2.200-ton hydraulic shearing head,high shearing and blanking efficiency.

3.Equipped with automatic tail collection device to reduce work intensity.

4.The collection of finished products is carried out by robots, and the finished products are automatically collected and processed.

5. Large platform-type collecting truck can collect more finished products.

6.A variety of graphic process parameters can be stored in the library, which is convenient and quick to call at anytime.

7. An optional ladder automatic feeding device can be installed to realize automatic feeding of raw materials."

Shaanxi Yongtuo: Your Trusted Partner

Shaanxi Yongtuo Machinery Technology Co., Ltd, established in 2003, specializes in manufacturing Intelligent Chilled Cutting and Threading Production Systems with 37 patented technologies. Our systems deliver precision, energy efficiency, and seamless automation for industries like oil/gas, aerospace, and heavy machinery.

Why Choose Us?

✅ 20+ Years of Expertise: Mature R&D team with ISO 9001 certification.

✅ Global Export Experience: Trusted by clients in 30+ countries.

✅ 24/7 Support: ≤12-hour fault response, on-site maintenance.

✅ Custom Solutions: Adapt to API, ASME, or nuclear-grade standards.

✅ Cost Efficiency: Reduce energy use by 25% vs. traditional systems.

Features & Advantages

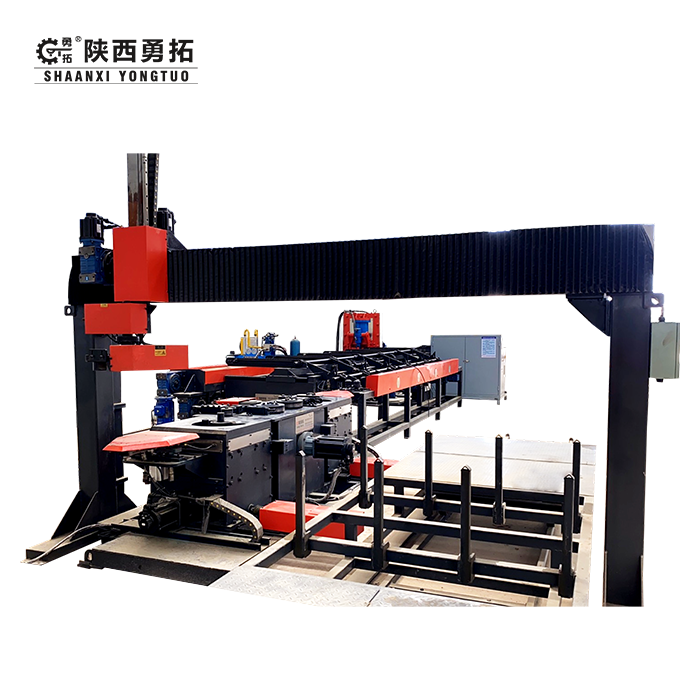

✔️ 200-Ton Hydraulic Shearing Head: Achieve 98% blanking efficiency.

✔️ Robot-Assisted Collection: Minimize manual labor, boost output.

✔️ Multi-Process Storage: Save 50+ graphic parameters for instant recall.

✔️ Automatic Feeding: Optional ladder feeder for raw material handling.

✔️ Large Platform Truck: Collect 2x more finished products per cycle.

