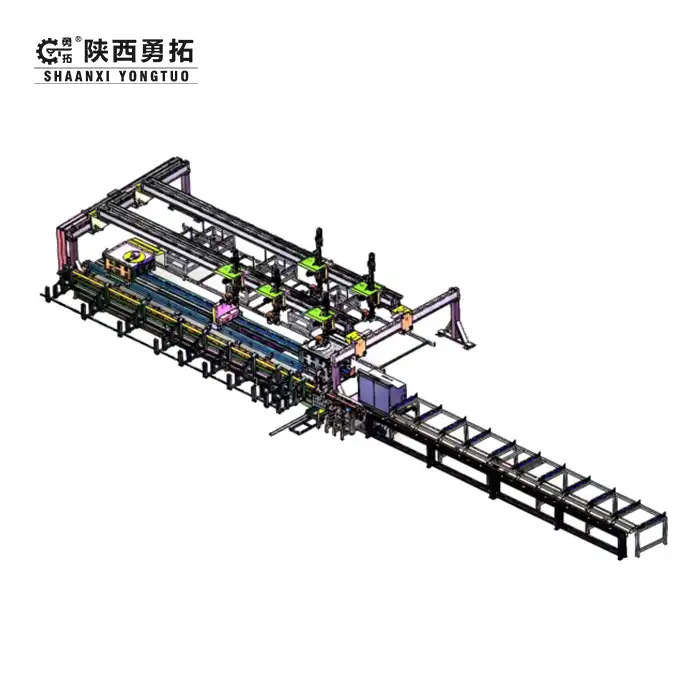

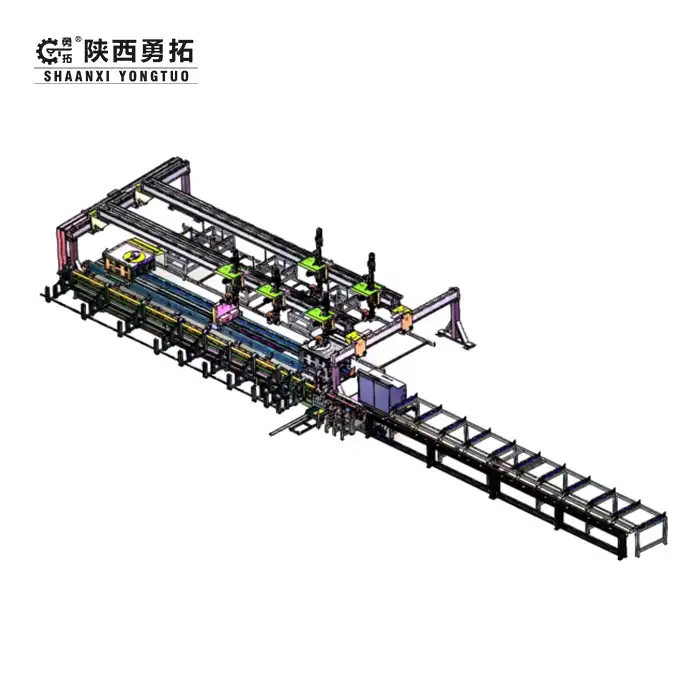

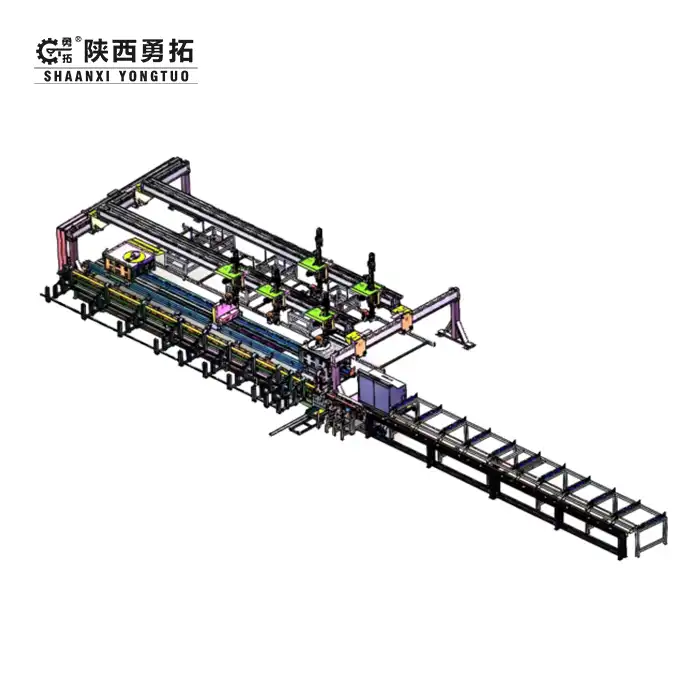

2.Equipped with three sets of three-axis robots for bending material feeding and finished product collection.

