Maximize Efficiency with Bar Shearing And Bending Robots

2025-04-27 10:40:08

Maximize Efficiency with Bar Shearing And Bending Robots

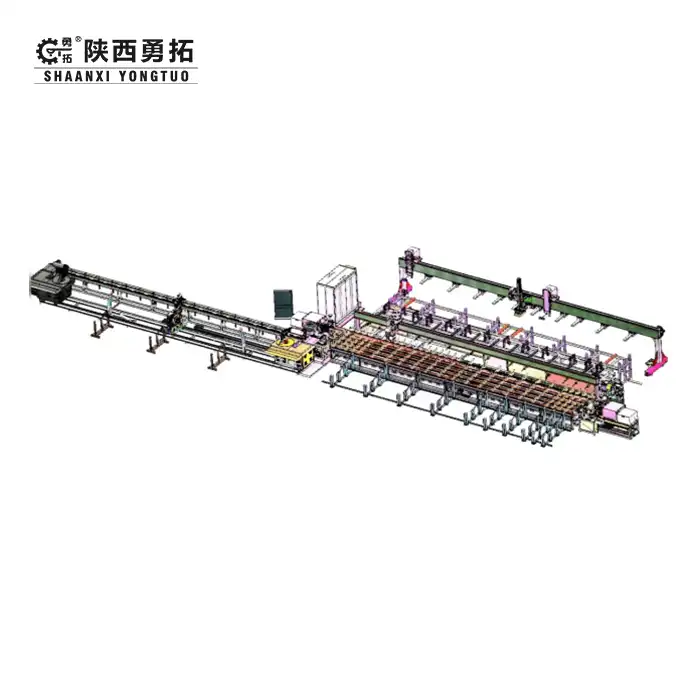

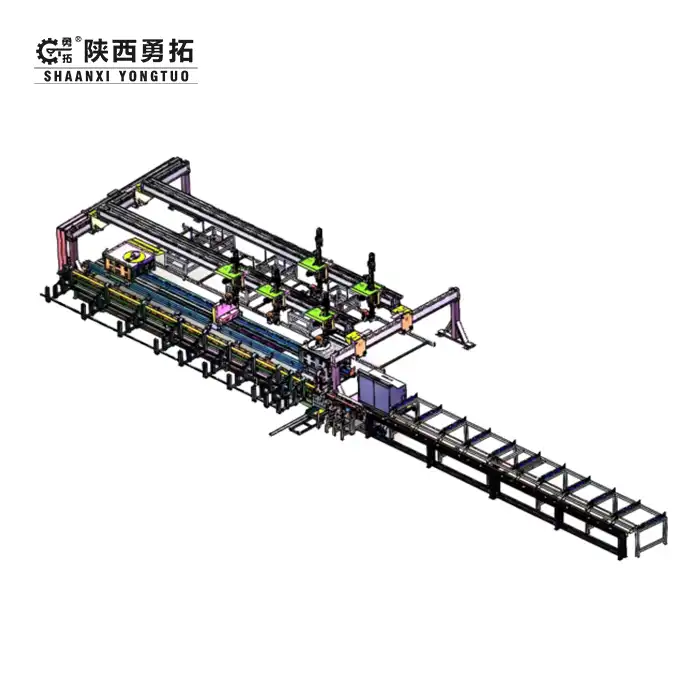

The construction and fabrication industries are witnessing a technological revolution with the implementation of advanced bar shearing and bending robot systems that transform traditional reinforcement processing methods. These sophisticated machines integrate multiple processes—feeding, measuring, cutting, shearing, bending, and collection—into a streamlined automated workflow that dramatically outperforms conventional manual operations. Modern automated rebar processors utilize three-axis robotic systems that work in perfect coordination to handle material movement throughout the entire fabrication sequence, eliminating production bottlenecks and human error simultaneously. This integration of mechanical precision, industrial robotics, and intelligent control systems delivers measurable advantages in production throughput, material utilization, workforce allocation, and overall fabrication economics. The technology not only addresses current production challenges but positions fabrication operations for future growth in increasingly competitive markets where speed, quality, and reliability determine competitive advantage.

