Top Features of an Automatic Bar Cutting Production Line

2025-04-27 10:40:36

Top Features of an Automatic Bar Cutting Production Line

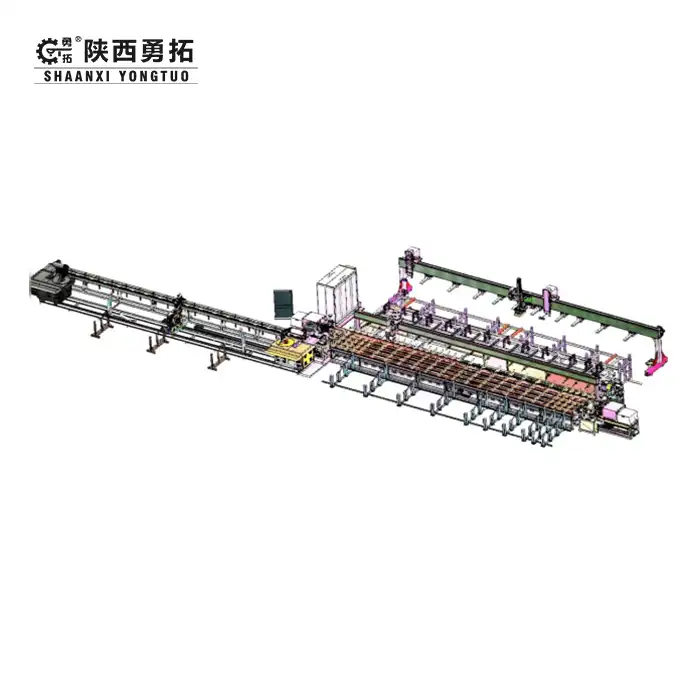

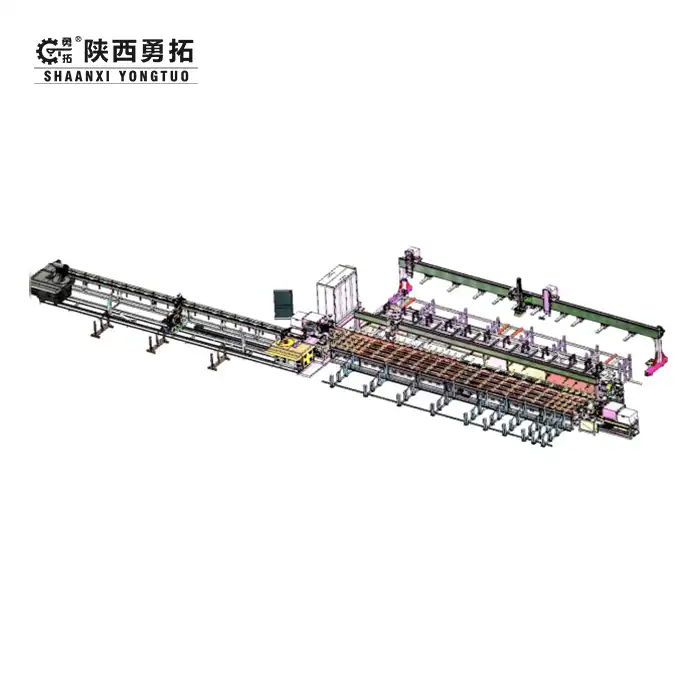

Modern construction and fabrication demands have transformed how steel reinforcement is processed, with the bar cutting production line emerging as an essential system for operations requiring volume, precision, and consistency. These advanced manufacturing systems integrate multiple processes—feeding, measuring, cutting, and collecting—into a synchronized workflow that dramatically outperforms traditional cutting methods. The core technology centers around servo-controlled measurement systems that guarantee dimensional accuracy within fractions of a millimeter, ensuring that each cut bar meets exact specifications required for structural integrity. The automation extends beyond mere cutting to include sophisticated material handling components such as chain-driven collection systems that minimize noise while efficiently sorting finished products by specification. With optional raw material loading devices that reduce manual labor requirements, modern automatic cutting lines create a comprehensive production environment that addresses multiple challenges facing steel fabricators and construction material suppliers. This integration of precision engineering, industrial automation, and material handling technologies delivers measurable advantages in production efficiency, material utilization, quality consistency, and workplace safety.

