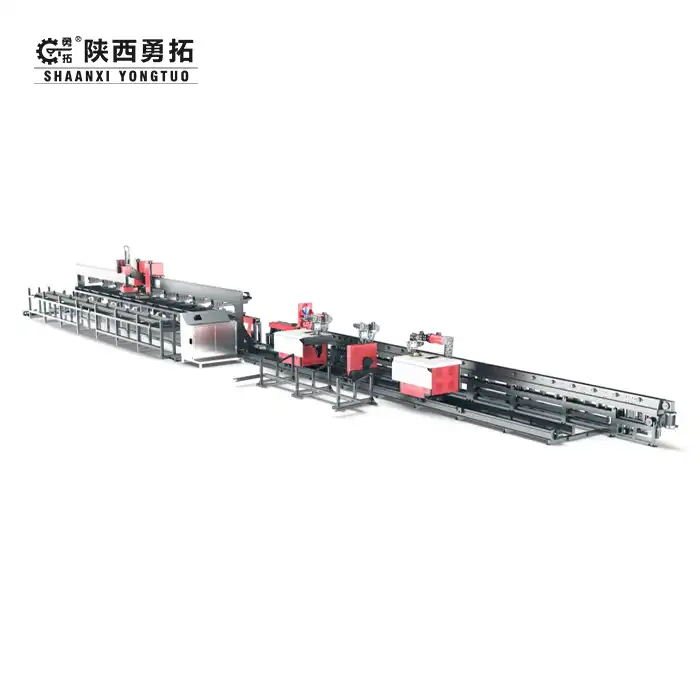

2.Equipped with three sets of three-axis robots for bending material feeding and finished product collection.

