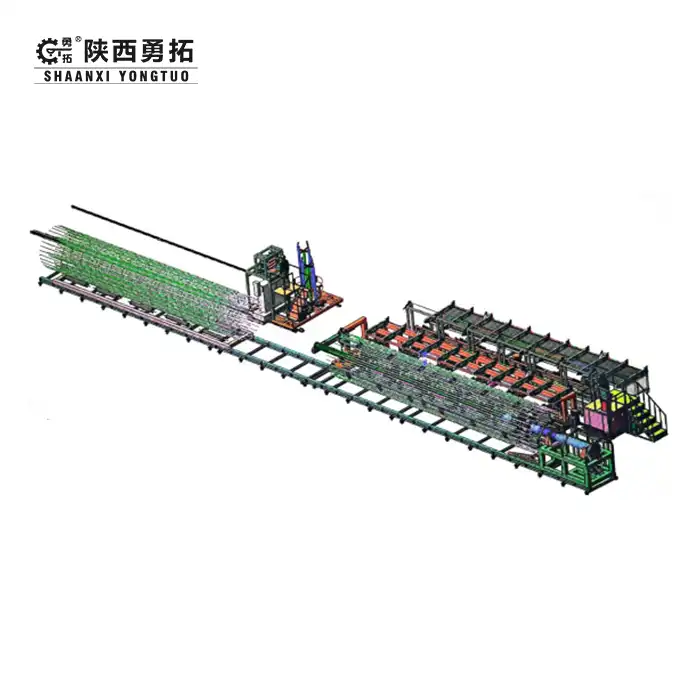

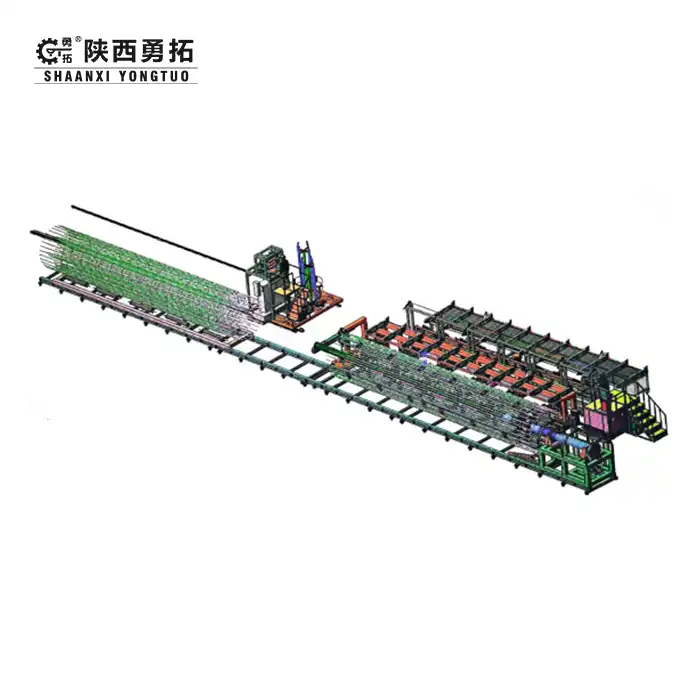

2. Automatic loading, distribution, positioning, indexing and welding of main ribs.

3. There is no need to replace the holding mold when processing 1200-2200mm steel cages, and it is easy to use for odd jobs.

4. The processing of steel cage frame and winding bar processing are carried out at the same time to increase production efficiency."

Clever Steel Cage Assembly Production Line | Shaanxi Yongtuo Machinery

Shaanxi Yongtuo Machinery Technology Co., Ltd, established in 2003, is a trusted Clever Steel Cage Assembly Production Line manufacturer with 37 patents and 20+ years of export expertise. Our automated systems empower construction, energy, and manufacturing industries to achieve 45% faster production cycles while reducing labor costs by 60%. Discover how our PLC-controlled smart assembly line redefines precision and efficiency for steel cage fabrication.

Why Choose Our product?