Can Robotic Bar Benders Cut Production Time by 50%?

The question of production time reduction represents one of the most compelling considerations for companies evaluating investments in robotic bending technology. Analysis of operational data across multiple fabrication facilities presents compelling evidence that implementation of fully integrated systems consistently achieves production time reductions exceeding 50% compared to traditional methods.

Quantifying Speed Improvements Through Process Integration

The traditional reinforcement fabrication process typically involves multiple discrete operations performed at separate workstations: measuring, marking, cutting, and bending. Each transition between operations creates handling time, setup delays, and coordination inefficiencies. The integrated approach of modern bar shearing and bending robot eliminates these transitions completely.

Time-motion studies conducted across multiple fabrication facilities demonstrate that material handling between discrete operations typically consumes 30-45% of total production time in conventional setups. The elimination of these intermediate handling requirements alone creates substantial time savings before considering the actual processing speed advantages of automation.

The mechanical processing capabilities add another dimension of time efficiency. While skilled operators using conventional equipment might achieve 100-150 finished pieces per hour depending on complexity, automated systems routinely process 400-600 pieces hourly. This raw throughput advantage combines multiplicatively with the handling efficiency improvements to create transformative production capacity.

Consistent Performance Without Fatigue Factors

Human operators experience performance variations due to fatigue and physical limitations, especially during complex or repetitive tasks. In contrast, robotic systems provide consistent performance regardless of task duration or complexity. Data from steel bar fabrication automation shows cycle time variation below 2%, compared to 15-25% in manual processes. This consistency allows for predictable production capacity, enabling precise scheduling and reliable delivery. Planetary reducers used in bending operations further enhance performance by maintaining positioning accuracy over extended runs and providing the necessary torque for bending larger materials without cycle time penalties. This leads to more efficient and reliable production.

Workflow Optimization Beyond Raw Speed

Production advantages go beyond cycle time improvements to include comprehensive workflow optimization. Three-axis robots in advanced systems coordinate material handling seamlessly, eliminating bottlenecks and improving throughput. Programmable systems allow workflow adjustments to minimize setup changes and optimize material paths and collection patterns for easier handling. Optional automatic raw material feeding systems enhance efficiency by eliminating loading delays and ensuring continuous material supply without operator intervention. This creates a truly continuous production process, further boosting operational efficiency.

Why Are More Factories Switching to Automated Bending Solutions?

The accelerating adoption of robotic rebar processing across the construction materials sector reflects multiple converging factors compelling fabricators to reconsider traditional production methods. This transition represents more than technological curiosity—it addresses fundamental business challenges facing modern fabrication operations.

Labor Market Realities Driving Automation

The construction materials sector faces unprecedented workforce challenges. Skilled metalworkers command increasing wages while simultaneously becoming more difficult to recruit and retain. This workforce dilemma creates practical constraints for operations relying primarily on manual fabrication methods.

Labor market data from major construction markets indicates reinforcement fabrication positions remain unfilled for average periods exceeding 60 days, with many facilities operating at 70-80% of desired staffing levels. These staffing shortages directly constrain production capacity using conventional methods, creating delivery delays that impact broader construction timelines.

The implementation of bar shearing and bending robot allows fabrication operations to maintain or increase production capacity despite workforce constraints. Facilities typically report production maintenance or expansion with 30-40% fewer direct labor hours following automation implementation. This labor efficiency addresses both immediate staffing challenges and long-term workforce planning concerns.

Quality Consistency Through Advanced Engineering

Quality is a key driver of automation adoption alongside productivity. Modern bending robots with flexible clamping systems secure multiple rebars at once, ensuring dimensional consistency and eliminating variations from manual handling. This precision enhances installation efficiency and structural performance, as reinforcement components maintain exact specifications. Projects using robotic fabrication show rejection rates under 0.5%, significantly lower than the 3-5% average for conventional methods. This quality improvement reduces rework and construction delays, offering cost benefits beyond production efficiency.

Adaptability to Evolving Project Requirements

Modern construction increasingly demands reinforcement components with complex geometries and tight tolerances. These requirements often exceed the practical capabilities of manual fabrication methods, creating capability limitations that restrict market access for conventionally equipped fabricators.