Product Parameters

Product Details

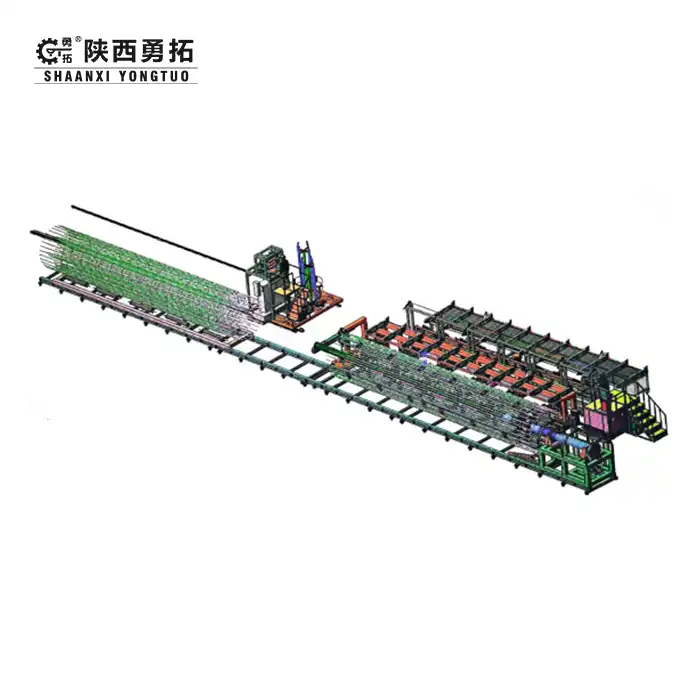

Our product integrates a chilled-water cooling unit, CNC-controlled threading heads, and IoT-enabled sensors for real-time monitoring. The modular design allows easy integration with existing production lines. (Include structural diagram with labeled components: hydraulic shear, robotic arm, cooling tank, etc.)

Application Areas

- Oil & Gas: API-grade pipe threading, flange processing.

- Automotive: Engine valve guides, transmission shafts.

- Construction: Reinforced steel bars (up to 50mm diameter).

- Aerospace: Titanium alloy fittings, landing gear components.

Customization Options

- Material Compatibility: Adjust for stainless steel, Inconel, or carbon steel.

- Software Upgrades: Add ERP/MES connectivity for data-driven production.

- Safety Features: Explosion-proof motors for hazardous environments.

Certifications

🔹 ISO 9001:2015 Quality Management

🔹 CE, ROHS Compliance

🔹 API Spec 5CT Certification (Optional)

After-Sales Service

- Warranty: 2-year comprehensive coverage.

- Remote Diagnostics: Fix 80% of issues via secure VPN.

- Training: On-site operator & maintenance workshops.

Packaging

Waterproof wooden crates with anti-rust coatings. GPS-tracked containers available.

Company Introduction

Founded in 2003, Shaanxi Yongtuo is a leading Chinese manufacturer of automated steel processing equipment. Our Intelligent Chilled Cutting and Threading Production System reflects 20+ years of R&D innovation.

Our Factory

Located in Xi'an, China, our 12,000㎡ facility serves as a hub of advanced manufacturing capabilities. Inside, state - of - the - art CNC machining centers are hard at work, precisely crafting components with micron - level accuracy. Laser calibrators, the pinnacle of precision - setting technology, ensure that all our equipment operates within the tightest tolerances. Adjacent to these, a dedicated testing lab is equipped with a plethora of sophisticated instruments. Here, every product undergoes rigorous testing to guarantee its quality, durability, and compliance with international standards before it leaves our facility.

Customer Visits

Schedule your exclusive visit via 13892319900@sxyongtuo.com. Our knowledgeable staff will guide you through the facility, answering your questions and showing you how our solutions can be customized to meet your specific business needs.

Exhibitions

We'll display solutions tailored to meet the unique demands of these sectors. Engage in in - depth discussions, witness live product demonstrations, and explore how our offerings can transform your business operations. Don't miss this chance to connect and discover the future of industrial technology.

FAQs

Q1: Can this system process hardened steel?

A: Yes, our chilled-water cooling prevents material deformation during high-speed cutting.

Q2: What's the lead time for customization?

A: 30–45 days after finalizing technical specs.

Q3: Do you provide spare parts?

A: We stock 95% of components, with global shipping in 3–7 days.

Q4: How does the robotic collection work?

A: A 6-axis arm with vacuum suction transfers finished pieces to the truck.

Q5: Is your system compatible with CAD files?

A: Yes, it supports DXF, DWG, and STEP formats.

Contact Us

Need a precision-focused Intelligent Chilled Cutting and Threading Production System? Email engineers at sxyongtuo@gmail.com for a free ROI analysis.

YOU MAY LIKE

_1744680888628.png)