- ✅ 1-Click Size Switching: Process 1200-2200mm cages without mold changes

- ✅ Dual-Task Operation: Simultaneous frame building & spiral rod welding

- ✅ 24/7 Support: ≤12-hour on-site response with remote diagnostics

- ✅ Energy Savings: 30% lower power consumption vs competitors

- ✅ ISO 1461 Certified: Salt spray resistance ≥1,500 hours

Smart Features & Competitive Advantages

- 🔧 PLC-Integrated Control: Full automation from loading to welding

- 🔧 Error-Proof Positioning: ±0.5mm main rib alignment accuracy

- 🔧 Modular Design: Add AI vision or IoT sensors later

- 🔧 MES Compatibility: Real-time OEE tracking via SQL/OPC UA

- 🔧 CE & GOST Certified: Ready for global deployment

Technical Specifications

|

Where Our Production Line Excels?

Our Clever Steel Cage Assembly Production Line delivers unmatched performance across a wide range of demanding applications. Engineered for both scale and precision:

🏗️ Bridge Pile Cages — Fully compliant with ISO 17744 for infrastructure durability

🔋 Battery Module Frames — High consistency for precision energy systems

🛢️ Oil & Gas Reinforcement — Withstands harsh field conditions and deep-well stress

🚇 Tunnel Support Structures — Engineered for stability in complex underground builds

🏭 Precast Concrete Production — High-speed cycles for modular construction demands

Whether you're building metro lines, offshore wind platforms, or high-rise foundations, Yongtuo’s production line ensures high throughput, ultra-low error margins, and seamless integration with modern digital workflows.

Tailored Solutions for Your Needs

Our steel cage manufacturing equipment offers remarkable versatility. With a cage diameter range spanning from 600 - 3000mm, it caters to diverse project requirements, whether for small - scale construction or large - scale infrastructure projects. In terms of power supply, we provide multiple voltage options including 220V, 440V, and 575V, ensuring compatibility with different regional electrical systems. For enhanced automation, you have the option to add robotic labeling and palletizing features. This streamlines the post - production process, increasing efficiency and reducing manual labor. Complementing these features is our multi - language HMI interface. Operators from around the world can easily navigate the system, as it supports languages such as English, Spanish, Chinese, and more, making our equipment user - friendly on a global scale.

Proven Reliability Backed By

Our products are backed by a comprehensive set of industry - recognized accreditations. Holding CE, ISO 9001, and SIL - 2 certifications, we ensure compliance with strict European safety standards, maintain a world - class quality management system, and meet high - level safety integrity requirements. With 12 overseas service centers strategically located across the globe, we are always within reach. Whether it's routine maintenance, technical advice, or emergency repairs, our expert teams can quickly respond. To top it off, we offer a generous 2 - year mechanical warranty. This gives our customers peace of mind, knowing that their investment is protected against mechanical failures during this period, and allowing them to focus on their operations without worry.

Your Production, Our Priority

From installation training to preventive maintenance, we provide:

- 📞 24/7 multilingual tech support

- 🔧 Spare parts delivery within 48 hours

- 📊 Annual efficiency optimization reports

FAQ:

Q1: Can your equipment handle non-standard or irregular cage shapes?

A: Yes. Our servo-controlled mandrel and adaptive welding heads automatically adjust to variable cage diameters and lengths via programmable recipes.

Q2: Is your system compatible with existing ERP or MES platforms?

A: Absolutely. We offer API and SDK integration for SAP, Oracle, and custom systems. Real-time data exchange supports OEE tracking, inventory sync, and production planning.

Q3: What’s the typical installation and commissioning time?

A: Standard installation takes 10–15 days, including on-site setup and operator training under our guided commissioning program.

Q4: What’s the minimum order quantity (MOQ)?

A: MOQ is 1 unit. We also offer discounted pricing for orders of 3 or more production lines.

See It in Action

Book a live demo at our Xi'an facility or request a virtual tour.

Ready to upgrade your steel cage production? Contact our engineers at sxyongtuo@gmail.com for a free ROI analysis. Experience why global leaders trust Shaanxi Yongtuo's Clever Steel Cage Assembly Production Line for mission-critical operations.

YOU MAY LIKE

_1744680888628.png)