2.The reducer adopts planetary reducer, which has high transmission accuracy and long service life.

3.The gear is made of 20CrMnTi material, with a carburizing hardness of HRC58-62 and a longer service life.

4.The arc rolling wheel is made of Cr12MoV mold steel, with a vacuum quenching hardness of HRC58-62 and is durable.

5. Heightened driving wheel design can process multiple steel bars at one time.

6. The hand wheel reducer drives the arc pressing wheel, which is easy and quick to operate.

7. Double support panels control the stability of rolling arcs of multiple steel bars.

8.Thickened panel increases equipment stability."

Shaanxi Yongtuo: Your Trusted Metal Bar Bending Machine Manufacturer

Shaanxi Yongtuo Machinery Technology Co., Ltd, established in 2003, specializes in advanced metal bar bending machines designed for industries requiring high precision and reliability. With 37 patents, a mature R&D team, and a global export network, we deliver energy-efficient, user-friendly solutions backed by 24/7 support.

Why Choose Our Metal Bar Bending Machine?

✅ 20+ Years of Expertise: Trusted by 10,000+ clients worldwide

✅ Advanced CNC Technology: Achieve ±0.1mm precision for complex bends.

✅ Energy-Saving Design: 11KW variable frequency motor reduces power consumption by 15%.

✅ Global Certifications: CE, ISO 9001, and SGS compliance.

✅ 24/7 After-Sales: ≤12-hour fault response, on-site maintenance.

Features & Advantages

- Robust Construction: Arc rollers made of Cr12MoV mold steel (HRC58-62 hardness) resist wear.

- Planetary Reducer: Enhances torque accuracy and extends lifespan.

- Multi-Bar Processing: Heightened driving wheels bend 5-8 bars simultaneously.

- User-Friendly: Hand wheel reducer for quick adjustments.

- Double Support Panels: Ensure stability during high-load operations.

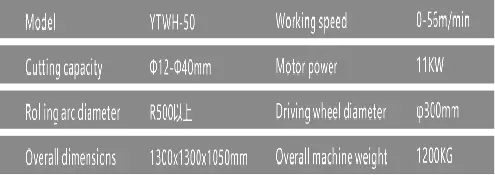

Product Parameters

|

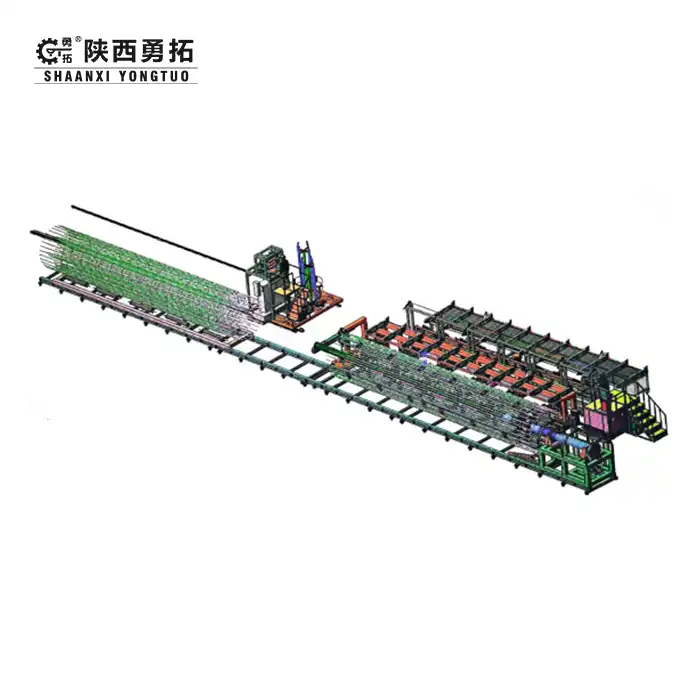

Product Structure

Our Metal Bar Bending Machine is built for precision and durability with key components including:

-

CNC Control Panel: Easy-to-use interface for precise adjustments.

-

Arc Rollers: Made from Cr12MoV steel (HRC58-62) for wear resistance.

-

Planetary Reducer: Ensures smooth operation and extended lifespan.

-

Adjustable Support Panels: Provide stability during heavy operations.

-

Multi-Bar Processing Wheels: Bend 5-8 bars simultaneously for higher efficiency.

Designed for high-precision bending, energy efficiency, and user-friendly operation, making it perfect for automotive, construction, aerospace, and energy industries.

Application Areas

- Automotive: Precision bends for exhaust systems, chassis.

- Construction: Reinforced steel bars for bridges, buildings.

- Aerospace: High-tolerance aluminum/steel components.

- Energy: Pipe brackets, turbine parts.

Customization Options

Tailor your machine with:

- Extended roller lengths (up to 3m).

- Custom bend angles (30°–180°).

- PLC programming for automated workflows.

Certifications

✔️ ISO 9001 ✔️ CE ✔️ SGS ✔️ TÜV

After-Sales Service

- Free Remote Diagnosis: 24/7 technical support via video call.

- Spare Parts Guarantee: 10-year availability.

- On-Site Training: 3-day operator certification program.

Packaging & Delivery

Machines are crated in anti-rust treated, shock-absorbent wooden frames. Delivered in 15–25 days.

Company Introduction

Founded in 2003, Shaanxi Yongtuo serves 50+ countries with CNC bending equipment. Our 200-acre factory integrates R&D, testing, and production under one roof.

Factory Tour

Video link: Automated assembly lines, laser calibration labs, and QA inspection zones.

Customer Visits

Our ability to meet their exacting standards, from strict quality requirements to timely delivery, has made us a trusted partner for both Thai automotive and German railway enterprises.

Exhibitions

At our booth, you'll discover our latest and most innovative products and services. Our team of experts will be on - hand to provide detailed demonstrations, answer your questions, and discuss how our solutions can benefit your business. Whether you're in manufacturing, engineering, or looking for cutting - edge technology, this is the perfect opportunity to network, gain insights, and explore new possibilities. Don't miss out on this chance to engage with us and be at the forefront of industrial innovation.

FAQs

Q: Can this machine bend stainless steel?

A: Yes! It handles stainless steel, aluminum, and carbon steel up to HRC45 hardness.

Q: Do you provide installation guidance?

A: Absolutely – we offer free video manuals and optional on-site setup.

Q: What's the warranty period?

A: 2 years for the main frame, 1 year for electronic parts.

Q: Can I get a sample test before bulk order?

A: Yes – contact us to schedule a factory trial.

Q: How do I maintain the machine?

A: Monthly greasing of gears and annual reducer checks ensure longevity.

Contact Us for Your product Needs!

📧 Email: sxyongtuo@gmail.com

Let’s build the future of infrastructure together—with precision, efficiency, and trusted collaboration.

YOU MAY LIKE

_1744680888628.png)