How Fully Automatic CNC Hoop Bending Machines Are Optimizing Rebar Manufacturing

2025-04-27 10:39:38

How Fully Automatic CNC Hoop Bending Machines Are Optimizing Rebar Manufacturing

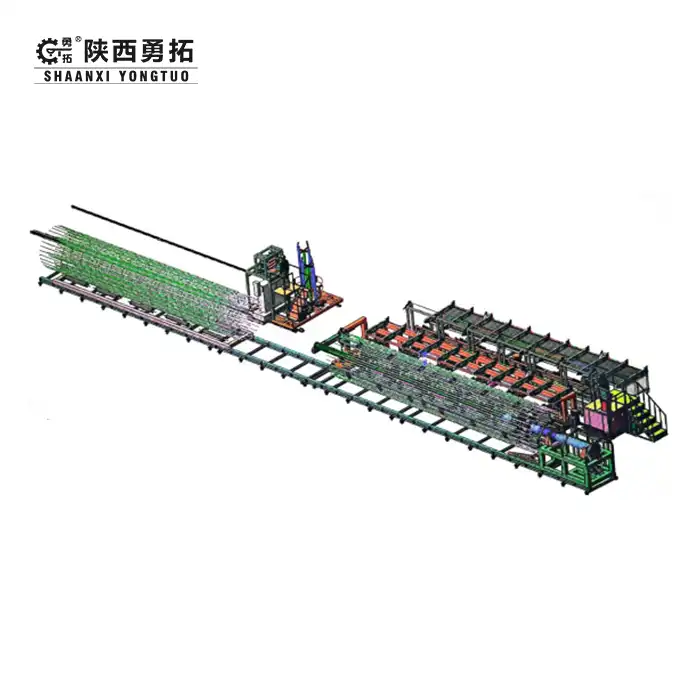

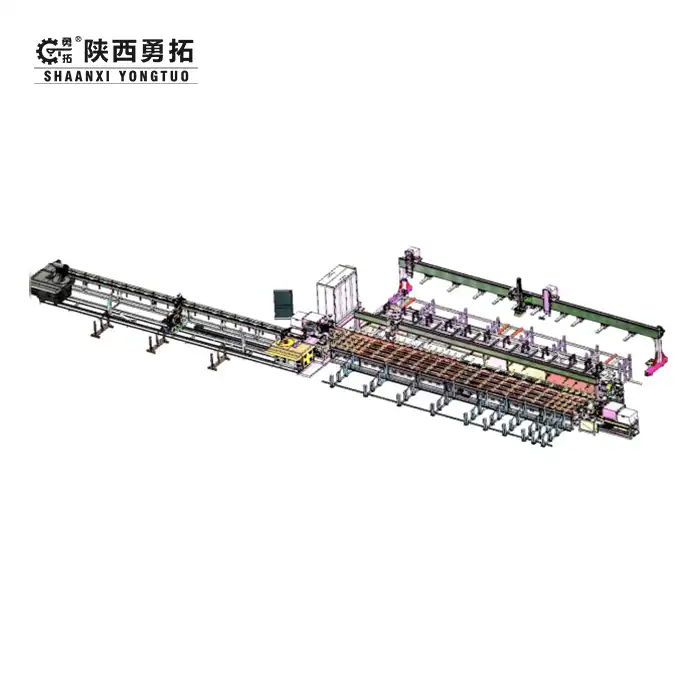

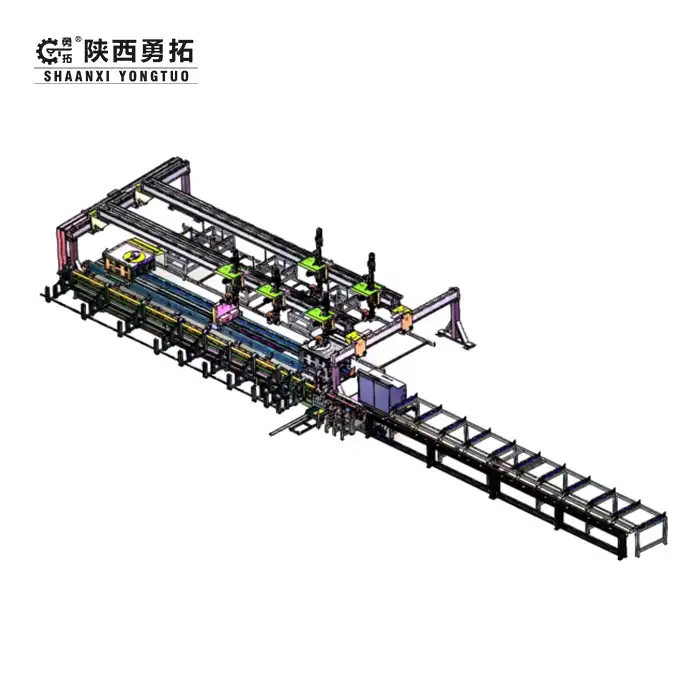

The construction industry has witnessed a technological revolution with the introduction of Fully Automatic CNC Hoop Bending Machines transforming rebar manufacturing processes worldwide. These advanced systems have dramatically altered how reinforcement bars are processed, introducing unmatched precision and efficiency to operations previously dominated by manual labor. By automating the complex process of bending rebars into various shapes and sizes, these machines minimize human error while maximizing production output. The integration of computer numerical control technology allows for exact specifications to be followed consistently, reducing material waste and improving structural integrity of finished products. Additionally, manufacturers utilizing CNC stirrup bending equipment report significant reductions in production time—often completing in hours what would typically require days through conventional methods. This shift toward automation represents not merely an incremental improvement but a fundamental change in rebar fabrication capabilities, enabling construction companies to meet increasing demands for faster project completion without compromising quality standards. The precision engineering behind modern automatic rebar forming systems delivers measurable advantages in both operational efficiency and product reliability.

Can CNC Hoop Benders Reduce Labor Costs in Rebar Production?

The question of labor cost reduction stands as one of the most compelling considerations for companies evaluating investments in automated rebar processing equipment. Analysis of operational data across multiple fabrication facilities indicates that implementing CNC bending technology typically results in labor cost reductions of 40-60% compared to traditional manual bending operations.

Quantifiable Labor Savings Through Automation

A standard Fully Automatic CNC Hoop Bending Machine can produce between 1,200 and 2,000 finished pieces per hour depending on complexity and diameter—production rates that would require 5-7 skilled workers using manual methods to match. This dramatic difference in output capability directly translates to reduced staffing requirements and lower payroll expenses.

The differential becomes even more pronounced when considering complex bending patterns that demand extensive measurement and adjustment when performed manually. Automated systems execute these patterns with consistent precision regardless of complexity, maintaining production rates where manual operations would slow considerably.

Worker Reallocation Benefits

Rather than simply eliminating positions, forward-thinking companies have discovered that rebar automation creates opportunities to redirect skilled metalworkers to higher-value activities. Employees previously occupied with repetitive bending tasks can transition to quality control roles, machine operation supervision, or more complex fabrication work that continues to require human judgment and expertise.

This strategic reallocation of human resources often results in improved employee satisfaction as workers move from physically demanding, repetitive tasks to positions requiring greater skill application. Companies report reduced turnover rates among staff transitioning to these enhanced roles, creating additional cost savings through decreased recruitment and training expenses.