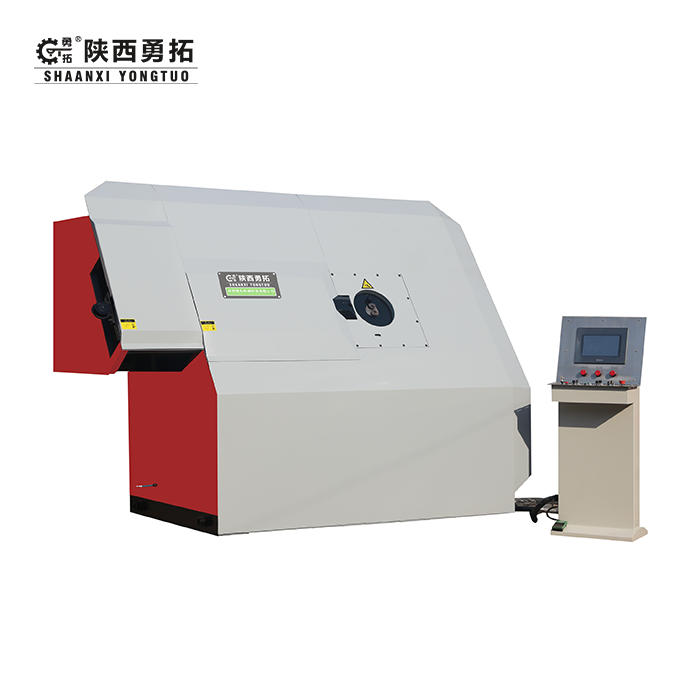

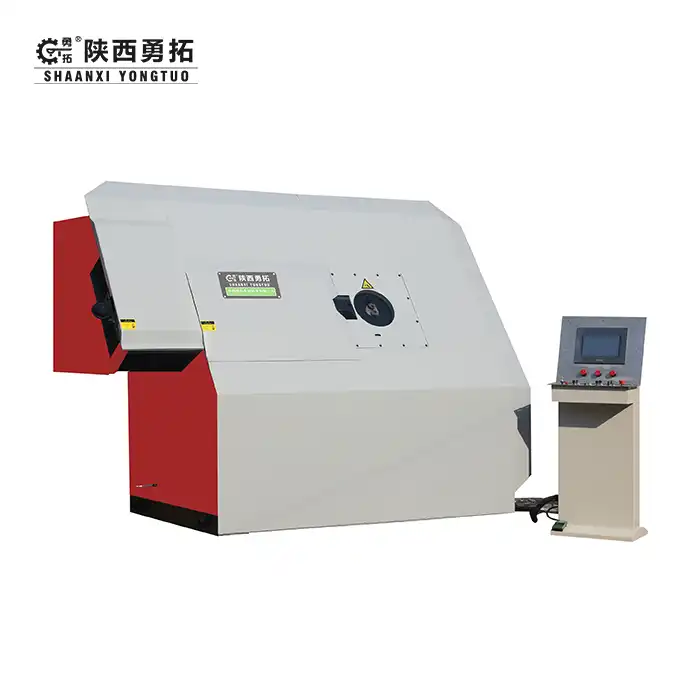

3.The bending rotation speed can be set arbitrarily, offering greater processing flexibility.

4.The planetary reducer is used for torque transmission during bending, ensuring low noise, highprecision,and long service life.

5.The middle clamping system uses a multi-piece flexible clamp, effectively securing multiple rebars and ensuring consistent dimensions for all processed rebars.

6.Optional automatic raw material feeding system is available, reducing the labor intensity of feeding operations."