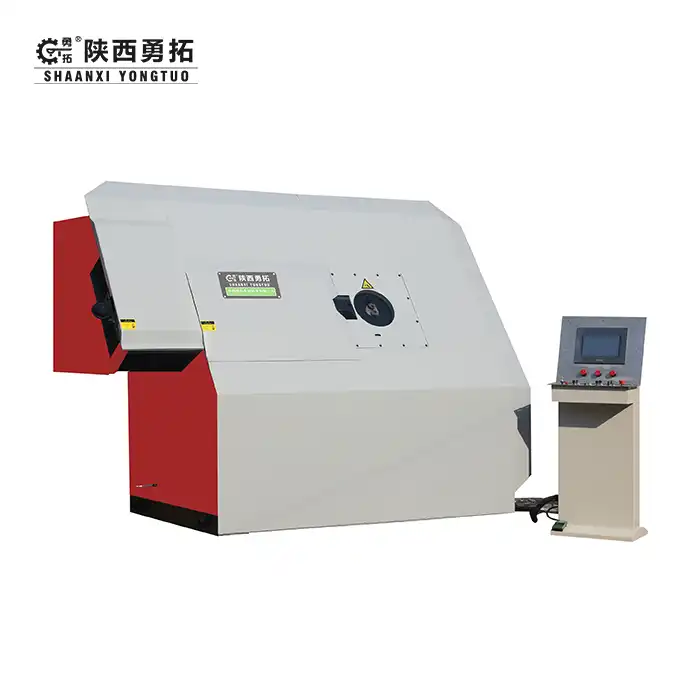

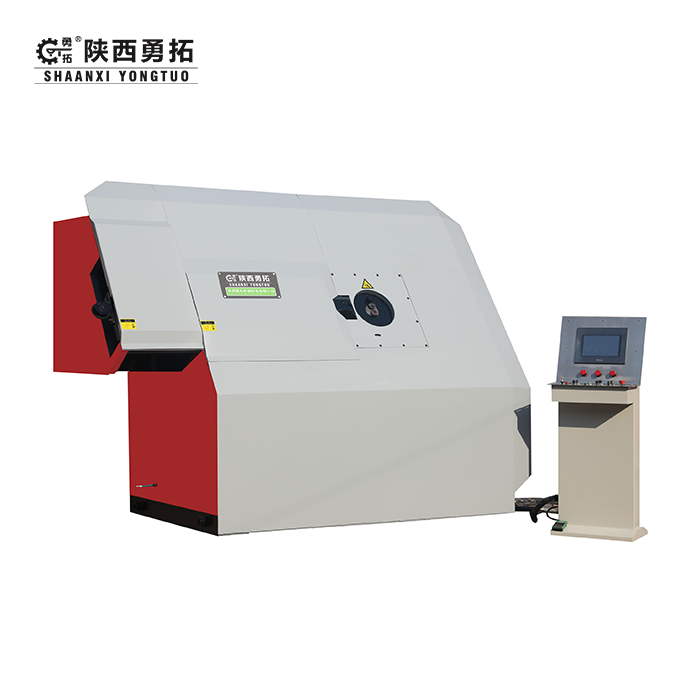

3.The bending rotation speed can be set arbitrarily, offering greater processing flexibility.

4.The planetary reducer is used for torque transmission during bending, ensuring low noise, highprecision,and long service life.

5.The middle clamping system uses a multi-piece flexible clamp, effectively securing multiple rebars and ensuring consistent dimensions for all processed rebars.

6.Optional automatic raw material feeding system is available, reducing the labor intensity of feeding operations."

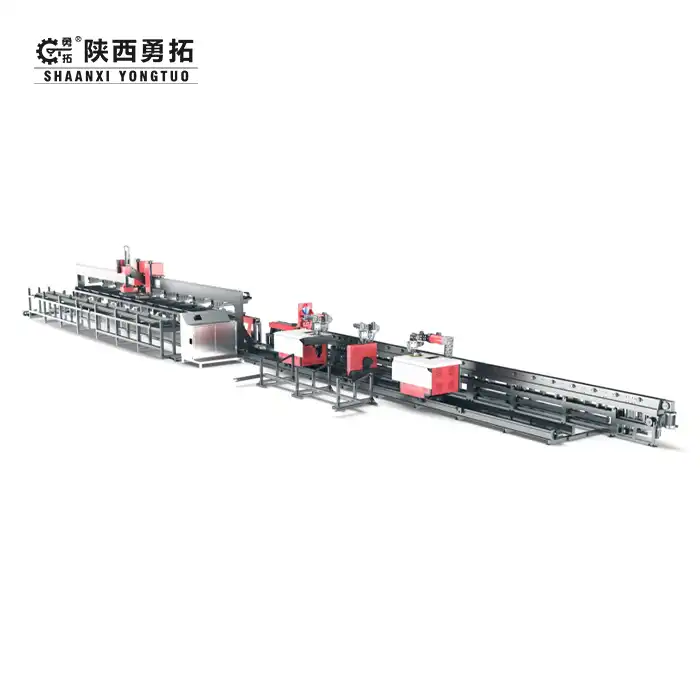

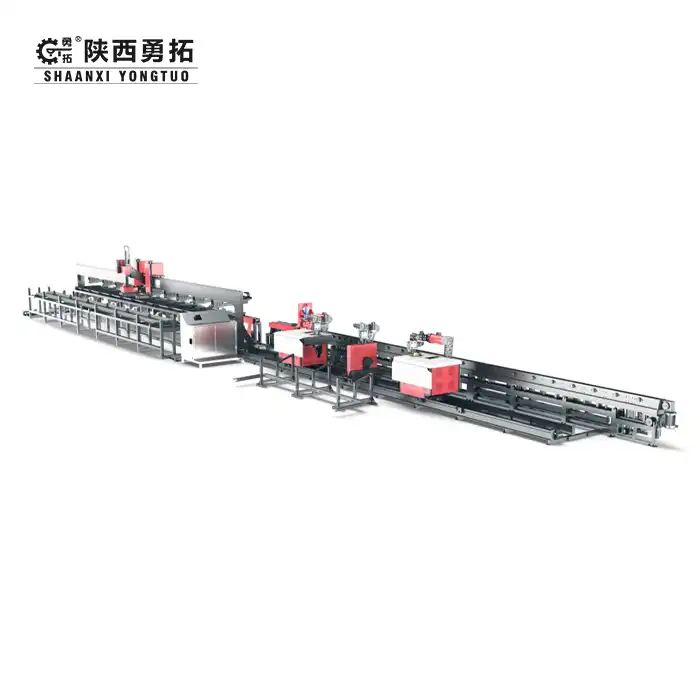

Elevate Your Rebar Processing with Shaanxi Yongtuo's Rebar Shearing and Bending Robot Production Line

