2.200-ton hydraulic shearing head,high shearing and blanking efficiency.

3.Equipped with automatic tail collection device to reduce work intensity.

4.The collection of finished products is carried out by robots, and the finished products are automatically collected and processed.

5. Large platform-type collecting truck can collect more finished products.

6.A variety of graphic process parameters can be stored in the library, which is convenient and quick to call at anytime.

7. An optional ladder automatic feeding device can be installed to realize automatic feeding of raw materials."

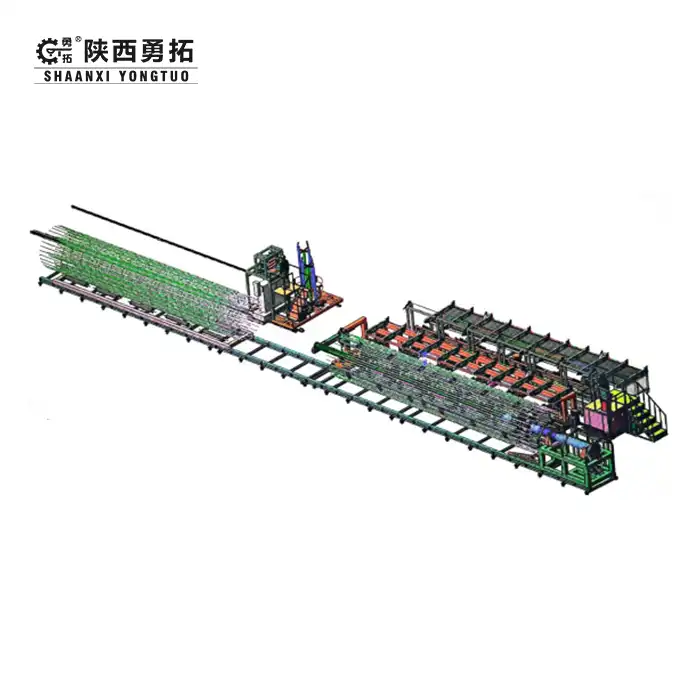

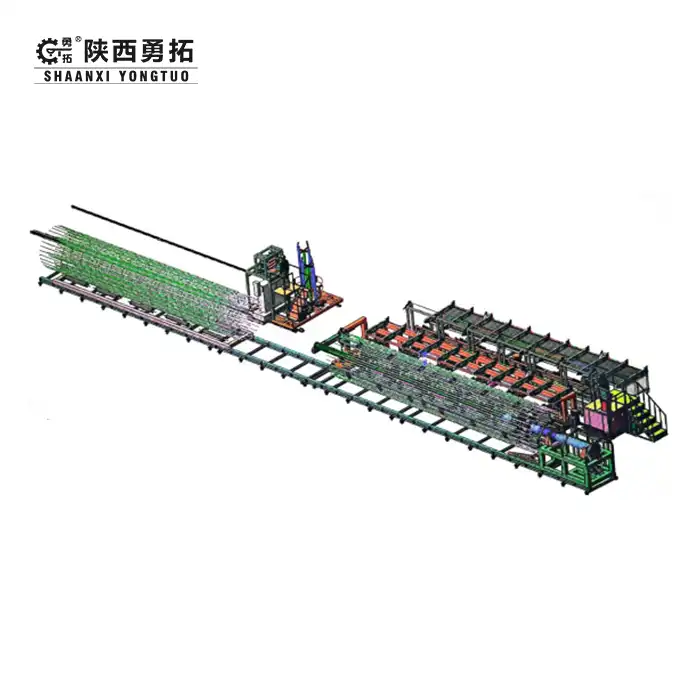

Clever Cutting Bending and Hooking Assembly Line Solution

Shaanxi Yongtuo Machinery Technology Co., Ltd, established in 2003, specializes in manufacturing the Clever Cutting Bending and Hooking Assembly Line – a fully automated system integrating feeding, sizing, shearing, bending, and hooking. With 37 patents and 20+ years of expertise, we deliver precision, energy efficiency, and unmatched reliability for industries like construction, automotive, and aerospace.