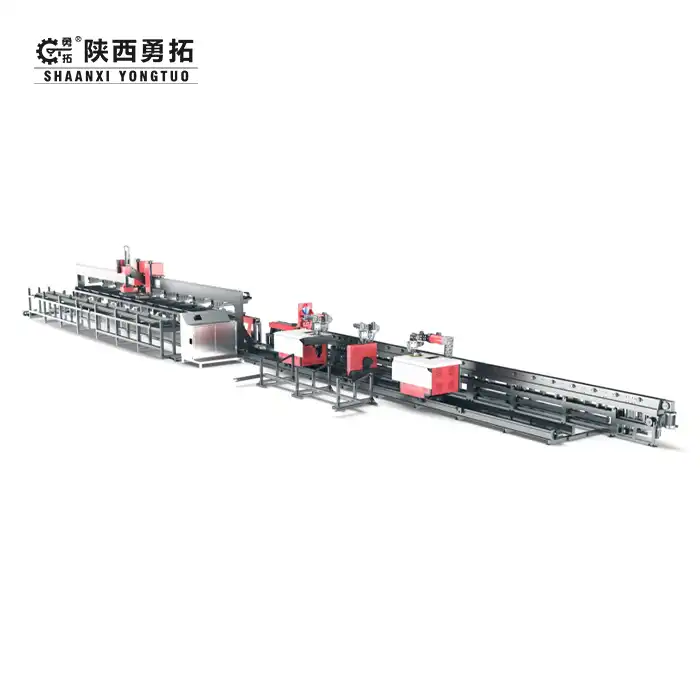

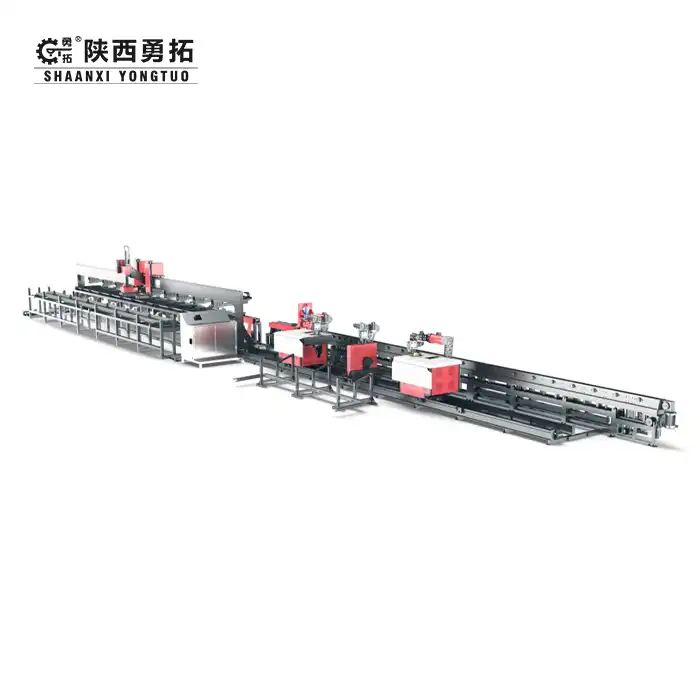

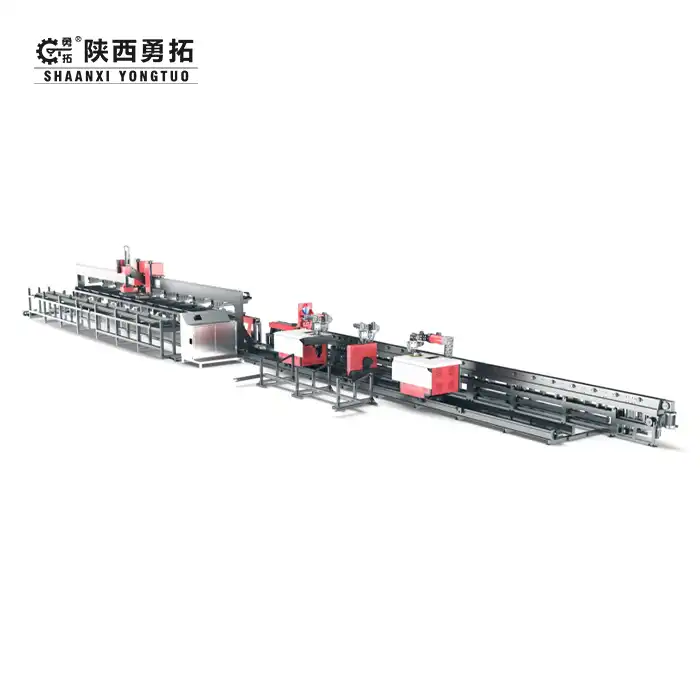

Bar Shearing and Bending Robot Production Line: Precision Automation for Modern Construction

Shaanxi Yongtuo Machinery Technology Co., Ltd, a leading Bar Shearing and Bending Robot Production Line manufacturer since 2003, delivers cutting-edge solutions for automated rebar processing. With 37 patents and a 20-year export history, our production line integrates feeding, cutting, bending, and collection into one seamless system, reducing labor costs by up to 70%.