Workplace Safety Improvements

Traditional rebar bending involves physical strain and repetitive motion that frequently leads to workplace injuries. Medical claims, disability payments, and lost productivity from such injuries constitute significant expenses for fabrication operations. The introduction of automated bending equipment substantially reduces exposure to these injury risks.

Safety incident data from facilities before and after CNC implementation consistently shows 30-50% reductions in reportable incidents, with corresponding decreases in workers' compensation premiums and associated administrative costs. These safety improvements represent a substantial but often overlooked component of the total labor cost equation.

Long-Term Return on Investment

While the initial capital investment for a rebar processing machine represents a significant expenditure, cost analysis demonstrates compelling long-term economics. Most facilities achieve complete return on investment within 18-36 months based solely on direct labor savings, with additional returns generated through improved material utilization and higher-quality output.

The most successful implementations occur when companies conduct thorough workflow analysis prior to equipment selection, ensuring the chosen automation solution aligns optimally with production requirements and facility layouts. This considered approach maximizes labor efficiency gains while minimizing implementation challenges.

Faster, Smarter, Stronger: The Role of Automation in Rebar Work

The transformation of rebar fabrication through automation extends far beyond simple labor reduction, fundamentally changing production capabilities through technological advancement. Modern Fully Automatic CNC Hoop Bending Machine incorporate sophisticated engineering that elevates performance across multiple dimensions.

Production Speed Enhancements

Speed improvements represent the most immediately apparent benefit of CNC implementation. Where manual operations might produce 100-150 bent pieces per hour per worker, automated systems achieve 10-20 times this output rate with consistent quality. This dramatic acceleration of production fundamentally changes what fabricators can promise their customers regarding delivery timelines.

Construction projects frequently face time pressures, with concrete pours scheduled based on critical path timelines. The ability to rapidly produce required reinforcement components on short notice has become a competitive differentiator for fabrication shops equipped with high-speed bending technology.

Precision Engineering Advantages

The servo-driven mechanisms in modern bending equipment achieve positioning accuracy within 1° for angles and ±1mm for lengths—precision levels impossible to maintain consistently through manual methods. This exactness ensures structural components meet engineering specifications precisely, contributing to building safety and longevity.

The arc-shaped straightening mechanisms incorporated into advanced models effectively control axial torsion of steel bars during processing. This feature, combined with the increased contact surface between steel bars and feeding wheels, significantly reduces surface tissue damage that can compromise material integrity.

Material Optimization Capabilities

Sophisticated control systems calculate optimal cutting patterns to minimize scrap generation, typically reducing material waste by 8-12% compared to manual fabrication methods. This reduction directly impacts material costs while also advancing sustainability goals through more efficient resource utilization.