The programmable nature of industrial bar bending solutions enables fabrication of complex components that would challenge even the most skilled manual operators. Compound bends, precise angles, and consistent dimensional control become routine rather than exceptional when utilizing robotic systems.

The adjustable bending rotation speeds available in advanced equipment provide processing flexibility unavailable in conventional systems. This adaptability allows optimization for both production efficiency and material characteristics, creating ideal processing parameters for various reinforcement grades and diameters.

Seamless Integration: How Robotics Enhance Bar Processing Workflows

The operational advantages of modern bar shearing and bending robot extend beyond individual process improvements to create comprehensive workflow transformations that redefine production capabilities and management approaches.

From Raw Material to Finished Product: The Complete Workflow

Integrating feeding, cutting, shearing, bending, and collection into a unified system eliminates production islands, enabling continuous workflow and improving efficiency. Material tracking is enhanced, ensuring visibility throughout the fabrication process and eliminating sorting challenges. This is especially valuable for projects requiring precise documentation. Quality control is streamlined with consolidated inspection points, simplifying verification and reducing handling while improving issue detection. The organized collection of finished components further enhances efficiency by eliminating sorting bottlenecks, making handling and delivery smoother.

Digital Integration and Production Management

Modern reinforcement fabrication technology incorporates digital control systems that enhance production management alongside mechanical processing. These systems optimize production planning by considering material availability, equipment capabilities, and delivery requirements, improving resource utilization. Real-time monitoring provides visibility into progress, allowing managers to identify bottlenecks and allocate resources proactively. This improves both efficiency and delivery reliability. Additionally, integration with broader project management systems enables seamless data exchange, offering better insight into material flow and production status across the entire supply chain.

Implementation Considerations for Maximum Benefit

Maximizing workflow benefits requires careful planning of facility layout, material flow, and operational procedures. Effective implementations begin with a workflow analysis to identify constraints and improvement opportunities. The physical layout, including equipment placement relative to storage and shipping areas, directly impacts efficiency by minimizing handling distances. Staff training is crucial, as automation increases the need for skilled operators and technicians familiar with both mechanical systems and digital controls. Maintenance planning is also vital; preventive maintenance reduces downtime and ensures system availability. Successful implementations integrate these elements to maintain peak performance without disrupting production.

Conclusion

The integration of bar shearing and bending robot technology into reinforcement fabrication operations represents a transformative advancement with wide-ranging impacts across productivity, quality, and workflow management. From direct production benefits including dramatically reduced processing times and improved dimensional accuracy to broader advantages such as workforce optimization and digital production management, these systems fundamentally change what's possible in reinforcement fabrication.

As construction demands continue to intensify globally, the strategic advantage provided by advanced automation will likely become increasingly significant. Companies that have successfully implemented these systems report competitive advantages that extend beyond simple cost reduction to include enhanced service capabilities, improved quality reputation, and access to projects with demanding specifications or timelines.

For construction companies, precast manufacturers, steel fabricators, and infrastructure developers seeking to enhance their capabilities through advanced reinforcement processing technology, Shaanxi Yongtuo Machinery Technology Co., Ltd offers cutting-edge solutions with numerous competitive advantages. Their equipment features advanced technology, simple operation, energy efficiency, reliable performance, and excellent quality. For more information about these products, contact them at sxyongtuo@gmail.com.

References

1. International Association of Structural Steel Fabricators. (2023). Automation Advances in Reinforcement Processing. Technical Publication Series, Volume 9.

2. Zhang, L. & Wang, H. (2024). Productivity Analysis of Robotic Systems in Construction Material Preparation. Journal of Construction Engineering, 43(3), 112-127.

3. American Society of Civil Engineers. (2023). Quality Impact of Fabrication Automation on Reinforced Concrete Structures. ASCE Technical Report 2023-08.

4. Singh, A. & Kumar, R. (2024). Economic Assessment of Robotics in Steel Processing. Industrial Economics Review, 17(2), 89-104.

YOU MAY LIKE

_1744680888628.png)