Why Choose Yongtuo's product?

- ✅ Proven Expertise: ISO 9001-certified factory with 1,200+ global installations

- ✅ Full Automation: Replace 10–15 workers per shift with robotic material handling

- ✅ Energy Efficiency: 30% lower power consumption vs. traditional machines

- ✅ 24/7 Support: ≤12-hour故障响应时间 with remote diagnostics

- ✅ ROI Focus: Achieve payback in 12–18 months via reduced waste and downtime

Key Features & Advantages

- 🤖 Triple Robot System: 3-axis robots ensure precise feeding and finished product sorting

- 🔧 Smart Bending Control: Adjust rotation speed (0–360°) for complex shapes like seismic hooks

- 🛡️ Planetary Reducer: Noise ≤75dB with 10,000-hour maintenance-free operation

- 📐 Multi-Clamp System: Process 4–40mm rebars with ±0.5mm dimensional consistency

- 🌐 IoT-Ready: Optional data integration with ERP/MES for real-time monitoring

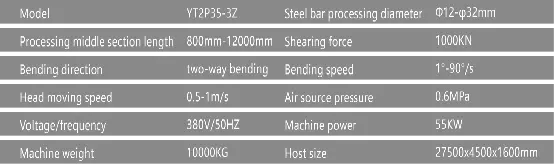

Technical Specifications

|

Applications

- Highway Bridges: Mass-produce reinforced concrete stirrups

- Wind Turbine Bases: Bend T20 rebars for anchor cages

- Prefab Housing: Automated production of wall reinforcement grids

- Shipbuilding: Process high-tensile steel for hull frames

Customization Options

- Material Feeding: Add conveyor belts for 12m-long rebar processing

- Software: Integrate BIM data for project-specific bending angles

- Safety: Laser guards or emergency stop configurations

Certifications

Our Bar Shearing And Bending robot production line hold prestigious CE, ISO 9001, and GOST - R certifications. The CE mark attests to our compliance with European safety, health, and environmental regulations. ISO 9001 validates our commitment to quality management systems. The GOST - R certification ensures our products meet Russian standards. Moreover, we strictly comply with ASTM A615 standards, guaranteeing top - notch quality for our offerings in the relevant industries.

After-Sales Service

When you choose our products, we provide free operator training to ensure seamless utilization. Our comprehensive 2 - year warranty gives you peace of mind against potential malfunctions. To further support your operations, we maintain a global spare parts network. With warehouses strategically located in the US, EU, and ASEAN regions, we can quickly supply the parts you need, minimizing downtime and keeping your equipment running smoothly.

Packaging

Our products are securely packaged in waterproof wooden crates, providing a robust outer shield against moisture during transit. Inside, shock - absorbent foam cushions the items, safeguarding them from jolts and impacts that could occur during shipping. To ensure seamless international shipping, we apply export - ready labeling. This labeling includes all necessary details such as product information, destination, and handling instructions, making the export process hassle - free.

About Shaanxi Yongtuo

Since our establishment in 2003, we have been a driving force in global infrastructure development. Our solutions have equipped projects across 60+ countries. Notably, we contributed to the Dubai Expo 2020, where our advanced technology helped create an unforgettable experience. We also played a crucial role in China's High - Speed Rail Network, powering its expansion and efficiency.

FAQ

Q: Can this line process deformed steel bar?

A: Yes! It handles ribbed/plain rebars up to HRB500 grade.

Q: What's the ROI timeline?

A: Most clients recover costs in 14 months via 50% labor reduction.

Q: How to handle power fluctuations?

A: Built-in voltage stabilizers protect against 380V±10% variances.

Q: Can I upgrade older models?

A: Ask about our retrofit kits for 2015–2020 machines.

Experience the Future of Rebar Processing

Join 500+ contractors who trust Yongtuo's Bar Shearing and Bending Robot Production Line. Request a quote today:

Optimize your workflow with Yongtuo – Where Innovation Meets Reliability.

YOU MAY LIKE

_1744680888628.png)