For construction firms, prefab factories, and infrastructure projects, precision and speed are non-negotiable. Shaanxi Yongtuo Machinery Technology Co., Ltd, a leading Rebar Shearing and Bending Robot Production Line manufacturer since 2003, delivers fully automated solutions that cut labor costs by 50% and boost output by 200%. With 37 patents and a 12-hourFailureResponse, we empower global clients to achieve error-free preparation of reinforcement.

Why Choose Shaanxi Yongtuo?

- Advanced R&D: 20+ years in steel bar processing tech, ISO 9001-certified.

- End-to-End Automation: From feeding to bending to collection – zero manual intervention.

- Global Support: 24/7 multilingual service for EU, ASEAN, and Middle East markets.

- ROI-Driven Design: 1.5-year average payback period (proven inHSR projects).

- Smart Energy Use: 30% lowerenergy consumption vs. traditional machines.

Features & Advantages

- All-in-One Processing: Integrates cutting, bending, and collection via 3 robotic arms.

- High-Speed Bending: Adjustable rotation (0-60 RPM) for complex shapes (e.g., spiral stirrups).

- Precision Clamping: Multi-piece flexible fixture holds 6-40mm, rebar with ≤0.5mm error.

- Planetary Reducer: 50,000-hour lifespan, 60dBlow noise operation.

- Optional Feeding System: Auto-loads 12mraw material, saving 3 workers/shift.

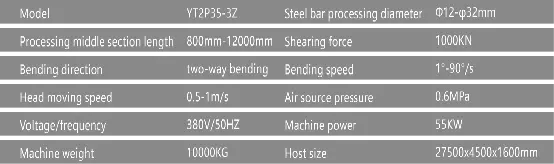

Technical Parameters

Application Areas

- High-Rise Buildings: Mass-produce floor slabs' reinforcement cages.

- Bridges/Tunnels: Bend 32mm rebar into arch shapes for suspension bridges.

- Precast Concrete: Daily output: 50-tonReinforcing bars for prefabricated beams.

- Metal Workshops: Customize hooks, U-bends for machinery parts.

Customization & Compliance

- Modular Design: Add IoT sensors for MES integration or CE/OSHA-compliant safety guards.

- Certifications: ISO 9001, CE, and GCC (for Middle East markets).

After-Sales Service

- 24/7 Remote Troubleshooting: Video call support in English/Arabic.

- On-Site Maintenance: Engineers dispatched within 12 hours (domestic).

- Spare Parts Guarantee: 10-year gearbox.

Exhibitions

Through face-to-face engagement, we build lasting relationships with clients and gain deeper insights into their evolving needs across industries.

FAQs

Q: Can this line process threaded steel?

A: Yes! Our flexible fixtures can securely hold ribbed bars. This design allows for smooth processing without slippage, ensuring high - quality results for your production needs.

Q: How to reduce material waste?

A: Our AI - powered cutting software optimizes cuts, saving up to 5% of steel materials. By analyzing various cutting patterns, it maximizes the use of raw materials, thus cutting down on unnecessary waste and costs.

Q: Is training included?

A: Absolutely. We offer free 3 - day training sessions for your operators. Additionally, a comprehensive 200 - page manual is provided, which serves as a useful reference for both training and daily operations.

Q: What are the payment terms?

A: The payment terms are 30% deposit to initiate the order, and the remaining 70% is due before shipment. This arrangement ensures a smooth and fair transaction process for both parties.

Q: What is the lead time?

A: For standard models, the lead time is 45 days. During this period, we meticulously assemble, test, and quality - check the product to ensure it meets our high - standard requirements before delivery.

Contact Us Today!

Email: sxyongtuo@gmail.com

Shaanxi Yongtuo – Your Partner in Smart Rebar Shearing and Bending Robot Production Line Solutions Since 2003.

YOU MAY LIKE

_1744680888628.png)