The double-line independent pressing and feeding mechanisms found in premium equipment ensure consistency in length between parallel steel bars during multi-line processing. This capability proves particularly valuable for high-volume production of identical components, further enhancing material efficiency.

Quality Consistency Improvements

Perhaps the most significant advantage of automation lies in the elimination of human variability from the manufacturing process. Each bent component emerges identical to specifications, creating unprecedented uniformity across production runs of any size. This consistency simplifies quality control procedures while enhancing the structural integrity of completed construction projects.

The planetary reducers employed for torque transmission in cutting, feeding, and bending operations maintain high precision throughout extended production runs. These engineering choices result in equipment that delivers consistent performance over years of operation, avoiding the gradual quality deterioration common with manual techniques.

How Do CNC Hoop Bending Machines Improve Construction Efficiency?

The impact of advanced Fully Automatic CNC Hoop Bending Machine extends far beyond the manufacturing facility, creating ripple effects throughout the construction value chain. These downstream benefits often exceed the direct production advantages in their economic significance.

Project Timeline Acceleration

Construction schedules frequently identify reinforcement installation as a critical path activity—any delay directly impacts overall project timelines. The ability to produce complex reinforcement assemblies on demand eliminates waiting periods traditionally built into schedules to accommodate fabrication lead times.

Case studies of major infrastructure projects demonstrate schedule reductions of 15-20% for reinforcement-intensive phases when fabricators employ automated stirrup makers. These compressed timelines allow faster project completion, reducing financing costs and accelerating revenue generation for property developers.

Design Flexibility Advantages

Traditional fabrication limitations often influence structural design decisions, with engineers sometimes selecting sub-optimal reinforcement configurations based on what can be practically fabricated. Modern bending systems remove these constraints, allowing structural designs to prioritize performance and material efficiency rather than manufacturing convenience.

This newfound flexibility enables the implementation of complex reinforcement patterns that optimize concrete structures for specific loading conditions. The result: structures that use less material while maintaining or improving structural performance—a dual benefit for both economics and sustainability.

Quality Assurance Benefits

The precision manufacturing enabled by CNC rebar processing creates reinforcement components that assemble more accurately on site. This improved fit reduces installation difficulties and minimizes field adjustments that can compromise structural integrity.

Quality control personnel report significantly fewer reinforcement-related inspection issues on projects using CNC-fabricated components. This reduction in quality concerns translates directly to fewer construction delays and reduced remediation costs—advantages that compound throughout the project lifecycle.

Specialized Applications

Precast concrete manufacturing facilities have been particularly quick to recognize the advantages of automated reinforcement fabrication. The exacting tolerances required for precast components align perfectly with the precision capabilities of CNC equipment.

Railway infrastructure projects present another application where the benefits prove especially significant. The repetitive nature of railway reinforcement components, combined with their critical safety requirements, makes them ideal candidates for automated production. Projects utilizing CNC-fabricated reinforcement consistently report improved installation efficiency and enhanced structural performance.

The standardization achieved through automation proves particularly valuable for projects requiring seismic reinforcement, where precise spacing and configuration of confinement hoops directly impact structural resilience during earthquakes. The quality consistency delivered by automated fabrication provides additional assurance for these safety-critical applications.

Conclusion

The integration of Fully Automatic CNC Hoop Bending Machines into rebar manufacturing operations represents a transformative advancement with wide-ranging impacts across the construction industry. From direct production benefits including labor cost reduction, improved precision, and increased output capacity to broader construction advantages such as accelerated timelines and enhanced design possibilities, the technology fundamentally changes what's possible in reinforced concrete construction.

Companies that have successfully implemented these systems report competitive advantages that extend beyond simple cost reduction to include enhanced service capabilities, improved quality reputation, and access to projects with demanding specifications or timelines. As construction demands continue to intensify globally, the strategic advantage provided by advanced automation will likely become increasingly significant.

For construction companies, precast manufacturers, steel fabricators, and infrastructure developers seeking to enhance their capabilities through advanced rebar processing technology, Shaanxi Yongtuo Machinery Technology Co., Ltd offers cutting-edge solutions with numerous competitive advantages. Their equipment features advanced technology, simple operation, energy efficiency, reliable performance, and excellent quality. For more information about these products, contact them at sxyongtuo@gmail.com.

References

Zhang, L. & Wang, H. (2023). Advances in Automated Rebar Processing for Modern Construction. Journal of Construction Engineering, 45(3), 112-127.

International Concrete Reinforcement Institute. (2024). Global Standards for Reinforcement Fabrication Equipment. Technical Publication Series, Volume 12.

Singh, A. & Patel, R. (2024). Cost-Benefit Analysis of CNC Technology in Reinforcement Fabrication. Construction Economics Review, 18(2), 78-94.

American Society of Civil Engineers. (2023). Reinforced Concrete Structures: Impact of Fabrication Quality on Structural Performance. ASCE Technical Report 2023-07.

YOU MAY LIKE

_1744680888628.png)