What Makes an Automated Bar Cutter Essential for Modern Workshops?

The transition from conventional cutting methods to automated systems represents more than technological progression—it addresses fundamental challenges confronting today's steel fabrication sector. The mounting pressure to deliver larger volumes of precisely cut materials within compressed timeframes has rendered traditional approaches increasingly inadequate.

Market Pressures Driving Automation Adoption

As construction deadlines shorten and project sizes grow, manual cutting operations struggle to meet increasing demands. Workshops equipped with bar cutting production line can handle orders that would otherwise require larger workforces or exceed practical capabilities. The labor market also presents a challenge, as skilled metalworkers become harder to recruit and more expensive to retain. Automated systems help address this by increasing productivity per worker while reducing physical strain from material handling. Additionally, competition in the fabrication sector is intensifying, with global markets pushing workshops to optimize operations. Those relying on traditional methods face disadvantages in pricing, delivery schedules, and quality consistency, making automation an essential strategy for survival.

Economic Analysis Beyond Initial Investment

Though the capital investment in a steel cutting line is significant, automation offers strong operational advantages. Labor costs can be reduced by 60-75% compared to manual cutting, and material savings of 3-5% are common due to the precision of automated systems, which minimize waste. These savings help offset the initial equipment cost. Furthermore, automation improves quality consistency, reducing dimensional variations that could lead to installation issues or rework. The indirect cost savings from improved quality often equal or exceed direct labor savings. Energy efficiency also plays a key role in reducing operational costs, with modern equipment using features like variable frequency drives and intelligent power management to optimize energy usage.

Production Planning Flexibility

The capacity to swiftly reconfigure cutting parameters provides workshops with unprecedented responsiveness to changing project requirements. Where manual operations require extensive setup adjustments when transitioning between specifications, automated systems permit rapid parameter changes through digital interfaces.

This adaptability proves particularly valuable for fabricators serving multiple projects simultaneously. The ability to intersperse different cutting specifications within production schedules without significant changeover delays allows more efficient resource utilization and improved deadline adherence.

Inventory management strategies shift dramatically with automation implementation. The responsiveness of these systems reduces requirements for extensive pre-cut inventory, allowing more just-in-time production approaches that minimize storage requirements and working capital allocation.

Precision Cutting, Zero Waste: Key Benefits of Automation

The advancement from approximation to exactitude characterizes the fundamental shift that bar cutting production line brings to reinforcement processing. This precision delivers cascading benefits throughout the construction supply chain, from material utilization to structural performance.

Measurement Systems: The Foundation of Cutting Accuracy

Modern cutting lines with servo-controlled measurement mechanisms offer positioning accuracy within ±0.5mm, ensuring precise alignment of structural components to engineering specifications, enhancing safety and durability. Unlike traditional methods that rely on operator judgment, automated systems eliminate dimensional variations, ensuring consistency across production runs. This is crucial for components like prefabricated reinforcement cages, where exact measurements are vital. Advanced feed systems feature continuous verification points to monitor material position and prevent errors, while calibration systems automatically adjust for dimensional drift, maintaining accuracy over time without manual intervention or production delays. This self-monitoring ensures consistent quality throughout extended operations.

Material Conservation Through Precision Management

Automation in cutting equipment leads to a 3-7% reduction in steel consumption for the same production output, driven by precise cuts that minimize overages and optimize cutting plans. This reduces material waste, such as end drops and unusable remnants, and eliminates rejections that would require replacement materials. Automated systems also collect scrap material efficiently, facilitating recycling or repurposing. The environmental impact is also significant, as improved material efficiency reduces the carbon footprint of steel production and transportation. While the primary benefits are economic, sustainability considerations are increasingly influencing equipment choices in construction projects.

Quality Consistency Across Production Volumes

Perhaps the most significant advantage lies in the elimination of fatigue-related quality variation from the manufacturing process. Where manual cutting operations typically show declining precision as production shifts progress, automated systems maintain consistent accuracy regardless of production duration or volume.