Why Choose Us?

✅ 20+ Years of Expertise: Trusted by global clients for industrial automation solutions.

✅ R&D-Driven Innovation: Mature engineering team ensures cutting-edge technology.

✅ 24/7 After-Sales Support: ≤12-hour fault response, remote diagnostics, and on-site maintenance.

✅ Customizable Solutions: Adaptable to your production layout and material specs.

✅ ISO-Certified Quality: Rigorous testing for durability and precision (±0.1mm accuracy).

Key Features & Advantages

- 200-Ton Hydraulic Shearing: High-speed blanking with minimal waste.

- Robotic Collection System: Automates finished product handling, reducing labor costs.

- IoT-Ready Design: Stores 50+ graphic process parameters for quick recall.

- Modular Expandability: Add ladder feeders or vision inspection modules later.

- Energy-Saving Operation: 15% lower power consumption vs. competitors.

Technical Parameters

|

|---|

Applications

Our Clever Cutting Bending and Hooking Assembly Line is ideal for a wide range of industries, ensuring precision and efficiency:

-

Construction: Rebar cages, stirrups, and column ties.

-

Automotive: Exhaust pipes, chassis components.

-

Furniture: Metal frames, decorative curves.

-

Aerospace: Lightweight alloy brackets.

Tailored solutions and customizations are available to fit your specific production needs.

Customization Options

- Adjust platform size for large batches (e.g., 6m truck beds).

- Upgrade to AI-powered defect detection.

- Multi-language control interfaces.

Certifications

- ISO 9001, CE, and TÜV certified.

- Compliant with OSHA and EU noise regulations.

After-Sales Service

- Free Training: On-site operator and technician training.

- 10-Year Spare Parts Guarantee: Global stock warehouses.

- Performance Warranty: 2-year coverage on critical components.

Packaging & Shipping

Our shipping solutions prioritize the safety and traceability of your valuable cargo. Waterproof wrapping, crafted from high - quality, durable materials, shields your items from moisture, whether in transit by sea, air, or land. This is complemented by sturdy steel frame crates, providing robust structural integrity to withstand rough handling. To ensure you're always in the know, we offer GPS - tracked logistics. Through a user - friendly interface, you can access real - time updates on the location and status of your shipment. This transparency allows for better planning and peace of mind, knowing exactly where your goods are at any given moment throughout their journey.

About Shaanxi Yongtuo

Since 2003, we've been at the forefront of CNC bending technology, continuously pushing the boundaries of innovation. Our journey as pioneers has seen us expand our reach far and wide, successfully serving clients in 30+ countries. With over 500 installations across the globe, our machines are hard at work in diverse industries. These successful deployments are a testament to our commitment to quality, as each installation is carefully planned and executed. Our team of experts ensures that every client, from small - scale manufacturers to large - scale industrial enterprises, receives the utmost support, making us a trusted partner in the world of CNC bending technology.

Client Visits & Exhibitions

Our team will be on - hand to showcase our latest and most innovative products. There, you can engage in in - depth discussions, witness live product demonstrations, and explore how our offerings can revolutionize your industrial processes. Similarly, at the Shanghai International Metalworking Fair, we'll display solutions tailored specifically to the metalworking sector. Don't miss this opportunity to connect with us, network with industry peers, and stay ahead of the curve in the fast - paced world of manufacturing.

FAQs

Q: Can it process stainless steel?

A: Yes! Compatible with carbon steel, stainless steel (304/316), and aluminum alloys.

Q: What's the ROI timeline?

A: Clients report 18-24 months via 30% productivity gains.

Q: Do you offer installation?

A: Yes – our engineers handle setup and calibration.

Q: How to adjust bending angles?

A: Pre-set via touchscreen; takes <2 minutes.

Q: Spare parts availability?

A: 85% of parts shipped within 48 hours globally.

Boost Your Production with the Clever Cutting Bending and Hooking Assembly Line!

📧 Email: sxyongtuo@gmail.com

YOU MAY LIKE

_1744680888628.png)