2.The reducer adopts planetary reducer, which has high transmission accuracy and long service life.

3.The gear is made of 20CrMnTi material, with a carburizing hardness of HRC58-62 and a longer service life.

4.The arc rolling wheel is made of Cr12MoV mold steel, with a vacuum quenching hardness of HRC58-62 and is durable.

5. Heightened driving wheel design can process multiple steel bars at one time.

6. The hand wheel reducer drives the arc pressing wheel, which is easy and quick to operate.

7. Double support panels control the stability of rolling arcs of multiple steel bars.

8.Thickened panel increases equipment stability."

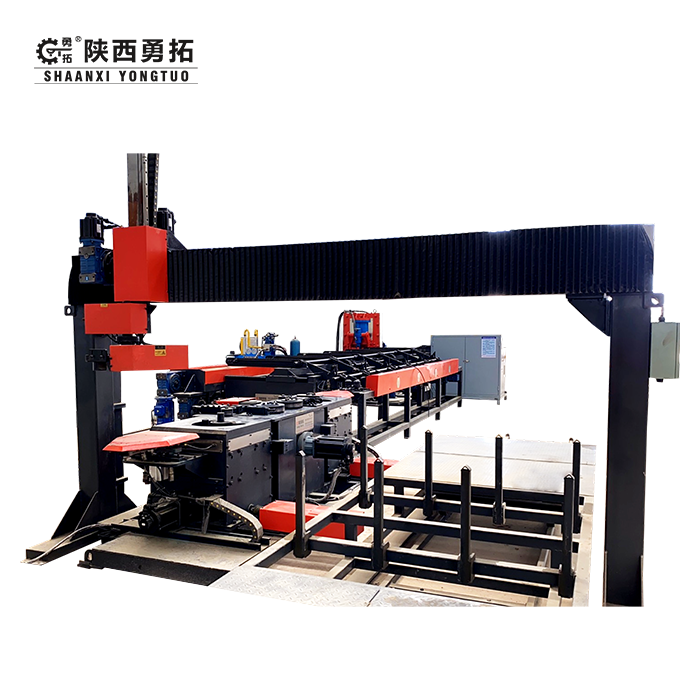

Shaanxi Yongtuo Machinery: Your Trusted Reinforcing Steel Crooking Machine Partner

Since 2003, Shaanxi Yongtuo Machinery Technology Co., Ltd has delivered innovative Reinforcing Steel Crooking Machines trusted by global clients. With 37 patents, a mature R&D team, and ISO-certified production, we combine advanced technology with 24/7 support to ensure unmatched reliability.

Why Choose Our product?

✅ 20+ Years of Expertise: Proven solutions for bridges, tunnels, and prefab construction.

✅ Energy-Efficient Design: 11KW variable frequency motor reduces power consumption by 15%.

✅ Durable Components: Planetary reducer + 20CrMnTi gears (HRC58-62 hardness) for 50,000+ operational hours.

✅ Global Compliance: CE, ISO, and GB/T 27695-2011 certified.

✅ Rapid Support: ≤12-hour fault response domestically, 24-hour remote diagnostics.

Key Features & Advantages

- Adjustable Speed Control: 11KW motor enables flexible bending speeds (5-25 RPM).

- Cr12MoV Arc Wheels: Vacuum-quenched rollers withstand high-pressure bending without wear.

- Multi-Bar Processing: Heightened driving wheels bend 6-8 steel bars simultaneously.

- Dual Support Panels: Ensure stability during heavy-duty operations.

- Hand Wheel Reducer: Simplifies adjustments, reducing setup time by 30%.

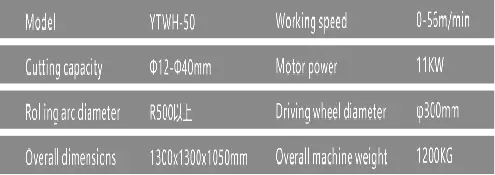

Technical Parameters

Application Areas

Our Reinforcing Steel Crooking Machine is ideal for:

- High-rise buildings & bridge construction.

- Railway/road infrastructure projects.

- Wind turbine base fabrication.

- Metal fabrication workshops.

Customization Options

Tailor your machine with:

- IoT-enabled monitoring systems.

- Custom bending angles (30°-180°).

- Multi-language interfaces.

Certifications

✔️ ISO 9001:2015

✔️ CE Certification

✔️ GB/T 27695-2011 Compliance

After-Sales Service

- 1-year warranty + lifetime technical support.

- Global spare parts network.

- On-site training included.

Packaging & Shipping

Our export - ready wooden crates are engineered to perfection, featuring top - tier waterproofing and shock - absorption capabilities. The outer layer of the crates is treated with a high - performance waterproof coating that can withstand rain, humidity, and even splashes during transit. Inside, thick layers of shock - absorbing materials, such as dense foam or specially designed cushioning pads, are carefully placed. This setup safeguards your valuable cargo from impacts, vibrations, and jolts that may occur during long - distance shipping, whether by sea, air, or land. Trust our crates to keep your items in pristine condition throughout the export journey.

Company & Factory

With 200+ employees and a sprawling 12,000㎡ factory in Shaanxi, we've built a robust production ecosystem. Our team of skilled workers, from experienced craftsmen to astute quality inspectors, collaborates seamlessly. Starting with the sourcing of raw materials, we implement rigorous screening procedures. Each batch is tested for its purity and quality. During the production process, at every stage from component manufacturing to final assembly, multiple quality checks are carried out. This ensures that the products leaving our factory not only meet but exceed industry standards, giving our clients unwavering confidence in our offerings.

Customer Visits & Exhibitions

Our expert team will be with you every step of the way, providing in - depth demonstrations and answering all your technical questions. Whether at the expo or in our factory, we're ready to show you why our machines stand out in the market.

FAQs

Q: Can you customize machines for left-handed bending?

A: Yes! We adjust gear configurations for clockwise/counterclockwise operations.

Q: What's the lead time for bulk orders?

A: 15-20 days for 10+ units.

Q: Do you provide CE documentation?

A: Full certification packages are included.

Q: How to maintain the gearbox?

A: Annual lubrication with ISO VG 220 oil – our team guides you.

Q: Payment terms?

A: 30% deposit, 70% before shipment.

Contact Us

Ready to boost productivity? Email sxyongtuo@gmail.com for a quote!

Shaanxi Yongtuo Machinery – Where Innovation Meets Reliability in Reinforcing Steel Crooking Machine Technology.

YOU MAY LIKE

_1744680888628.png)