The structured collection systems incorporated into modern equipment contribute substantially to quality outcomes. The multi-position collection bins with chain-driven sorting mechanisms ensure cut materials remain organized by specification, preventing mixing errors that could otherwise occur during manual handling and sorting.

The implications of this quality consistency extend throughout the construction process. Field installation proceeds more efficiently when reinforcement components maintain exact dimensional specifications. Structural performance improves when reinforcement positioning achieves design intent precisely. Inspection processes simplify when components conform consistently to specifications.

Automatic Bar Cutting Lines: Speed, Safety & Smart Controls

The operational advantages of modern bar cutting production lines extend beyond precision to encompass production velocity, workplace safety, and intelligent control capabilities that transform overall workshop performance.

Production Throughput Transformations

Automated cutting systems enhance business capacity by processing 20-35 cuts per minute, far outpacing conventional methods that require multiple operators and stations. This speed advantage is amplified by continuous operation, eliminating interruptions from breaks or shift changes. Material handling innovations, such as automated feeding and collection systems, further boost throughput by removing delays and bottlenecks typical of manual processes. Integrated systems ensure smooth production flow with minimal disruption. Additionally, double-sided, three-position collection systems allow simultaneous processing of multiple specifications, enabling uninterrupted production for diverse projects with varying requirements. This seamless operation significantly increases efficiency and capacity.

Operator Safety and Ergonomic Advancements

Traditional cutting operations pose safety risks, such as cutting accidents and repetitive strain injuries from material handling. Automated systems reduce these hazards through physical guards, light curtains, and presence-sensing devices that stop operations if safety boundaries are breached. Automatic raw material loading devices also minimize physical strain, lowering the risk of injuries and operator fatigue, which can impact production quality. Additionally, noise reduction technologies, like steel chain collection systems, reduce impact noise during material handling, improving workplace comfort and supporting long-term hearing protection. These safety features significantly enhance operator protection and well-being.

Intelligent Controls and Operational Management

Modern cutting lines feature advanced digital control systems that enhance workflow efficiency. Intuitive interfaces simplify operation while providing tools for comprehensive production management. Pre-programmable cutting patterns allow for quick recall of frequent specifications, saving setup time. Real-time monitoring gives supervisors instant insights into production, material use, and progress, enabling proactive management. Maintenance systems provide alerts based on actual performance, optimizing preventive maintenance and reducing downtime. Additionally, integration with broader production management systems allows seamless data exchange with enterprise resources, offering improved visibility into material flow and production status. These features significantly enhance operational efficiency and decision-making.

Conclusion

The integration of a bar cutting production line into fabrication operations represents a transformative advancement with wide-ranging impacts across production capabilities. From direct benefits including increased precision, improved throughput, and enhanced safety to broader advantages such as material conservation and quality consistency, these systems fundamentally change what's possible in reinforcement processing.

As construction demands continue to intensify globally, the strategic advantage provided by advanced automation will likely become increasingly significant. Companies that have successfully implemented these systems report competitive advantages that extend beyond simple cost reduction to include enhanced service capabilities, improved quality reputation, and access to projects with demanding specifications or timelines.

For construction companies, precast manufacturers, steel fabricators, and infrastructure developers seeking to enhance their capabilities through advanced bar cutting technology, Shaanxi Yongtuo Machinery Technology Co., Ltd offers cutting-edge solutions with numerous competitive advantages. Their equipment features advanced technology, simple operation, energy efficiency, reliable performance, and excellent quality. For more information about these products, contact them at sxyongtuo@gmail.com.

References

1. International Association of Structural Steel Fabricators. (2023). Automation Technologies in Reinforcement Processing. Technical Publication Series, Volume 8.

2. Zhang, L. & Chen, H. (2024). Production Efficiency Analysis of Automated Cutting Systems in Construction Material Preparation. Journal of Construction Engineering, 42(2), 87-102.

3. American Society of Civil Engineers. (2023). Quality Impact of Fabrication Precision on Reinforced Concrete Structures. ASCE Technical Report 2023-05.

4. Singh, R. & Patel, J. (2024). Economic Assessment of Automation Technologies in Steel Processing. Industrial Economics Review, 16(3), 112-128.

YOU MAY LIKE

_1744680888628.png)