2.The internal gear adopts helical gear meshing technology for ultra-quiet and stable operation.

3.Forged crankshaft, tool holder, customized 55sicr blade, M10 enlarged traveling gear, not easy to lose gears during short-term overload work.

4.The fuselage design has the knife edge slightly raised to improve the oil leakage defect.

5.The casing is thickened, and the side cover is built into the casing to prevent it from loosening."

Shaanxi Yongtuo Machinery Technology Co., Ltd: Your Trusted Wire Rod Straightening Machine Manufacturer

At Shaanxi Yongtuo Machinery Technology Co., Ltd, we pride ourselves on being a leading manufacturer and supplier of high-quality wire rod straightening machines. With our cutting-edge technology and commitment to innovation, we offer unparalleled advantages in efficiency, precision, and reliability, making us the go-to choice for businesses worldwide.

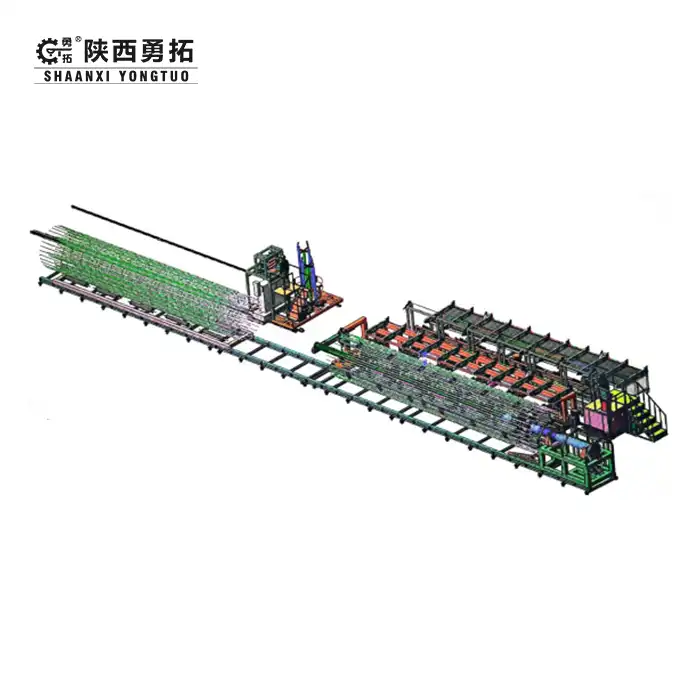

Product Introduction: Revolutionary Wire Rod Straightening Machine

Our state-of-the-art product is designed to meet the diverse needs of modern manufacturing processes. This advanced equipment combines robust construction with intelligent features, ensuring optimal performance and consistent results. Whether you're working with various wire diameters or different materials, our machine delivers exceptional straightening and cutting accuracy, minimizing waste and maximizing productivity.

Parameters

Why Choose Our Wire Rod Straightening Machine?

- Unmatched Efficiency: Our machine's high-speed processing capabilities ensure rapid production, boosting your overall output.

- Superior Precision: Achieve consistent straightening results and accurate length cutting, reducing material waste and improving product quality.

- Durability and Reliability: Built to withstand continuous operation, our machine requires minimal maintenance, ensuring long-term performance.

- Smart Integration: Seamlessly connect with Industry 4.0 technologies for remote monitoring, control, and data analysis.

- Customizable Solutions: Our modular design allows for easy upgrades and modifications to suit your specific production requirements.

- Energy-Efficient Operation: Engineered to minimize power consumption without compromising on performance.

- Enhanced Safety Features: Compliant with international safety standards to protect your operators and maintain a secure working environment.

- User-Friendly Interface: Intuitive controls and easy setup reduce training time and streamline operations.

- Comprehensive Support: Benefit from our extensive warranty, readily available spare parts, and quick technical assistance.

- Cost-Effective Investment: Competitive pricing and low total cost of ownership ensure a rapid return on your investment.

Application Areas

Our versatile wire rod straightening machine finds applications across various industries, including:

- Construction: Rebar processing for reinforced concrete structures

- Manufacturing: Production of industrial components and fasteners

- Automotive: Wire forming for vehicle parts and accessories

- Aerospace: Precision wire straightening for critical components

- Energy: Cable and wire production for power transmission

- Agriculture: Fencing and support structure manufacturing

Product Display

Contact us to see high-quality demonstrations of our Wire Rod Straightening Machine in action.

After-Sales Service

We're committed to your success long after the purchase. Our comprehensive after-sales service includes:

- Installation and commissioning support

- Operator training programs

- Regular maintenance checks

- 24/7 technical support

- Rapid response to service requests

- Continuous software updates

Exhibitions

Visit us at upcoming trade shows to experience our wire rod straightening machines firsthand.

Customer Visits

Schedule a visit to our facility to see our machines in production and discuss your needs with our experts.

FAQ

Q: How often does the product require maintenance?

A: Our machine is designed for minimal maintenance, typically requiring only routine checks every 500 operating hours.

Q: Can the machine handle different wire materials?

A: Yes, our product is versatile and can process various materials, including carbon steel, stainless steel, and alloy wires.

Q: Is the control system compatible with our existing production management software?

A: Absolutely! Our PLC-based control system can be easily integrated with most standard production management platforms.

Q: What kind of warranty do you offer?

A: We provide a comprehensive 2-year warranty on all major components, with options for extended coverage.

Q: How quickly can you provide spare parts if needed?

A: We maintain a robust inventory of spare parts and can typically ship within 24-48 hours of receiving an order.

Contact Us

Ready to revolutionize your wire processing capabilities? Contact our expert team today to learn more about our wire rod straightening machine and how it can benefit your business.

Email: sxyongtuo@gmail.com

Experience the Shaanxi Yongtuo difference – where innovation meets precision in wire rod straightening technology.

YOU MAY LIKE

_1744680888628.png)